Home>Technology>Smart Home Devices>When To Replace A 3D Printer Nozzle

Smart Home Devices

When To Replace A 3D Printer Nozzle

Published: January 19, 2024

Learn when it's time to replace your 3D printer nozzle for optimal performance. Get expert tips on maintaining your smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Welcome to the world of 3D printing, where creativity and innovation converge to bring your ideas to life. As a 3D printing enthusiast, you understand the importance of maintaining your printer to ensure the highest quality output. One crucial component of a 3D printer is the nozzle, which plays a pivotal role in the printing process. Over time, nozzles can wear out, affecting the overall print quality and accuracy. In this article, we will explore the signs that indicate a worn-out nozzle, the factors to consider before replacing it, and a step-by-step guide on how to replace a 3D printer nozzle. By the end of this article, you will have a comprehensive understanding of when and how to replace your 3D printer nozzle, empowering you to optimize your printing experience and produce exceptional prints. Let's dive in!

**

Key Takeaways:

- Recognize signs like decreased print quality, extrusion issues, and clogging as indicators for replacing a 3D printer nozzle. Stay vigilant to maintain print quality and precision.

- Consider factors like print material compatibility, precision requirements, and long-term maintenance before replacing a 3D printer nozzle. Make informed decisions to enhance your 3D printing experience.

Read more: How To Clean A Clogged 3D Printer Nozzle

Signs of a Worn Out Nozzle

**

Recognizing the signs of a worn-out 3D printer nozzle is essential for maintaining the quality and precision of your prints. Here are some common indicators that your nozzle may need replacement:

- Decreased Print Quality: One of the most noticeable signs of a worn-out nozzle is a decline in print quality. You may observe inconsistent extrusion, rough surfaces, or visible defects in the printed objects. These imperfections can detract from the overall aesthetics and functionality of your prints, indicating the need for a new nozzle.

- Extrusion Issues: A worn-out nozzle often leads to extrusion problems, such as under-extrusion or over-extrusion. Under-extrusion results in gaps and incomplete layers, while over-extrusion causes excessive material deposition, leading to blobbing and oozing. These issues can compromise the structural integrity of the prints and necessitate a thorough nozzle assessment.

- Clogging and Jamming: Nozzle clogging and jamming are common issues associated with wear and tear. Accumulated debris, filament residue, or partial blockages can impede the smooth flow of filament through the nozzle, resulting in print interruptions and irregular flow patterns. If you frequently encounter clogs or jams, it’s a strong indication that the nozzle requires attention.

- Print Artifacts: When inspecting your prints, watch out for artifacts such as stringing, zits, or wisps of filament between printed features. These imperfections often stem from nozzle-related issues, signaling the need for a thorough nozzle examination and potential replacement.

- Increased Nozzle Diameter: Over time, the nozzle orifice can widen due to abrasive filament materials or prolonged use. This enlargement alters the extrusion flow and compromises the precision of the prints. If you notice a significant increase in the nozzle diameter, it’s advisable to consider replacing the nozzle to restore optimal printing performance.

By staying vigilant for these signs, you can proactively address nozzle-related issues and uphold the excellence of your 3D prints. Now that we’ve identified the common indicators of a worn-out nozzle, let’s delve into the factors to consider before replacing it.

**

Factors to Consider Before Replacing

**

Before proceeding with the replacement of your 3D printer nozzle, it’s important to consider several factors that can impact the decision-making process. By evaluating these aspects, you can make an informed choice and ensure that the replacement aligns with your printing needs and goals. Here are the key factors to consider:

- Print Material Compatibility: Different print materials have varying levels of abrasiveness and flow characteristics, which can affect the longevity of a nozzle. Consider the type of filament you predominantly use and assess its impact on the nozzle’s wear. For abrasive filaments like carbon fiber or metallic composites, a hardened steel or specialized nozzle may be more suitable for prolonged durability.

- Print Precision Requirements: Evaluate the precision and detail level required for your prints. Nozzle diameter directly influences print resolution, with smaller nozzles enabling finer details and intricate features. Before replacing the nozzle, determine the ideal diameter based on your printing objectives and the desired balance between speed and precision.

