Home>Technology>Smart Home Devices>How Often Should You Change 3D Printer Nozzle

Smart Home Devices

How Often Should You Change 3D Printer Nozzle

Modified: January 9, 2024

Find out how often you should change your 3D printer nozzle for optimal performance. Get expert tips on maintaining your smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

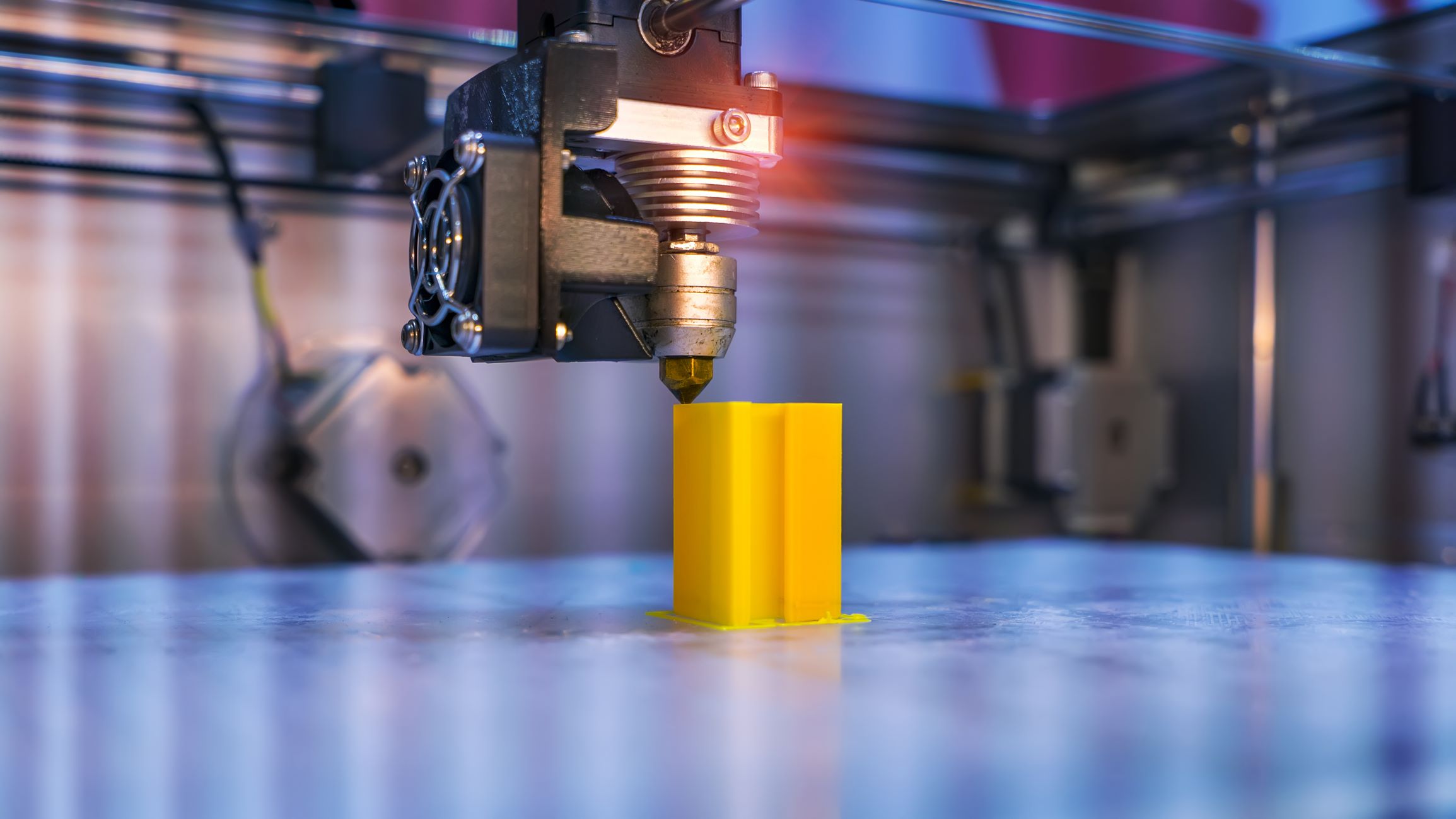

Welcome to the exciting world of 3D printing! Whether you are a novice or a seasoned enthusiast, you understand the crucial role that a 3D printer nozzle plays in the quality and precision of your prints. The nozzle is the gateway through which molten filament is extruded, shaping your creations layer by layer. However, like any component subject to wear and tear, the nozzle requires periodic attention to maintain optimal performance. In this article, we will delve into the factors influencing the lifespan of a 3D printer nozzle, the telltale signs indicating the need for a replacement, and the recommended frequency for changing the nozzle. By the end, you will possess a comprehensive understanding of how often you should change your 3D printer nozzle, empowering you to achieve exceptional print results and prolong the longevity of your 3D printing endeavors. So, let's embark on this enlightening exploration into the world of 3D printer maintenance and optimization!

