Home>Technology>Smart Home Devices>How To Determine Nozzle Size In 3D Printer

Smart Home Devices

How To Determine Nozzle Size In 3D Printer

Published: January 10, 2024

Learn how to calculate the ideal nozzle size for your 3D printer to achieve precision and quality prints. Find out the best practices for choosing the right nozzle size. Ideal for smart home device enthusiasts.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

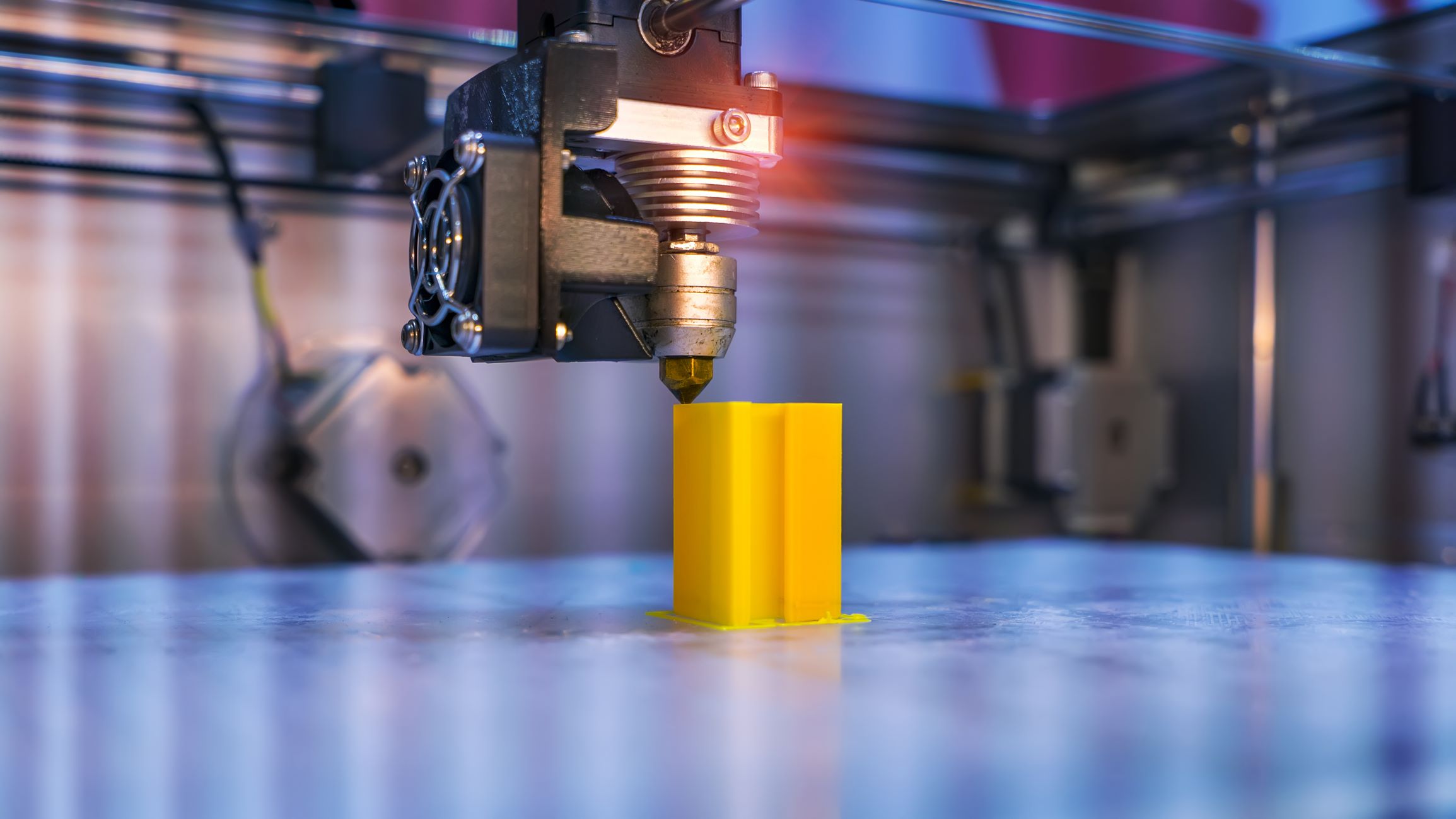

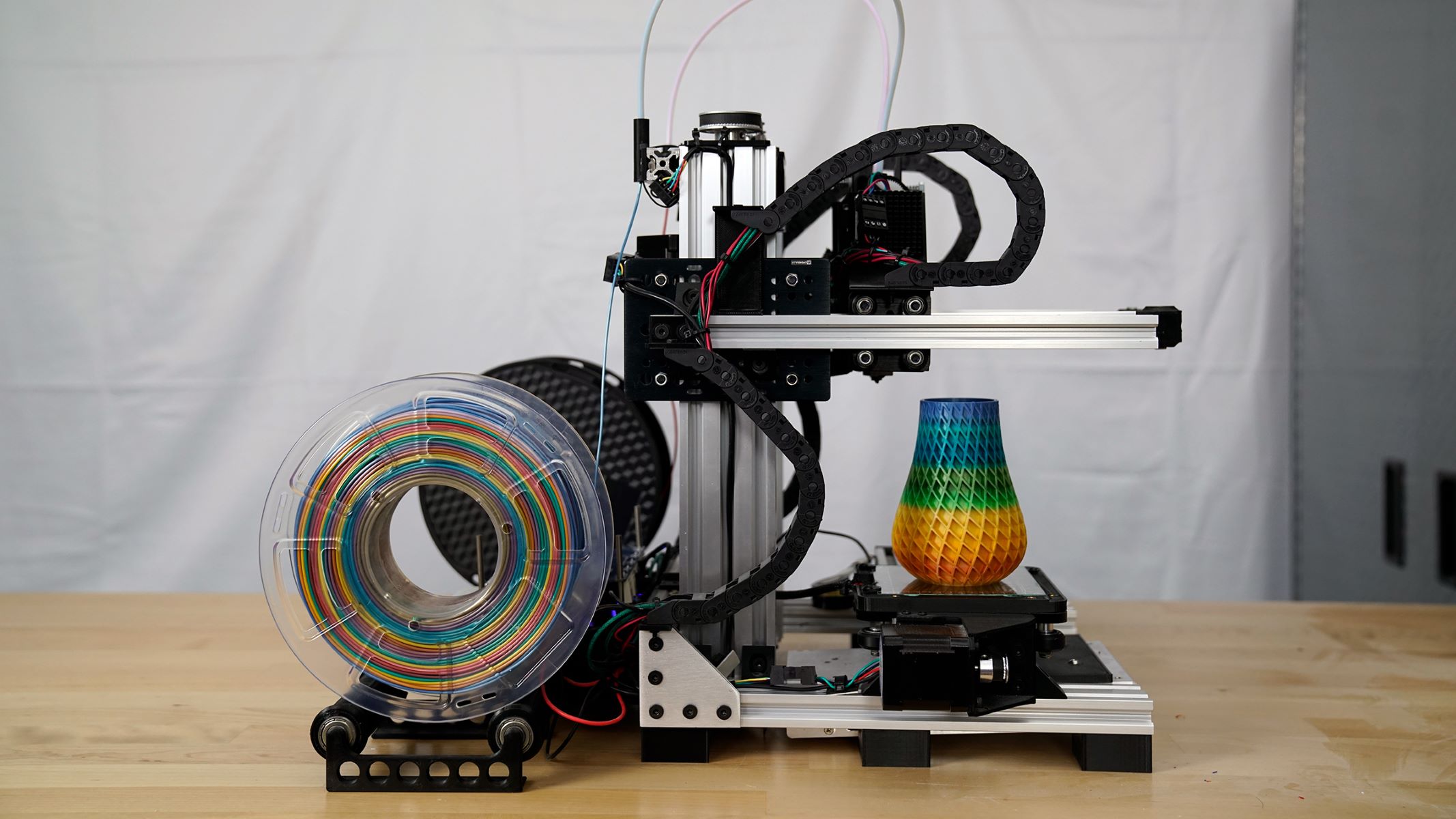

Welcome to the fascinating world of 3D printing! In this article, we will delve into the crucial aspect of determining the nozzle size for your 3D printer. Whether you are a beginner or an experienced enthusiast, understanding the significance of nozzle size and its impact on the 3D printing process is essential for achieving optimal results.