- Printer Compatibility: Not all nozzles are universally compatible with every 3D printer model. Verify the compatibility of the replacement nozzle with your specific printer make and model to ensure seamless integration and optimal performance. Additionally, consider any additional hardware or firmware adjustments that may be necessary for the new nozzle.

- Printing Speed and Throughput: The choice of nozzle diameter can impact printing speed and material extrusion rates. Larger nozzles facilitate faster printing but may sacrifice fine detail, while smaller nozzles offer enhanced precision at the expense of increased print times. Assess your printing speed requirements and balance them with the desired print quality before selecting a replacement nozzle.

- Cost and Long-Term Maintenance: Replacement nozzles come in various materials and price points, each with its own maintenance considerations. Factor in the long-term maintenance requirements and costs associated with different nozzle materials, especially if you anticipate high-volume printing or extended usage. Consider the overall value and durability of the replacement nozzle in relation to its initial cost.

By carefully evaluating these factors, you can make an informed decision regarding the replacement of your 3D printer nozzle, ensuring that the new nozzle aligns with your printing requirements and enhances the overall printing experience. With these considerations in mind, let’s proceed to explore the step-by-step process of replacing a 3D printer nozzle.

**

Replace your 3D printer nozzle if you notice poor print quality, clogs, or inconsistent extrusion. A worn or damaged nozzle can affect the accuracy and quality of your prints.

How to Replace a 3D Printer Nozzle

**

Replacing a 3D printer nozzle is a straightforward process that, when done with care and precision, can significantly improve the quality and reliability of your prints. Follow these step-by-step instructions to seamlessly replace the nozzle and optimize your 3D printing experience:

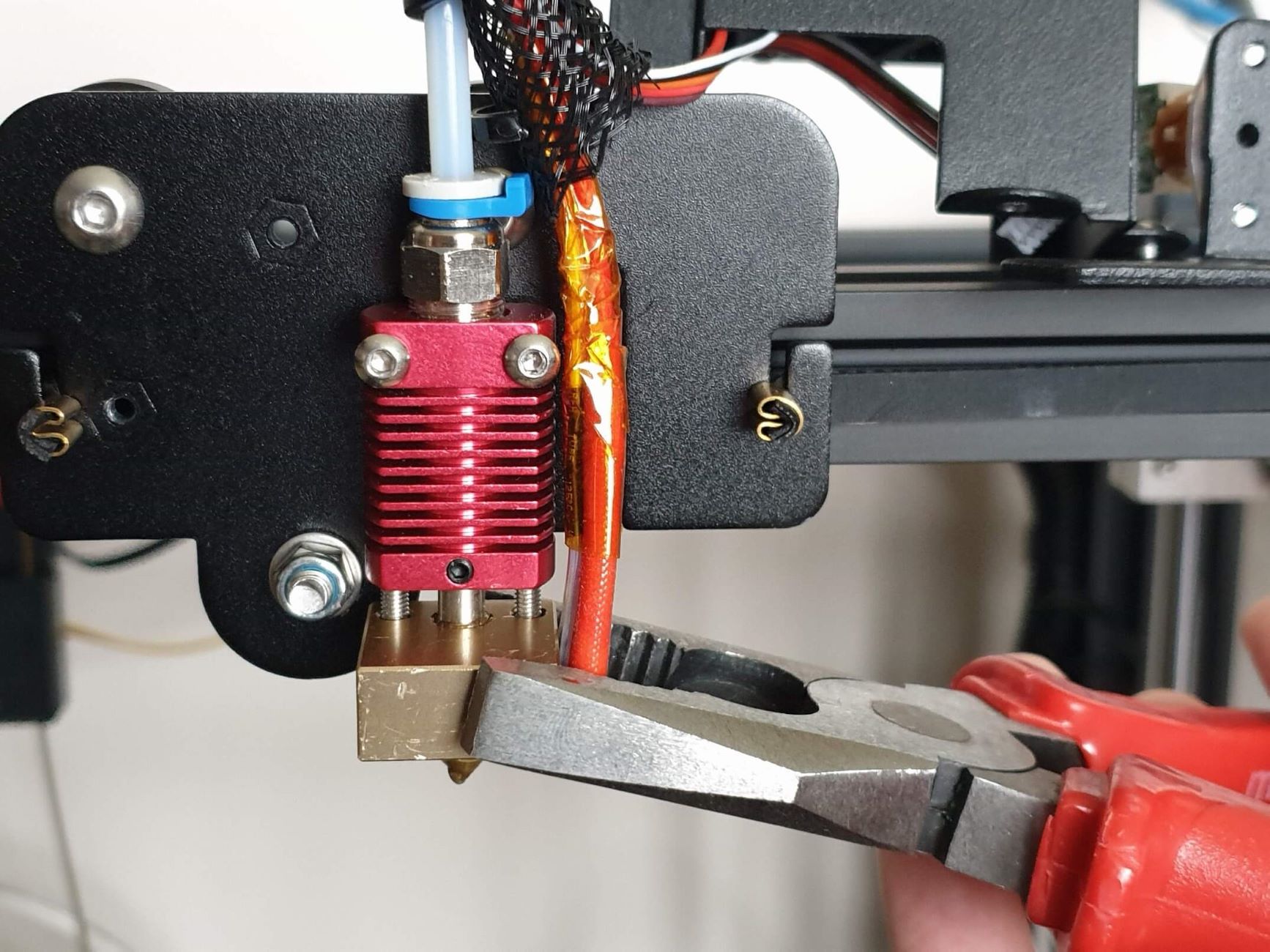

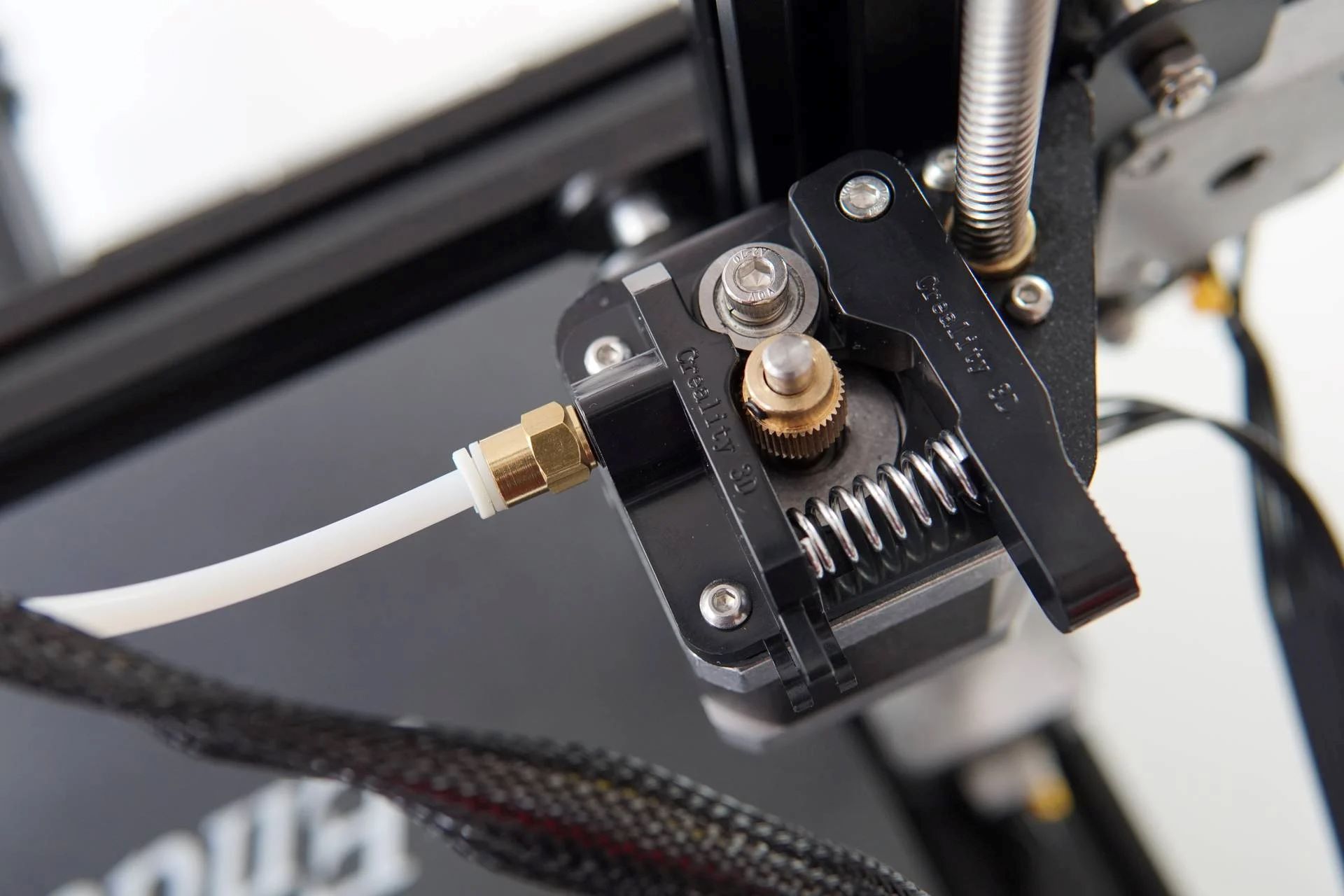

- Gather the Necessary Tools: Before beginning the replacement process, ensure that you have the required tools readily available. These typically include a nozzle wrench or socket, heat-resistant gloves, a cleaning needle or filament, and any additional tools specific to your printer model.