Key Takeaways:

- 3D printer nozzles should be changed every 3,000 to 5,000 printing hours for standard brass nozzles. However, this may vary based on filament type, usage intensity, and maintenance diligence.

- Signs that your 3D printer nozzle needs changing include extrusion irregularities, poor print surface quality, clogging, filament wear, and inconsistent layer adhesion. Timely recognition of these signs is crucial for maintaining print quality.

Read more: How To Unclog A 3D Printer Nozzle

Factors Affecting Nozzle Lifespan

Several factors influence the lifespan of a 3D printer nozzle, impacting its durability and performance. Understanding these factors is instrumental in determining the frequency of nozzle changes and optimizing your 3D printing experience. Let’s explore the key elements that affect the longevity of your 3D printer nozzle:

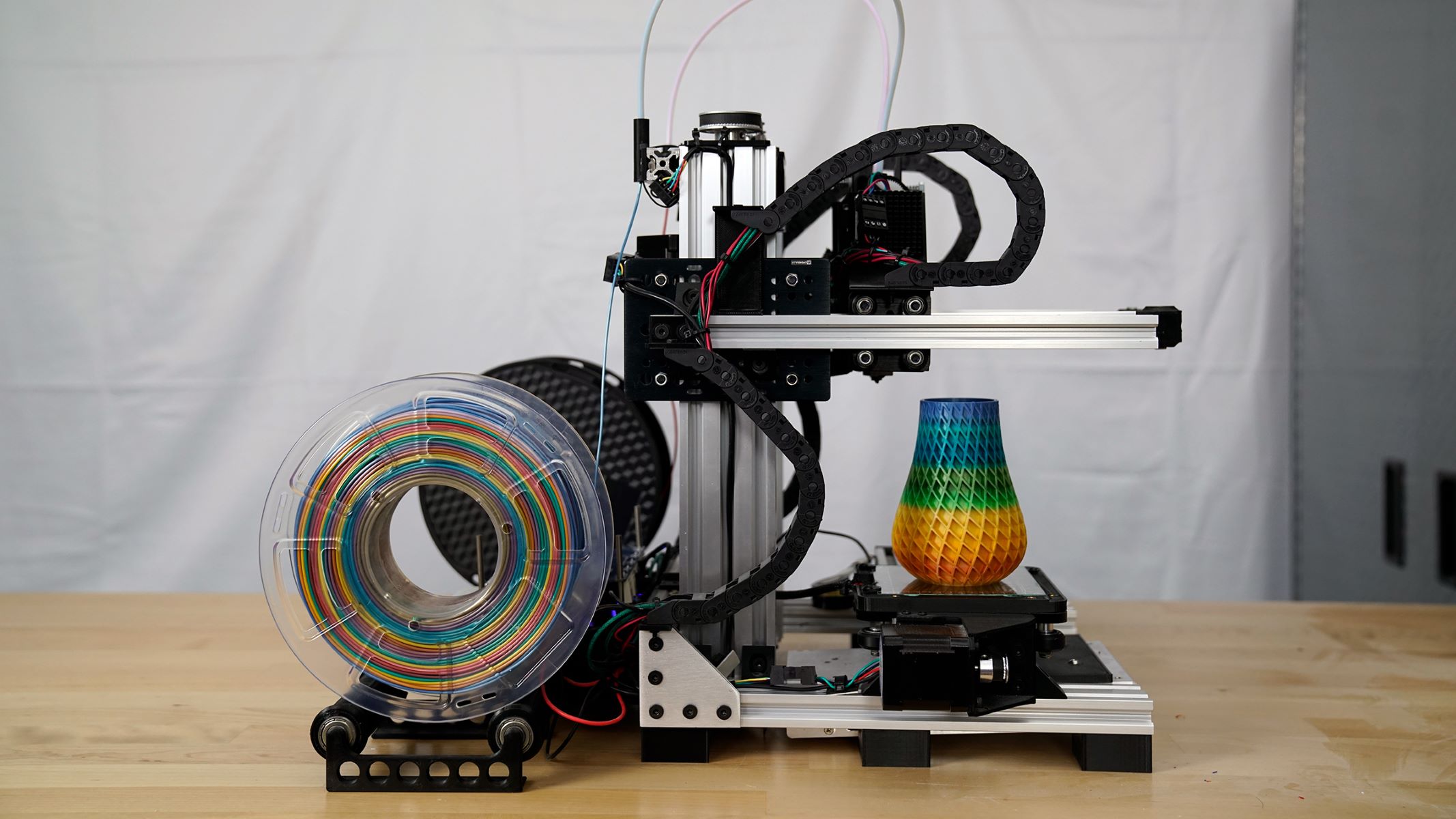

- Filament Material: The type of filament used significantly impacts the wear and tear experienced by the nozzle. Abrasive materials such as carbon fiber, metal-infused, or glow-in-the-dark filaments tend to accelerate nozzle degradation due to their abrasive nature. In contrast, standard PLA and ABS filaments exert less strain on the nozzle, prolonging its lifespan.