The nozzle size plays a pivotal role in determining the level of detail, speed, and overall quality of your 3D prints. By selecting the appropriate nozzle size, you can fine-tune various aspects of the printing process, including layer resolution, material flow, and printing time. In this comprehensive guide, we will explore the importance of nozzle size in 3D printing, factors to consider when determining the ideal nozzle size, and methods for accurately determining the most suitable nozzle size for your specific printing needs.

Whether you are aiming to create intricate prototypes, functional parts, or artistic designs, the nozzle size serves as a critical factor in achieving your desired outcomes. Join us as we embark on a journey to unravel the mysteries of nozzle size in 3D printing, empowering you to make informed decisions and elevate your 3D printing endeavors to new heights.

**

Key Takeaways:

- Nozzle size in 3D printing impacts print quality, speed, and versatility. Understanding factors and methods for determination empowers optimal 3D printing outcomes.

- Experimentation, iterative testing, and community insights enhance understanding of nozzle size’s influence on 3D printing, enabling tailored approaches for exceptional results.

Read more: How To Unclog A 3D Printer Nozzle

Importance of Nozzle Size in 3D Printing

**

The nozzle size in 3D printing holds immense significance, influencing various aspects of the printing process and the characteristics of the final printed objects. Understanding the importance of nozzle size is fundamental to achieving the desired level of precision, strength, and surface finish in 3D prints.

1. Layer Resolution: The nozzle size directly impacts the layer resolution of 3D prints. A smaller nozzle diameter allows for finer details and smoother surfaces, resulting in higher-resolution prints. Conversely, a larger nozzle diameter facilitates faster printing but may sacrifice intricate details and surface quality.

2. Printing Speed: Nozzle size affects the printing speed, with larger nozzles enabling faster extrusion rates. This is particularly advantageous for producing larger prototypes or functional parts where speed is prioritized over intricate details.

3. Material Flow: The nozzle size influences the flow of printing material, impacting the overall strength and structural integrity of the printed objects. Selecting the appropriate nozzle size is crucial for ensuring optimal material flow and adhesion between layers, thereby enhancing the mechanical properties of the printed parts.

4. Support Structures: When printing complex geometries or overhanging features, the nozzle size plays a role in determining the efficiency and stability of support structures. A smaller nozzle diameter allows for more precise support generation, minimizing the need for post-processing and reducing material waste.