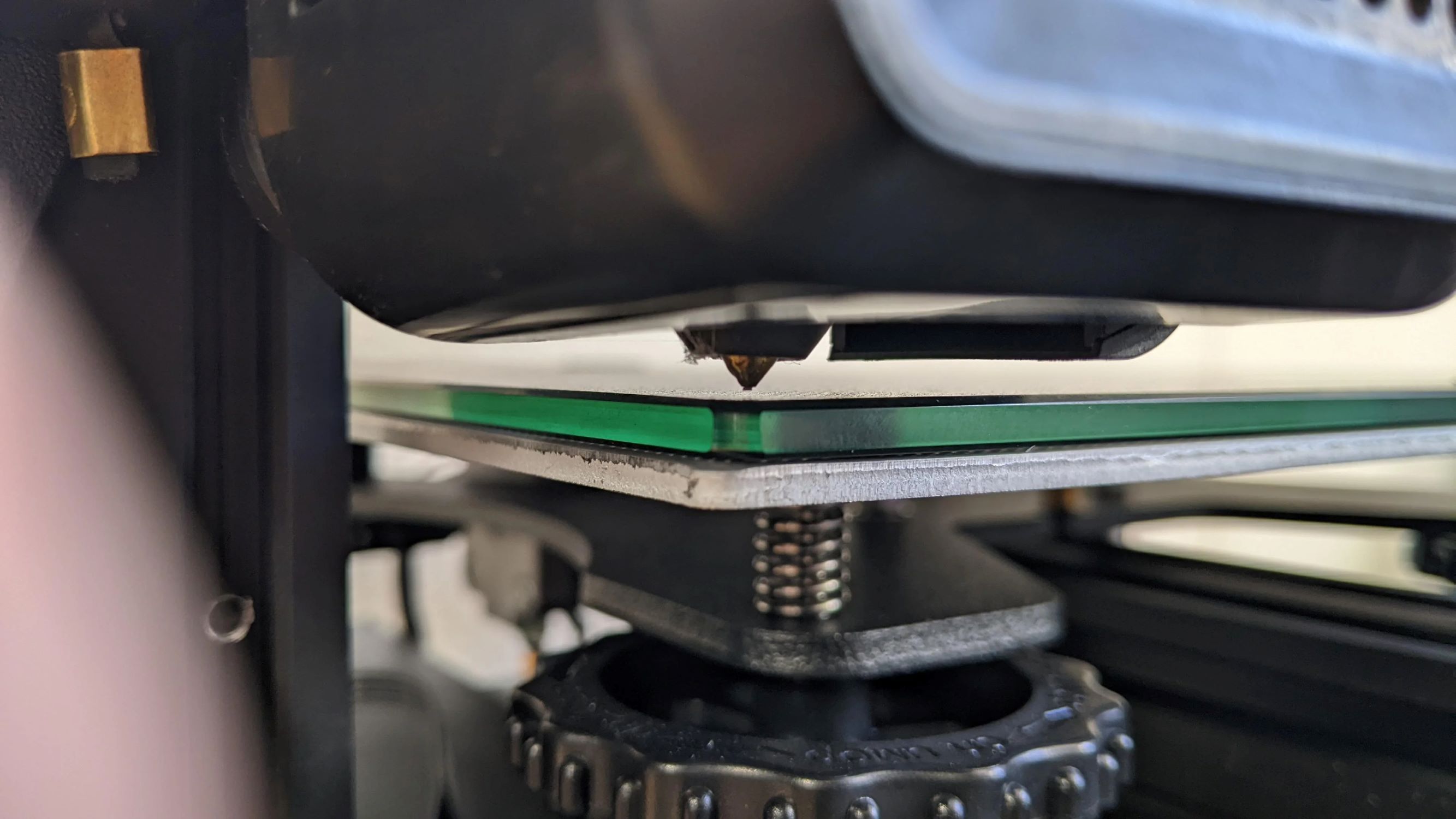

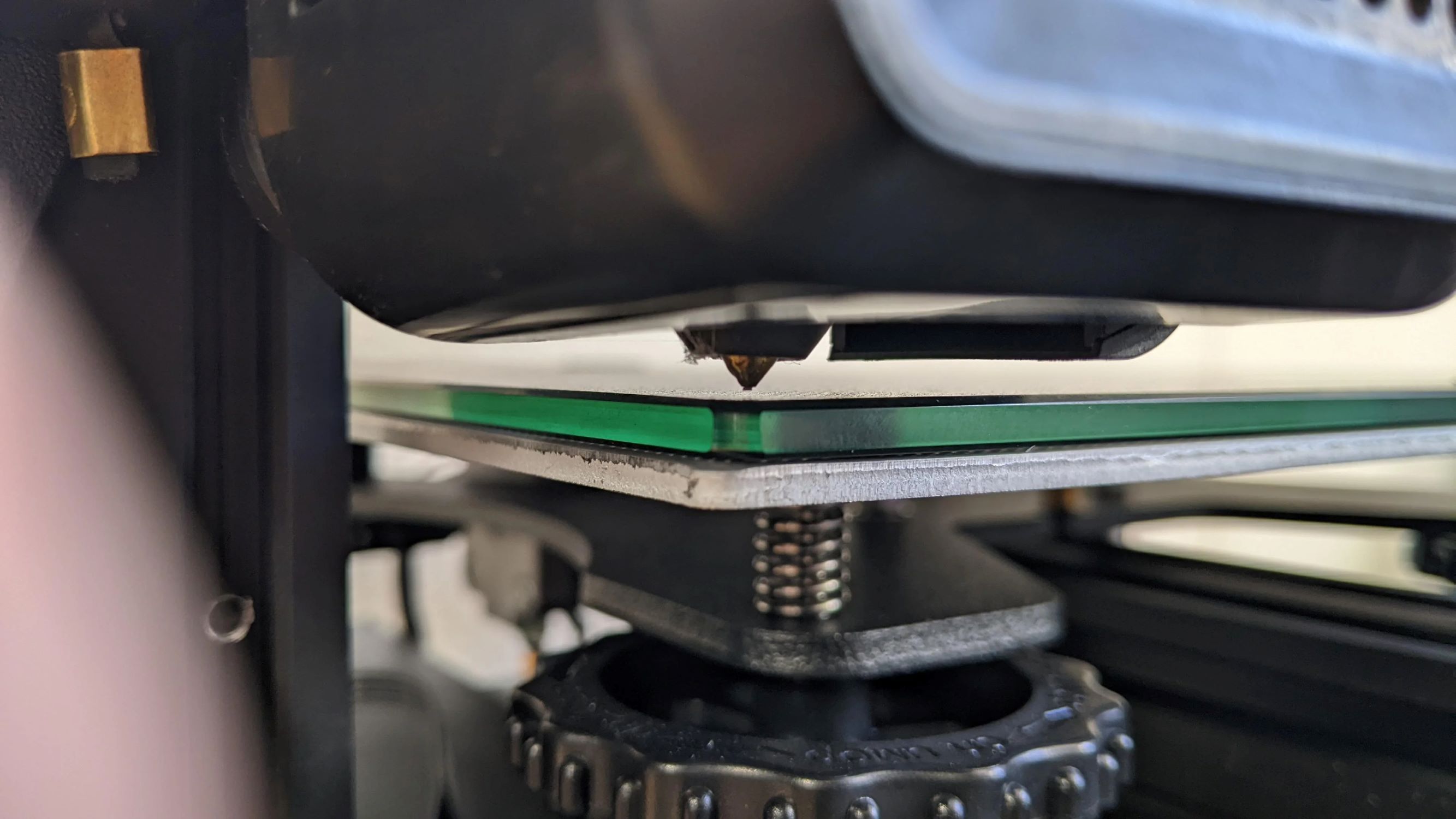

- Prepare the Printer: Power on the 3D printer and allow it to reach the operating temperature suitable for removing the existing nozzle. Heating the nozzle facilitates the softening and removal of any filament residue, making the replacement process smoother.

- Secure the Hotend: Using the appropriate tools, carefully secure the hotend to prevent any accidental damage or movement during the replacement. Exercise caution when handling the hotend to avoid burns or injuries.

- Remove the Existing Nozzle: With the hotend secured, use the nozzle wrench or socket to carefully unscrew and remove the worn-out nozzle from the hotend assembly. Take care to handle the hot nozzle with heat-resistant gloves to avoid burns.

- Clean the Hotend: Once the old nozzle is removed, use a cleaning needle or filament to clear any residual material or debris from the hotend and ensure a clean, unobstructed pathway for the new nozzle installation.

- Install the New Nozzle: Take the new 3D printer nozzle and carefully screw it into place on the hotend assembly, ensuring a snug and secure fit. Exercise caution to avoid over-tightening, which can lead to damage or misalignment.

- Perform Nozzle Calibration: After installing the new nozzle, recalibrate the printer settings, including nozzle diameter and printing parameters, to accommodate the replacement. This step is crucial for achieving accurate extrusion and print quality with the new nozzle.

- Test the Printer: Once the replacement is complete and the printer is recalibrated, conduct a test print to assess the performance and quality of the new nozzle. Observe the print closely for any irregularities or improvements compared to previous prints.

- Maintenance and Monitoring: Regularly monitor the performance of the new nozzle and implement routine maintenance practices to prolong its lifespan and sustain optimal print quality. This may include periodic cleaning, filament material considerations, and adherence to manufacturer recommendations.