- Printing Temperature: The temperature at which you operate your 3D printer plays a pivotal role in nozzle longevity. Consistently printing at high temperatures, especially above the recommended threshold for the specific nozzle material, can expedite wear and lead to nozzle degradation. It is essential to adhere to the manufacturer’s temperature guidelines to preserve the integrity of the nozzle.

- Printing Speed and Frequency: The speed at which you print and the frequency of usage impact the nozzle’s wear rate. High-speed printing and continuous, prolonged usage can subject the nozzle to increased stress, potentially shortening its lifespan. Monitoring and adjusting the printing speed and frequency can help mitigate excessive wear on the nozzle.

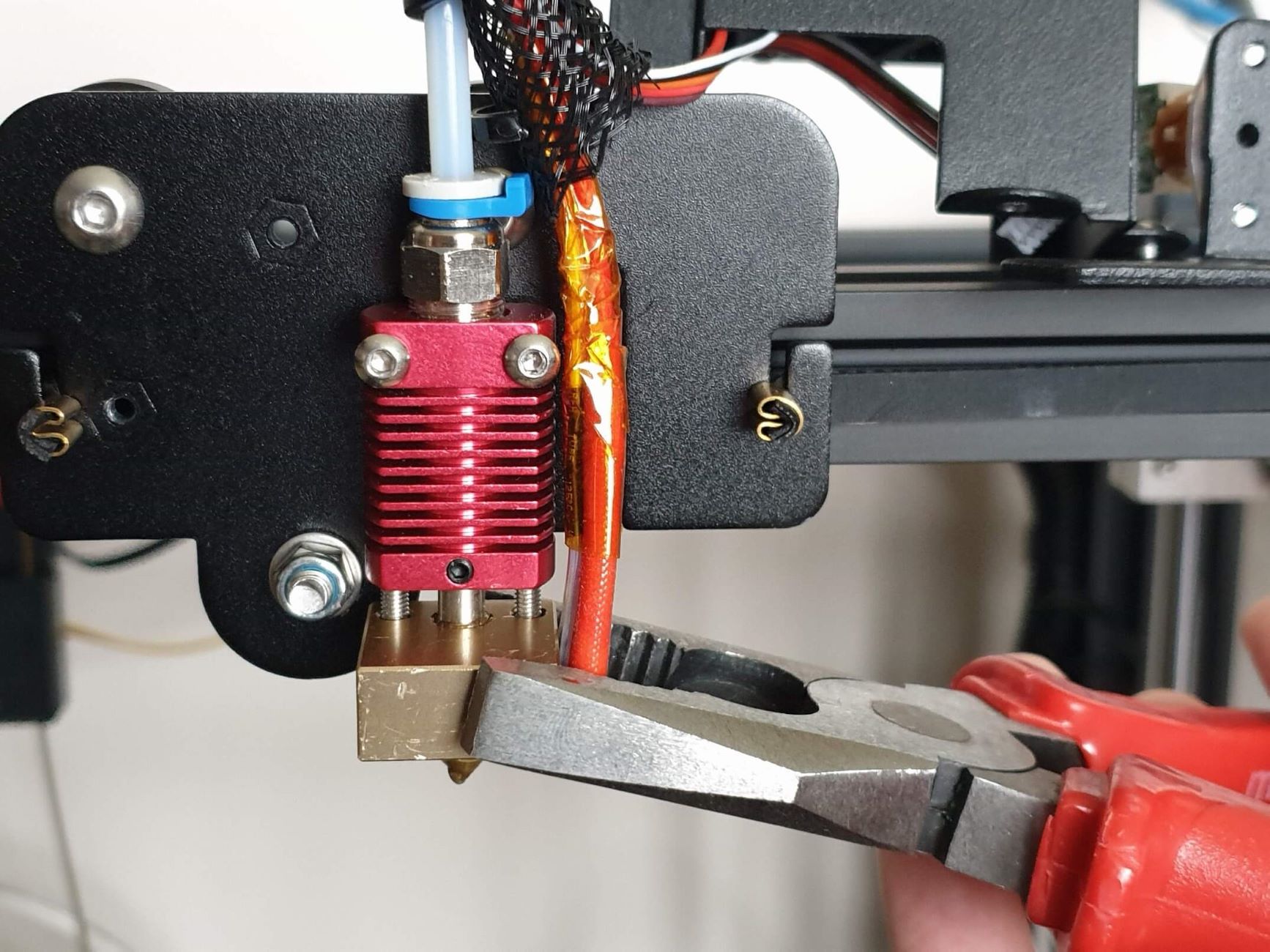

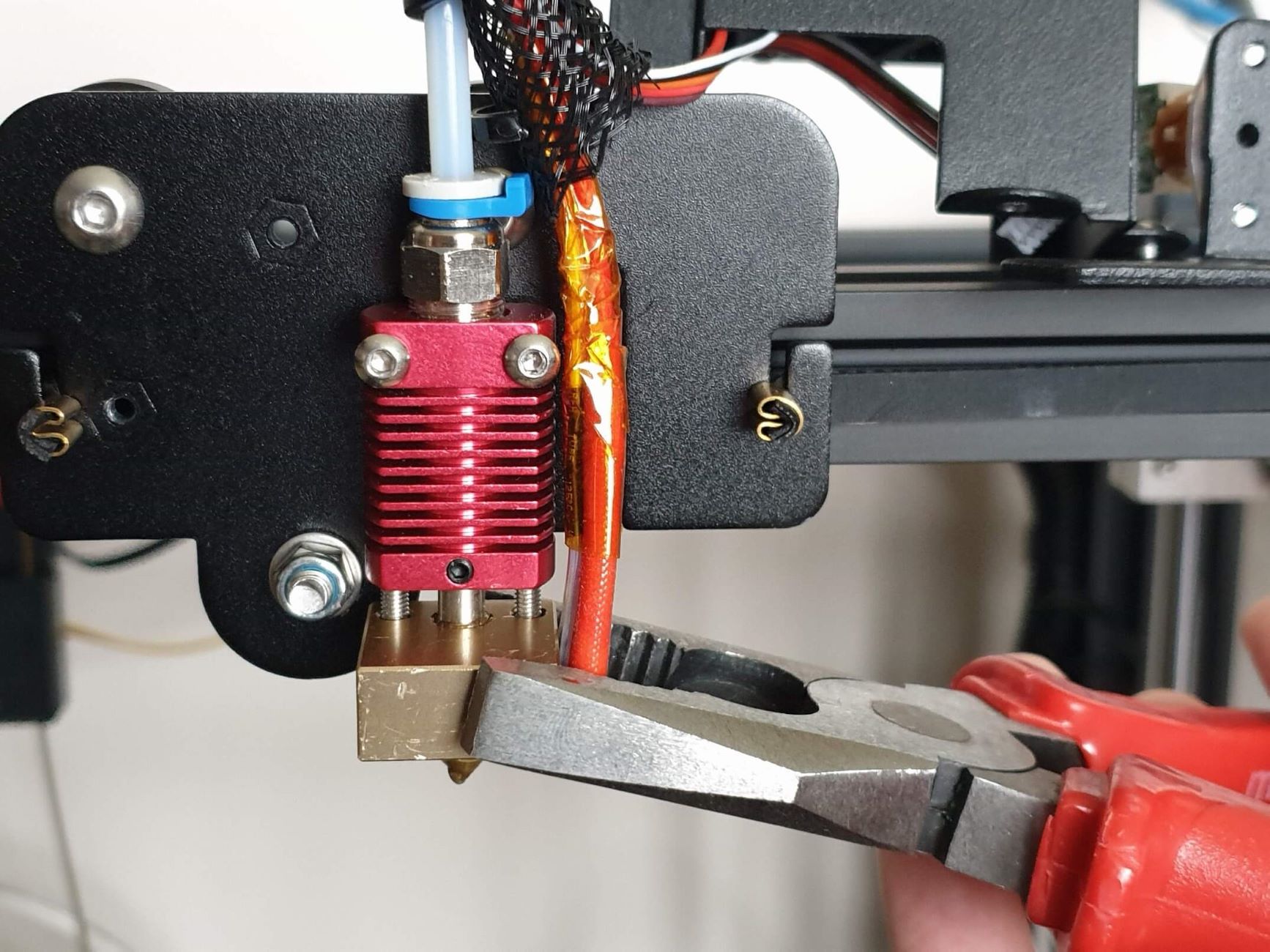