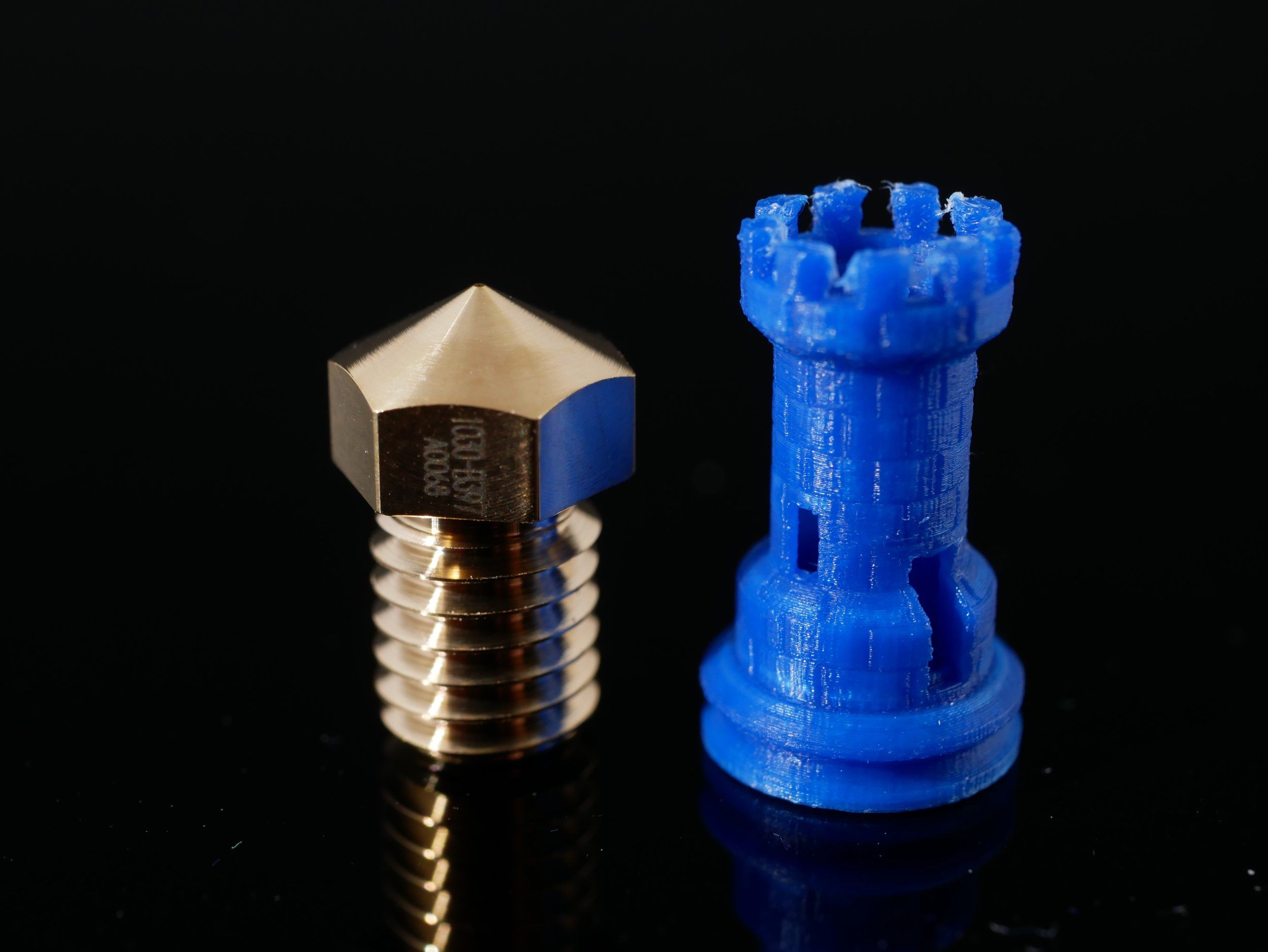

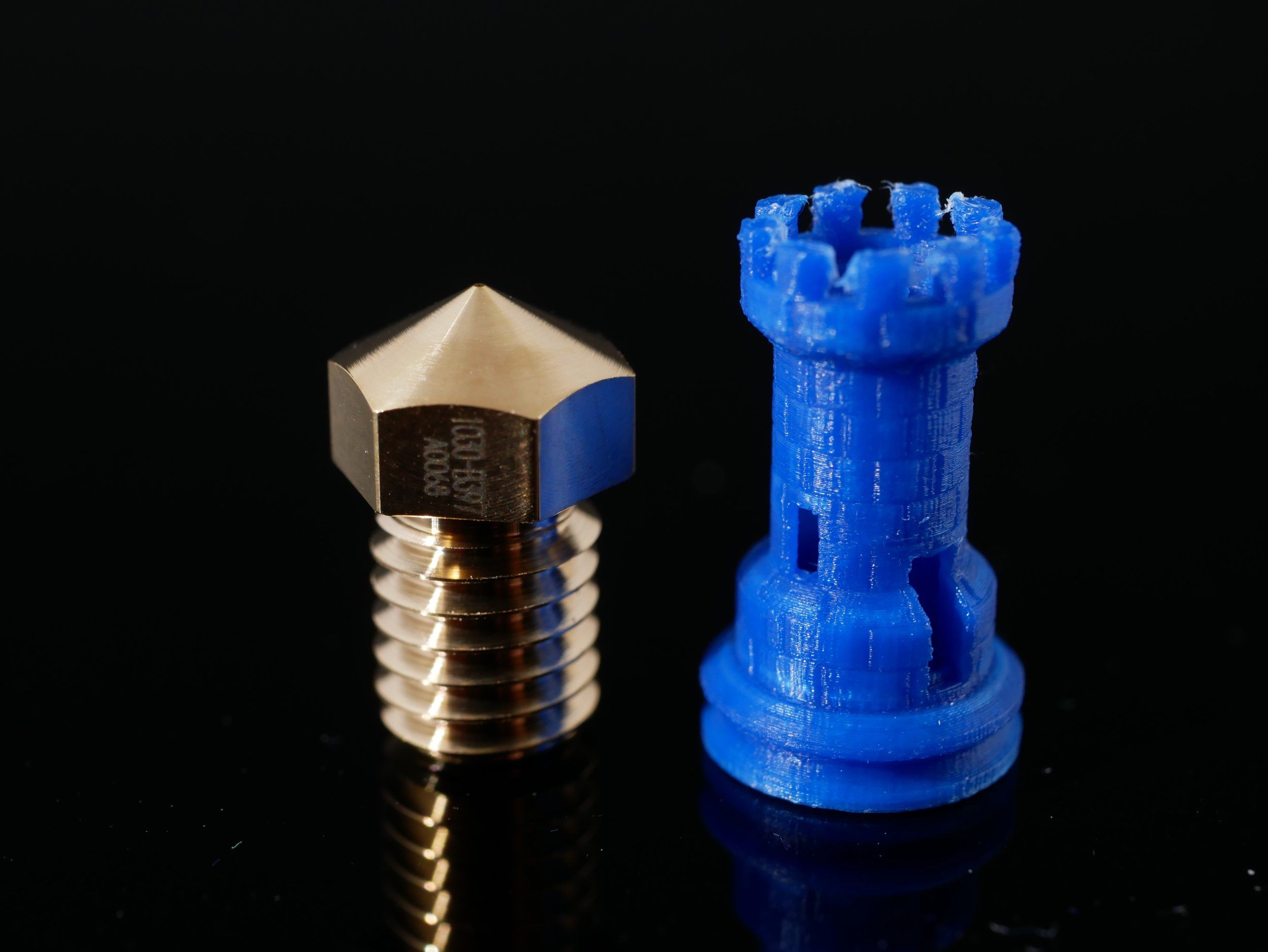

5. Versatility: By having a range of nozzle sizes at your disposal, you can enhance the versatility of your 3D printer, catering to a diverse array of printing requirements. Whether you seek to produce intricate miniatures or robust functional prototypes, the ability to switch between different nozzle sizes empowers you to adapt to varying project demands.

Choosing the right nozzle size is akin to wielding a painter’s brush, where each stroke influences the intricacy and visual appeal of the artwork. With a keen understanding of the importance of nozzle size in 3D printing, you can harness this knowledge to optimize the quality, efficiency, and versatility of your 3D printing endeavors.

**

Factors to Consider When Determining Nozzle Size

**

When determining the ideal nozzle size for your 3D printing projects, several crucial factors come into play, each influencing the printing process and the characteristics of the final prints. By carefully considering these factors, you can make informed decisions that align with your specific printing requirements and desired outcomes.

1. Printing Resolution: The level of detail and intricacy required in your prints is a primary consideration when selecting a nozzle size. For high-resolution prints with fine details, a smaller nozzle diameter, such as 0.4mm or lower, is preferable. On the other hand, larger nozzle diameters, such as 0.6mm or above, are suitable for faster printing of prototypes or parts where intricate details are not a priority.

2. Material Compatibility: Different printing materials have varying flow characteristics and viscosities, which can influence the choice of nozzle size. For instance, fine materials like PLA and ABS may work well with small nozzle sizes, while materials with additives or composite properties might require larger nozzles to facilitate smooth extrusion.

3. Printing Speed: The urgency of your printing projects and the desired printing speed are important factors to consider. Larger nozzle sizes enable faster extrusion rates, making them suitable for rapid prototyping or producing larger parts within a shorter timeframe. Conversely, smaller nozzle sizes are ideal for achieving higher-resolution prints with intricate details, albeit at a slower pace.

