Home>Articles>How To Build A Kegerator Out Of A Refrigerator

Articles

How To Build A Kegerator Out Of A Refrigerator

Modified: February 19, 2024

Discover step-by-step articles on how to transform a regular refrigerator into a kegerator, making it easy to enjoy draft beer at home.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Are you a beer enthusiast who wants to enjoy draft beer from the comfort of your own home? Look no further – building a kegerator out of a refrigerator is the perfect solution. Not only will it save you money on buying individual bottles or cans, but it will also give you the freedom to pour a fresh pint anytime you want.

Building a kegerator may seem like a daunting task, but with the right materials and a bit of know-how, it can be a fun and rewarding DIY project. In this guide, we will take you through the step-by-step process of converting a regular refrigerator into a fully functioning kegerator.

But before we dive into the nitty-gritty details, let’s talk about what exactly a kegerator is. Essentially, a kegerator is a refrigerator that is specifically designed to hold and dispense kegs of beer. It consists of a refrigeration unit, a tap system, and a CO2 system.

By housing a keg of your favorite beer and connecting it to the tap system, you can pour a perfectly chilled and carbonated pint anytime you please. Not only will you have access to a variety of beers at your fingertips, but you can also impress your friends and family with your DIY skills.

So, if you’re ready to embark on the journey of building your own kegerator, let’s get started with the required materials.

Key Takeaways:

- Building a kegerator out of a refrigerator is a fun and rewarding DIY project that allows beer enthusiasts to enjoy draft beer at home, save money, and impress friends with their DIY skills.

- Selecting the right refrigerator, preparing it for keg installation, and fine-tuning the tap and CO2 systems are crucial steps in creating a personalized kegerator that delivers the perfect pour every time.

Read more: How To Build A Kegerator

Required Materials

Before you can begin the process of building your kegerator, it’s important to gather all the necessary materials. Here’s a list of what you’ll need:

1. Refrigerator: The first and most important item on your list is a refrigerator. Look for a model with enough space to accommodate the size of keg you plan to use. Ideally, choose a refrigerator with a top-freezer configuration, as it provides more room for the keg and tap system.

2. Keg: Next, you’ll need a keg of your favorite beer. Kegs come in various sizes, including quarter-barrels, half-barrels, and mini-kegs. Consider the amount of beer you plan to consume, as well as the storage space in your refrigerator, when selecting the size of the keg.