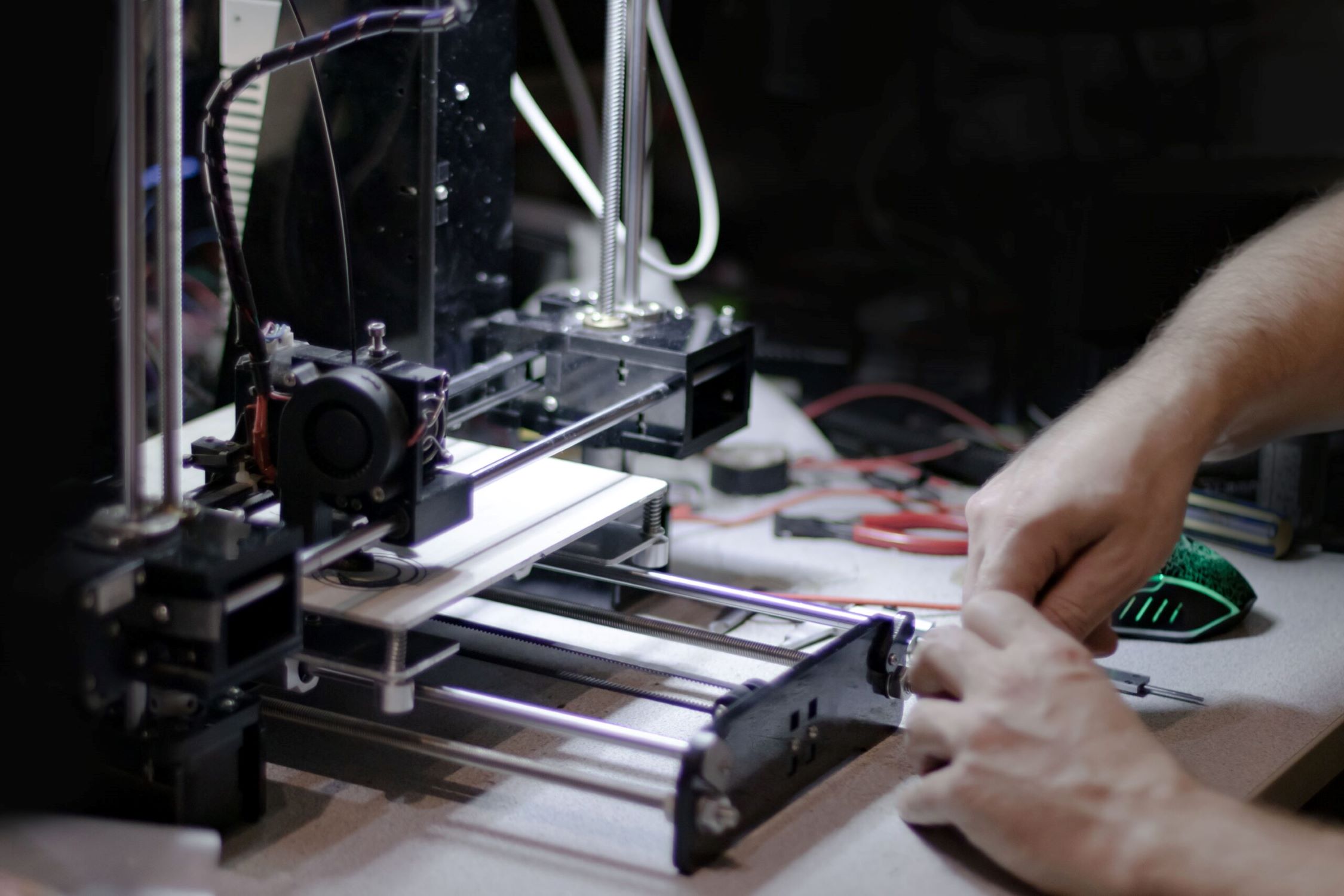

- Maintenance and Cleaning: Regular maintenance and cleaning practices significantly influence the nozzle’s durability. Proper maintenance, including periodic cleaning to remove any accumulated debris or filament residue, can prevent clogging and maintain the nozzle’s performance. Neglecting maintenance can lead to clogs and decreased print quality, necessitating premature nozzle replacement.