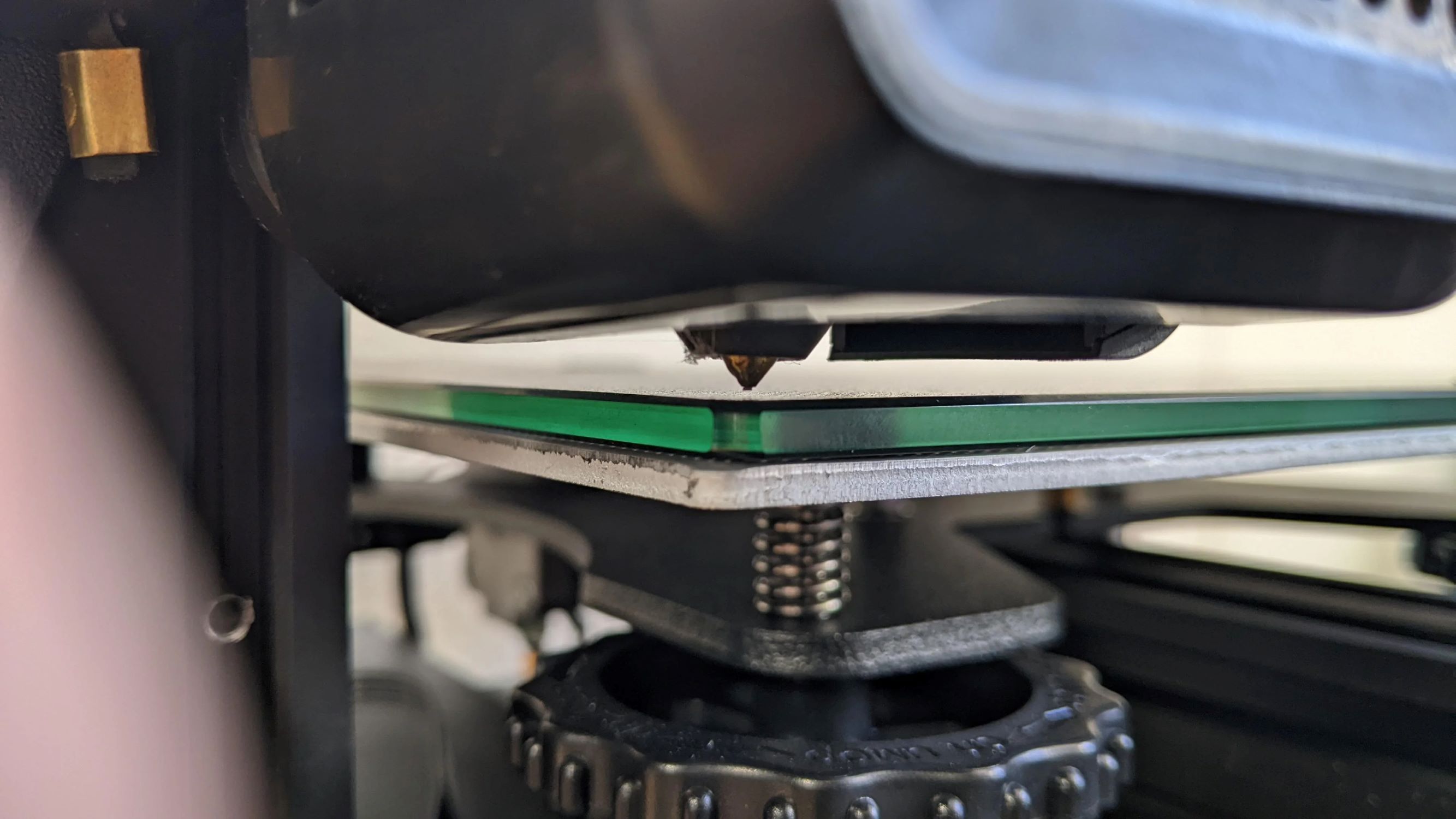

4. Layer Height and Adhesion: Nozzle size impacts the layer height and adhesion between printed layers. Smaller nozzles allow for thinner layers, resulting in smoother surfaces and improved layer adhesion. This is particularly beneficial for creating aesthetically pleasing prints with minimal visible layer lines. Larger nozzles, while sacrificing some surface quality, excel in producing robust prints with faster layer deposition.

5. Print Volume and Structural Integrity: Consider the size and structural requirements of your prints. For large-volume prints or parts necessitating enhanced strength, larger nozzle sizes can expedite the printing process while ensuring adequate material deposition for robust and durable objects.