By following these steps and exercising caution throughout the process, you can seamlessly replace the 3D printer nozzle and elevate the quality of your prints. Now that you’re equipped with the knowledge of nozzle replacement, let’s conclude our exploration of this essential aspect of 3D printing.

**

Conclusion

**

Congratulations on gaining a comprehensive understanding of when and how to replace a 3D printer nozzle. By recognizing the signs of a worn-out nozzle, considering essential factors before replacement, and mastering the step-by-step process of nozzle replacement, you are well-equipped to optimize your 3D printing experience and achieve exceptional print quality.

As you embark on your 3D printing journey, remember to stay attuned to the performance of your nozzle and address any signs of wear or deterioration promptly. Proactive maintenance and thoughtful consideration of print material compatibility, precision requirements, printer compatibility, printing speed, and long-term maintenance can contribute to sustained printing excellence.

Whether you’re pursuing intricate prototypes, functional parts, or artistic creations, the condition of your nozzle plays a pivotal role in realizing your vision with precision and reliability. Embrace the process of nozzle replacement as an opportunity to fine-tune your printing setup and elevate the quality of your prints.

As technology continues to evolve, the world of 3D printing holds endless possibilities for innovation and creativity. By staying informed and proactive in maintaining your 3D printer, you are poised to unleash your imagination and bring your designs to life with unparalleled accuracy and finesse.

With your newfound knowledge, embark on your 3D printing endeavors with confidence, knowing that you have the expertise to recognize the signs of a worn-out nozzle, evaluate replacement factors, and execute a seamless nozzle replacement process. Your dedication to mastering the nuances of 3D printing will undoubtedly yield remarkable results and propel your creative endeavors to new heights.

Here’s to a future filled with impeccable prints, boundless creativity, and the transformative power of 3D printing. Happy printing!

Frequently Asked Questions about When To Replace A 3D Printer Nozzle

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “When To Replace A 3D Printer Nozzle”