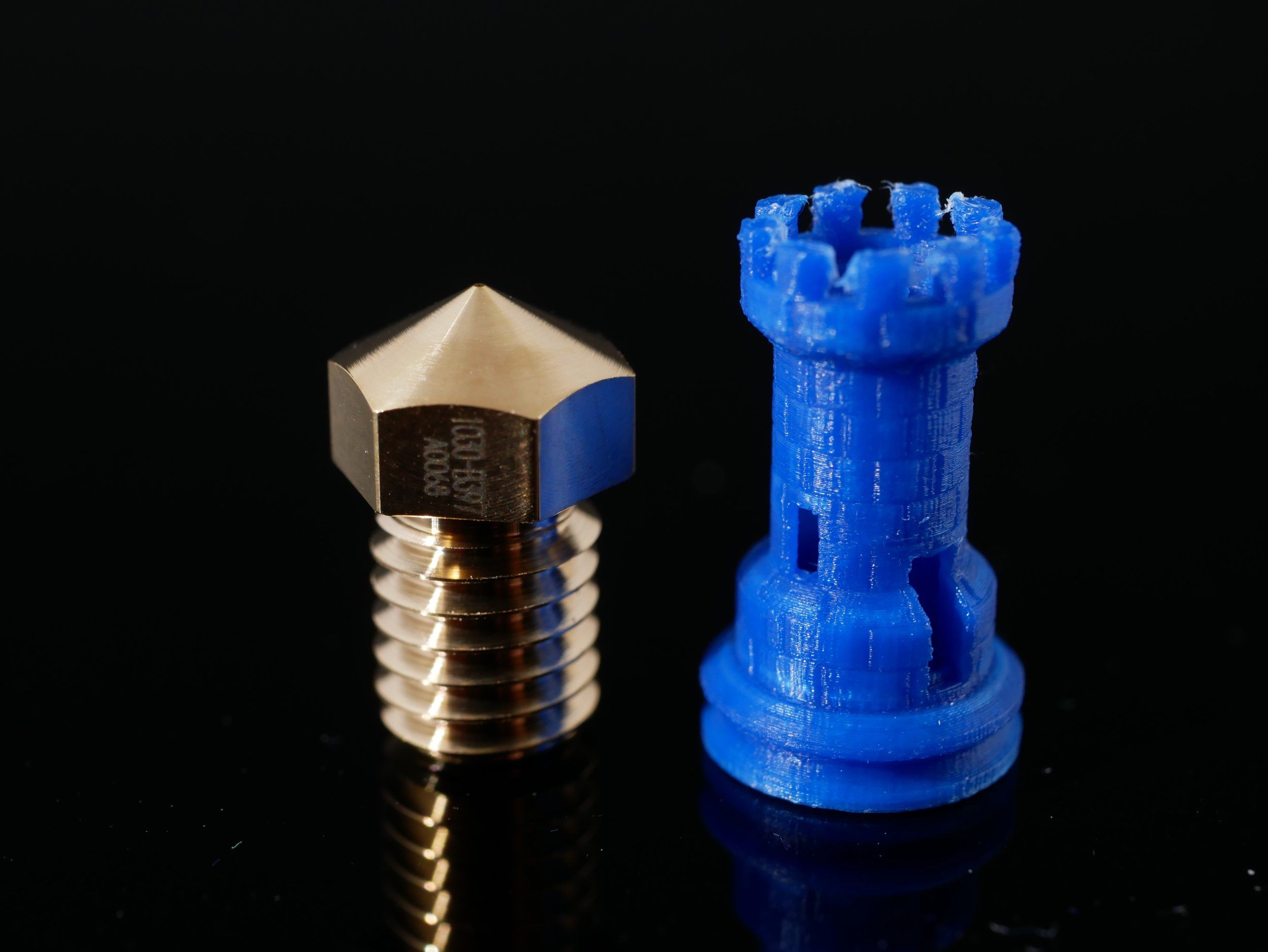

- Nozzle Material and Quality: The material composition and quality of the nozzle itself are crucial determinants of its lifespan. Nozzles crafted from hardened steel or other durable materials exhibit greater resistance to wear, offering extended longevity compared to standard brass nozzles. Investing in high-quality, durable nozzles can mitigate the frequency of replacements.

By comprehending these influential factors, you can proactively address nozzle longevity and optimize your 3D printing processes. The interplay of filament material, printing temperature, speed and frequency, maintenance practices, and nozzle material underscores the multifaceted nature of nozzle lifespan management. Armed with this knowledge, you are better equipped to make informed decisions regarding the maintenance and replacement of your 3D printer nozzle.

Signs That Your Nozzle Needs Changing

Recognizing the indications signaling the need for a 3D printer nozzle replacement is essential for maintaining print quality and preventing potential issues. Here are the telltale signs that your nozzle requires changing:

- Extrusion Irregularities: If you notice inconsistent extrusion, such as under-extrusion (gaps in printed layers) or over-extrusion (excessive material deposition), it may signify nozzle wear or clogging. Inadequate filament flow can compromise print precision and structural integrity, necessitating nozzle inspection and potential replacement.

- Poor Print Surface Quality: A decline in print surface quality, characterized by rough textures, uneven layers, or surface imperfections, can be attributed to a deteriorating nozzle. As the nozzle wears, it may struggle to maintain precise filament deposition, resulting in compromised print aesthetics and structural integrity.

- Clogging and Filament Residue: Persistent nozzle clogging or the presence of filament residue around the nozzle’s orifice indicates potential nozzle degradation. Clogs hinder filament flow and disrupt print consistency, highlighting the need for nozzle assessment and potential replacement to restore optimal functionality.