By carefully evaluating these factors and understanding their implications on the 3D printing process, you can effectively determine the most suitable nozzle size for each printing project, optimizing the balance between speed, detail, and material compatibility. Through this thoughtful approach, you can harness the full potential of your 3D printer and achieve exceptional results across diverse applications.

**

When determining the nozzle size for your 3D printer, consider the level of detail and speed you want. Smaller nozzles produce finer details but take longer, while larger nozzles are faster but have less detail.

Methods for Determining Nozzle Size

**

When it comes to determining the most suitable nozzle size for your 3D printing endeavors, several methods can be employed to guide your decision-making process. By leveraging these methods, you can gain valuable insights into the ideal nozzle size that aligns with your specific printing requirements and project objectives.

1. Manufacturer Recommendations: Many 3D printer manufacturers provide recommendations and guidelines regarding the compatible nozzle sizes for their printers. By referring to the manufacturer’s specifications and documentation, you can gain valuable insights into the recommended nozzle sizes based on the printer’s capabilities and intended applications.

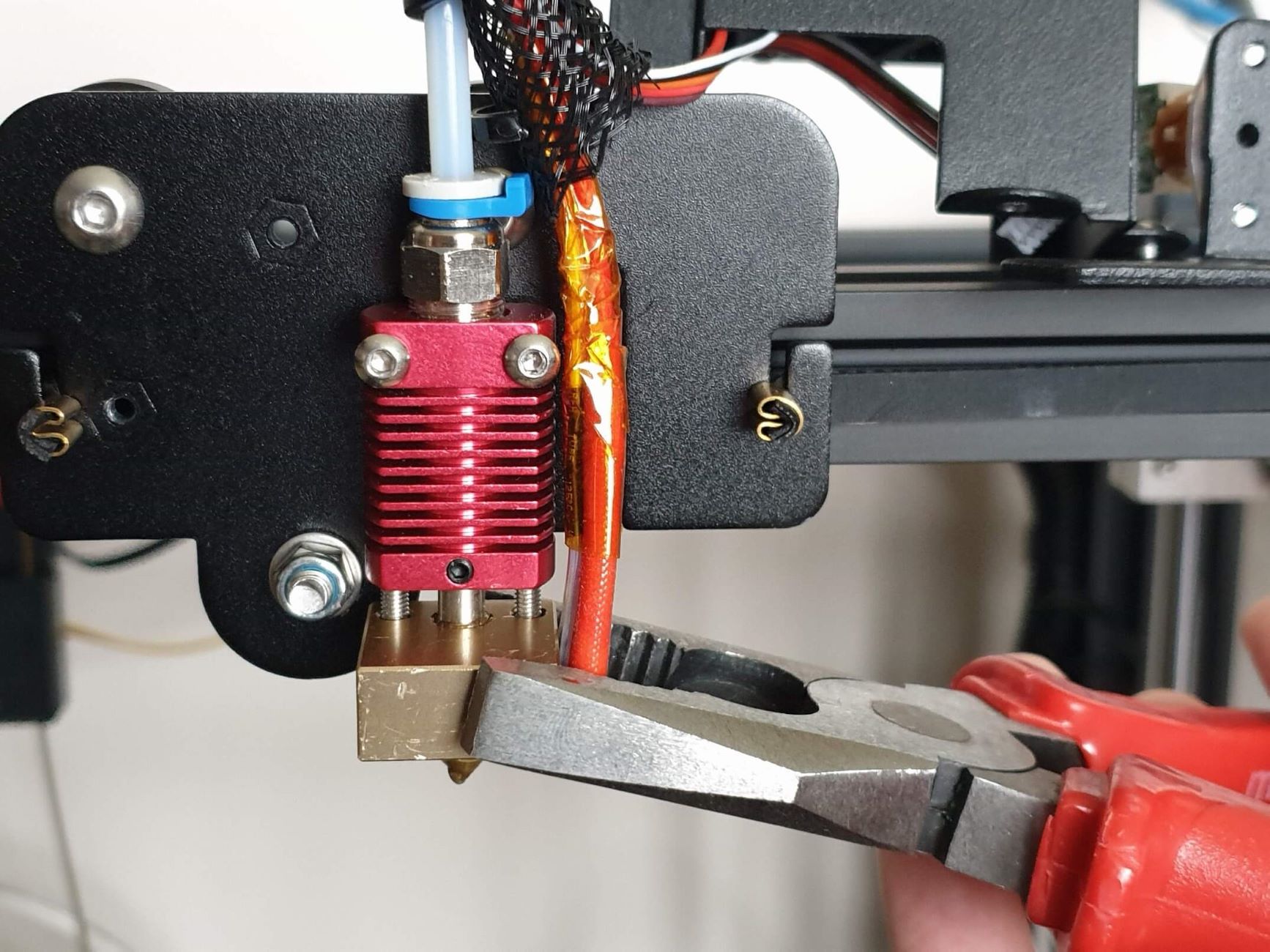

2. Material Compatibility Testing: Conducting material compatibility tests with different nozzle sizes can offer practical insights into the optimal nozzle size for specific printing materials. By printing test models or sample objects using varying nozzle diameters and observing the print quality and material flow characteristics, you can determine the most suitable nozzle size for each material type.

3. Calibration Prints: Utilizing calibration prints, such as single-wall cubes or intricate test models, with different nozzle sizes allows for direct comparisons of print quality, dimensional accuracy, and surface finish. These calibration prints serve as valuable benchmarks for evaluating the performance of different nozzle sizes and fine-tuning the printing parameters to achieve optimal results.

4. Iterative Testing and Adjustment: Engaging in iterative testing and adjustment processes, where you systematically vary the nozzle size and printing parameters for specific projects, enables you to refine your understanding of how different nozzle sizes impact the final prints. Through this iterative approach, you can identify the optimal balance between printing speed, detail, and material flow for each application.

5. Community Feedback and Resources: Leveraging the collective knowledge and experiences of the 3D printing community through forums, online resources, and user groups can provide valuable insights into nozzle size selection. Engaging in discussions, seeking advice, and exploring case studies from fellow enthusiasts and experts can broaden your perspective and inform your decisions regarding nozzle size determination.