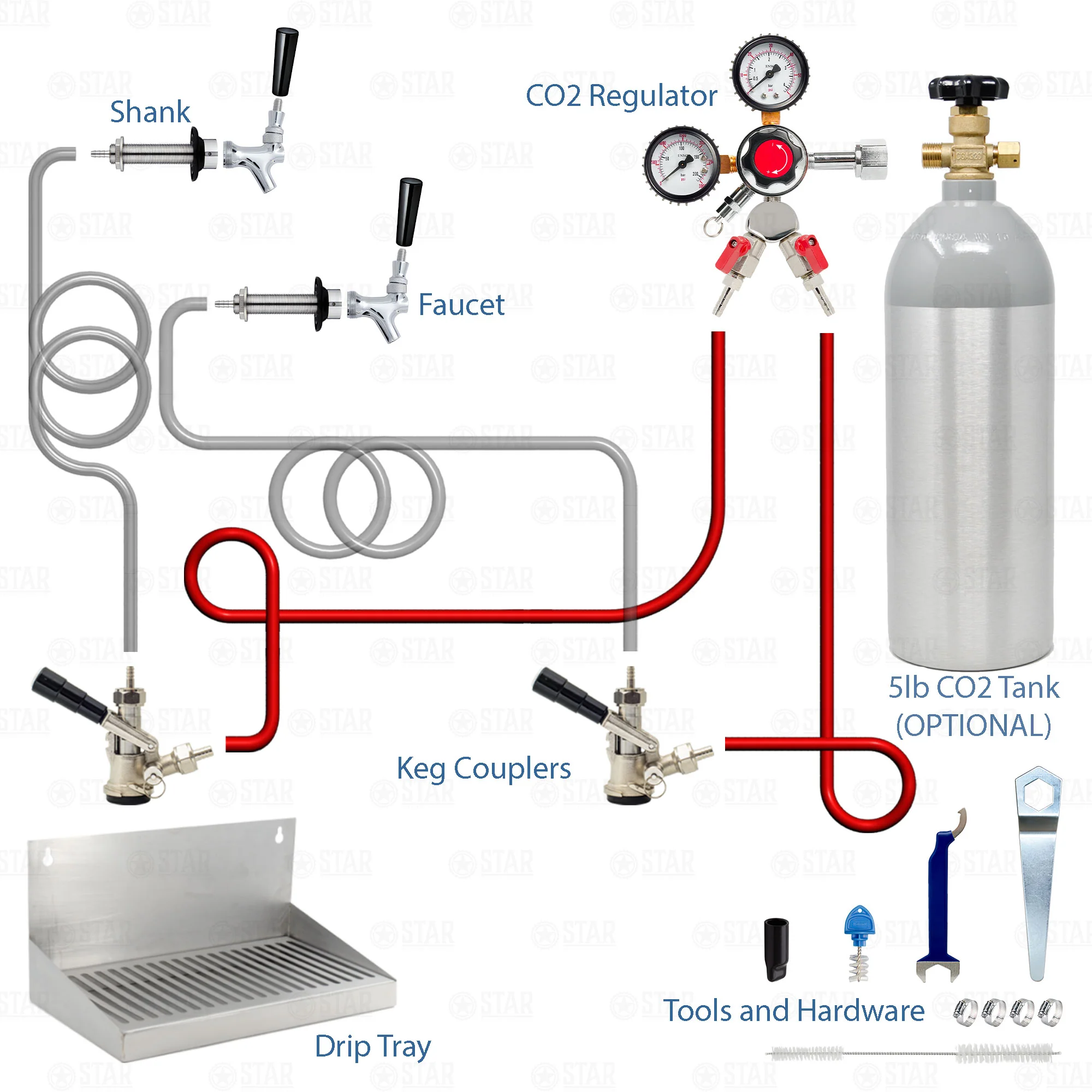

3. Conversion Kit: To transform your refrigerator into a kegerator, you’ll need a conversion kit. This typically includes a CO2 tank, regulator, gas lines, beer lines, faucets, shanks, and fittings. You can purchase a pre-assembled kit or buy the components individually.

4. CO2 System: A crucial component of your kegerator is the CO2 system. This provides the pressure necessary to dispense the beer from the keg. Make sure to choose a CO2 tank that fits inside your refrigerator and consider getting a dual-gauge regulator for precise control.

5. Tap System: The tap system allows you to pour beer directly from the keg. It usually includes a faucet, shank, and handle. Choose a tap system that matches your kegerator setup and personal preference. There are various styles, sizes, and materials available.

6. Cleaning Supplies: Keeping your kegerator clean is vital to maintaining the quality of your beer. Be sure to have cleaning brushes, a keg cleaning kit, and a cleaner specifically designed for beer lines. Regular cleaning will prevent contamination and off-flavors.

7. Taps and Accessories: To enhance your kegerator setup, consider adding additional accessories such as drip trays, tap handles, tap locks, and keg couplers. These accessories not only add functionality but also give your kegerator a polished and professional appearance.

Once you have all the required materials, you’re ready to start converting your refrigerator into a kegerator. In the next section, we’ll guide you through the process of selecting the right refrigerator.

Step 1: Selecting the Right Refrigerator

The first step in building your kegerator is selecting the right refrigerator to serve as the base for your project. Here are some key considerations to keep in mind:

1. Size and Capacity: Consider the size of the keg you plan to use and ensure that the refrigerator has enough space to accommodate it. Measure the available space inside the refrigerator to ensure a proper fit.