- Filament Abrasion and Discoloration: Abrasive filaments can accelerate nozzle wear, leading to visible abrasion or discoloration on the nozzle’s tip. If you observe signs of filament-induced wear or discoloration, it is advisable to evaluate the nozzle’s condition and consider replacing it to maintain print quality and nozzle integrity.

- Inconsistent Layer Adhesion: Fluctuations in layer adhesion, manifested as delamination or weak bonding between printed layers, may indicate nozzle-related issues. Inadequate nozzle performance can compromise layer fusion, resulting in structural weaknesses within the print. Assessing the nozzle’s condition is crucial to rectify these inconsistencies.

By attentively monitoring these signs, you can proactively address nozzle-related issues and uphold the quality and precision of your 3D prints. Timely recognition of extrusion irregularities, print surface anomalies, clogging, filament wear, and layer adhesion inconsistencies empowers you to take corrective measures, including potential nozzle replacement, to sustain optimal 3D printing outcomes.

It is recommended to change your 3D printer nozzle every 3-6 months, or sooner if you notice decreased print quality or clogging. Regular maintenance will ensure better printing results.

Recommended Frequency for Nozzle Changes

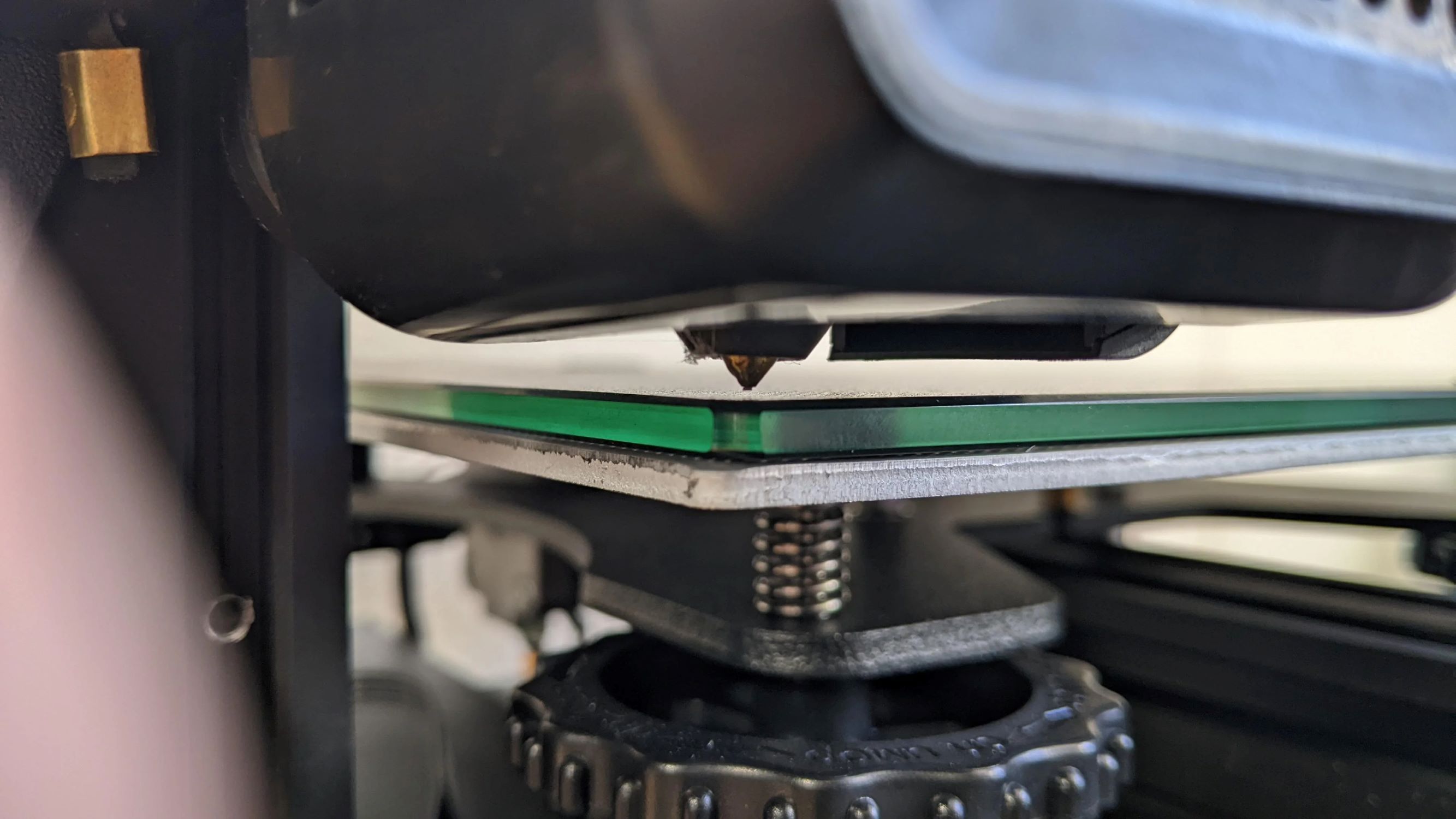

Determining the optimal frequency for changing your 3D printer nozzle is a pivotal aspect of nozzle maintenance and print quality management. While the frequency can vary based on usage, filament types, and printing parameters, establishing general guidelines can aid in preserving nozzle functionality and print precision. Here are essential considerations for determining the recommended frequency for nozzle changes:

- Usage Intensity: The frequency of nozzle changes is influenced by the intensity and duration of 3D printer usage. For avid users or industrial settings with continuous printing, more frequent nozzle changes may be necessary to mitigate wear and ensure consistent print quality. Conversely, occasional hobbyist use may warrant less frequent nozzle replacements.

- Filament Abrasiveness: The abrasive nature of the filaments utilized significantly impacts the nozzle’s wear rate. Employing abrasive filaments, such as carbon fiber-infused or metallic filaments, accelerates nozzle degradation, necessitating more frequent replacements compared to standard filaments like PLA or ABS.

- Print Temperature and Speed: Operating your 3D printer at high temperatures or utilizing high-speed printing settings can expedite nozzle wear. Monitoring and adjusting these parameters, along with periodic nozzle inspections, can help gauge the appropriate frequency for nozzle changes based on wear and performance.

- Regular Maintenance: Adhering to a consistent maintenance regimen, including nozzle cleaning and upkeep, can extend the nozzle’s lifespan. Proactive maintenance practices can mitigate the need for frequent replacements, contributing to sustained nozzle performance and print quality.

- Nozzle Material and Quality: The choice of nozzle material and its quality profoundly impacts its durability. Investing in high-quality, wear-resistant nozzles, such as those crafted from hardened steel, can reduce the frequency of replacements compared to standard brass nozzles, providing long-term cost-efficiency and sustained print quality.

Considering these factors, a general recommendation for nozzle changes ranges from every 3,000 to 5,000 printing hours for standard brass nozzles under normal usage conditions. However, this estimate is contingent on the aforementioned variables and may require adjustment based on individual printing environments and practices. For users employing abrasive filaments or operating under high-stress printing conditions, more frequent nozzle changes, potentially ranging from 1,000 to 3,000 printing hours, may be warranted to uphold print quality and nozzle integrity.

Ultimately, attentive monitoring of print quality, filament performance, and nozzle condition, coupled with periodic inspections and maintenance, is crucial in determining the ideal frequency for nozzle changes. By aligning the replacement intervals with usage patterns, filament characteristics, and maintenance diligence, you can optimize nozzle longevity and sustain exceptional 3D printing outcomes.

Conclusion

Embarking on the journey of 3D printing entails not only unleashing your creativity but also embracing the responsibility of maintaining and optimizing the essential components of your 3D printer. The nozzle, serving as the conduit for material extrusion, plays a pivotal role in shaping the quality and precision of your prints. As we conclude our exploration into the frequency of 3D printer nozzle changes, it is evident that a nuanced understanding of the factors influencing nozzle lifespan, coupled with vigilant observation of telltale signs, is paramount in preserving print quality and nozzle functionality.

By comprehending the influential factors, including filament material, printing parameters, maintenance practices, and nozzle quality, you are equipped to make informed decisions regarding the frequency of nozzle changes. Whether you are an avid enthusiast immersed in continuous printing endeavors or an occasional hobbyist exploring the realms of 3D creation, adapting the recommended frequency for nozzle changes to align with your usage patterns and filament characteristics is essential in sustaining optimal print quality and nozzle integrity.

Furthermore, the proactive recognition of signs indicating the need for nozzle replacement, such as extrusion irregularities, poor print surface quality, and filament wear, empowers you to address potential issues expediently, ensuring consistent print precision and structural integrity. Timely nozzle changes, guided by usage intensity, filament abrasiveness, and maintenance diligence, serve as a cornerstone in preserving the longevity of your 3D printer and elevating the quality of your creations.

As you navigate the dynamic landscape of 3D printing, remember that the frequency of nozzle changes is not merely a maintenance task but a strategic endeavor to uphold the excellence of your prints. Embrace the synergy of knowledge, observation, and proactive maintenance to optimize your 3D printing experience, and let your creativity flourish unhindered by nozzle-related constraints. With a discerning eye and a proactive approach, you are poised to unlock the full potential of your 3D printer, yielding remarkable creations that embody precision, innovation, and ingenuity.

So, as you embark on your next 3D printing venture, may your nozzles be pristine, your prints impeccable, and your creativity boundless. Happy printing!

Frequently Asked Questions about How Often Should You Change 3D Printer Nozzle

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Often Should You Change 3D Printer Nozzle”