By employing these methods in combination or individually, you can navigate the process of determining the most suitable nozzle size with confidence and precision. Embracing a systematic and experimental approach, complemented by insights from the 3D printing community and manufacturer recommendations, empowers you to optimize the performance of your 3D printer across a diverse range of printing projects.

**

Conclusion

**

As we conclude our exploration of determining nozzle size in 3D printing, it becomes evident that the nozzle size serves as a critical determinant of print quality, speed, and versatility. By carefully considering the factors that influence nozzle size selection and leveraging various methods for determination, you can optimize the performance of your 3D printer and elevate the outcomes of your printing projects.

The intricate dance between nozzle size, material compatibility, printing speed, and structural requirements necessitates a thoughtful and informed approach to nozzle size determination. Whether you aim to produce finely detailed miniatures, robust functional prototypes, or artistic creations, the nozzle size plays a pivotal role in shaping the characteristics of your prints.

By embracing experimentation, iterative testing, and community insights, you can expand your understanding of how different nozzle sizes influence the 3D printing process, allowing you to tailor your approach to each unique project. The ability to adapt and refine your nozzle size selection based on specific printing requirements empowers you to achieve exceptional results across diverse applications, unlocking the full potential of your 3D printer.

As you embark on your 3D printing journey, remember that the nozzle size is not merely a technical specification, but a tool for creativity, precision, and innovation. Whether you are driven by engineering challenges, artistic pursuits, or functional prototyping, the nozzle size stands as a versatile instrument in your quest to transform digital designs into tangible, three-dimensional realities.

In the ever-evolving landscape of 3D printing, where innovation and creativity intersect with technology, the knowledge and insights gained from understanding nozzle size determination will propel you towards new frontiers of possibility and achievement. Embrace the art and science of nozzle size selection, and let it serve as a catalyst for realizing your vision and materializing your imagination in the form of intricately crafted 3D prints.

With a deepened understanding of the importance of nozzle size, the factors influencing its selection, and the methods for determination, you are poised to embark on a journey of boundless creativity and technical mastery in the realm of 3D printing. Let the nozzle size be your ally, guiding you towards the realization of your boldest and most intricate creations.

Frequently Asked Questions about How To Determine Nozzle Size In 3D Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Determine Nozzle Size In 3D Printer”