2. Top-Freezer Configuration: Opt for a refrigerator with a top-freezer configuration as it provides more interior space for the keg and tap system. This layout allows for easy access to the keg without interfering with the cooling mechanism.

3. Temperature Control: Look for a refrigerator with adjustable temperature controls. Beer needs to be stored at specific temperatures, typically between 36-44°F (2-7°C), to maintain its quality and freshness.

4. Energy Efficiency: Consider the energy efficiency of the refrigerator. Look for models with an Energy Star label to ensure that it consumes less power, reducing your energy costs in the long run.

5. Door Type: Decide whether you want a refrigerator with a single door or French doors. Single-door refrigerators are a popular choice as they provide a larger area to install the tap system, while French door models offer a more aesthetically pleasing appearance.

6. Accessibility: Consider the location of the refrigerator in your home and ensure it is easily accessible. You will need to connect the CO2 system and access the keg, so choose a spot that is convenient for maintenance and refilling.

7. Budget: Set a budget for your kegerator project and find a refrigerator that fits within your price range. Look for sales and discounts, as well as refurbished or used options, to save money on your purchase.

Once you have a refrigerator that meets these criteria, it’s time to move on to the next step – preparing the refrigerator for keg installation.

Step 2: Preparing the Refrigerator

Now that you have selected the right refrigerator, it’s time to prepare it for the keg installation. Here’s what you need to do:

1. Empty and Clean: Start by removing all the food and beverages from the refrigerator. Clean the interior thoroughly with a mild detergent and warm water. Make sure to rinse and dry it completely to avoid any residue or odors.

2. Remove Shelves and Drawers: Take out any shelves, drawers, or racks that may obstruct the keg or tap system installation. This will create enough space to fit the keg comfortably and attach the necessary components.

3. Drill Holes: To accommodate the beer lines and CO2 line, you will need to drill holes in the refrigerator. Choose a suitable location for the holes, preferably at the top or side of the refrigerator where they won’t interfere with the cooling mechanism.

4. Install Beer Tower: If you opt for a beer tower instead of a tap on the front door, you will need to install it. Place the beer tower on top of the refrigerator and use the provided hardware to secure it in place. Make sure it is aligned properly and stable.

5. Attach Drip Tray: If you want to prevent any spills or drips, attach a drip tray below the tap or beer tower. This will collect any excess liquid and keep your kegerator area clean and tidy.

6. Replace Shelves and Drawers: After completing the necessary modifications, put back the shelves, drawers, or racks that were removed. Ensure that they fit securely and properly within the refrigerator.

7. Check the Seal: It’s important to check the door seal of the refrigerator to ensure it is working properly. A tight seal will maintain the temperature inside and prevent any air leakage that could affect the cooling efficiency.

By preparing your refrigerator properly, you are one step closer to enjoying fresh, draft beer at home. In the next step, we will guide you through the process of installing the tap system for your kegerator.

Step 3: Installing the Tap System

Now that your refrigerator is prepared, it’s time to install the tap system. Follow these steps to ensure a proper installation:

1. Positioning the Faucet: Decide where you want to install the faucet on the refrigerator door or beer tower. Mark the spot and use a drill to create a hole of the appropriate size. Make sure the hole is slightly smaller than the diameter of the shank to ensure a snug fit.

2. Inserting the Shank: Take the shank and insert it into the hole from the front of the refrigerator or beer tower. Secure it in place using the provided washer and nut on the inside of the refrigerator door.

3. Attaching the Faucet: Once the shank is in place, attach the faucet to the end of the shank. Use a wrench to tighten it, ensuring a watertight seal.

4. Connecting the Beer Line: Connect one end of the beer line to the liquid-out port on the keg coupler. Attach the other end to the nipple on the back of the faucet. Secure it with a clamp to prevent any leaks.

5. Testing for Leaks: Turn on the CO2 tank and check for any leaks in the system. Apply a soapy solution to all the connections and look for bubbles. If you notice any leaks, tighten the connections further until they are sealed.

6. Purging the Beer Line: To ensure that there is no air left in the beer line, open the faucet and let the beer flow through for a few seconds. This will purge the line of any air and ensure a smooth pour.

7. Cleaning the Faucet: Before using your new tap system, it’s important to clean the faucet thoroughly. Use a faucet brush and a cleaning solution designed for beer lines to remove any bacteria or residue.

Once the tap system is properly installed and tested, you are ready to move on to the next step – connecting the CO2 system for carbonation and dispensing the beer.

When converting a refrigerator into a kegerator, make sure to measure the interior space to ensure it can accommodate the keg and CO2 tank. Also, consider adding a temperature controller for better beer storage.

Read more: How To Build A Freezer Kegerator

Step 4: Connecting the CO2 System

In order to carbonate and dispense the beer from your keg, you need to connect the CO2 system. Follow these steps to ensure a successful connection:

1. Attach the Regulator: Start by attaching the regulator to the CO2 tank. Tighten the nut on the regulator by hand and then give it an extra turn with a wrench to ensure a secure connection.

2. Connect the Gas Line: Take one end of the gas line and attach it to the barb fitting on the regulator. Secure it in place using a clamp.

3. Connect the Other End: The other end of the gas line should be connected to the gas-in port on the keg coupler. Ensure a tight connection to prevent any leaks.

4. Adjust the Pressure: Adjust the pressure on the regulator according to the recommended PSI (pounds per square inch) for the specific beer you are dispensing. This information can usually be found on the keg or the brewery’s website.

5. Check for Leaks: As with the tap system, it’s important to check for any leaks in the CO2 system. Apply a soapy solution to all the connections and look for bubbles. If you notice any leaks, tighten the connections further until they are sealed.

6. Carbonation: Once the CO2 system is connected, the carbonation process begins. Allow the keg to sit at the recommended temperature for a desired period of time to carbonate the beer. This can range from a few days to a couple of weeks, depending on the style of beer.

7. Adjust and Fine-Tune: During the carbonation process, periodically check and adjust the pressure on the regulator if necessary. This will help you achieve the desired carbonation level for your beer.

Connecting the CO2 system is a crucial step in the kegerator building process. Once the beer is properly carbonated, you are ready to move on to the next step – testing and adjusting your kegerator.

Step 5: Testing and Adjusting the Kegerator

After connecting the CO2 system and allowing the beer to carbonate, it’s time to test and adjust your kegerator. Follow these steps to ensure optimal performance:

1. Check the Temperature: Before testing, verify that the temperature inside the kegerator is within the recommended range for the style of beer you’re dispensing. Use a thermometer to measure the temperature and make any necessary adjustments to the refrigerator settings.

2. Pour a Test Pint: Prepare a glass and open the faucet to pour a test pint. Observe the flow and consistency of the beer. If the beer pours too foamy or flat, you may need to adjust the pressure on the regulator.

3. Adjust the Pressure: To achieve the desired beer carbonation and pour, you may need to adjust the pressure on the regulator. Incrementally increase or decrease the pressure and pour another test pint until you achieve the desired results.

4. Monitor the Carbonation: During this testing phase, pay attention to the carbonation level of the beer. If the beer tastes undercarbonated or overcarbonated, adjust the pressure accordingly. Remember, it may take several adjustments to achieve the perfect carbonation.

5. Fine-Tune the Temperature: If necessary, make further adjustments to the refrigerator temperature settings to attain the ideal serving temperature for your beer. This will ensure optimal taste and quality with each pour.

6. Clean the Lines: Regularly clean the beer lines and faucet to prevent any buildup of bacteria or residue. Follow the manufacturer’s instructions for cleaning solutions and use a line cleaning kit to maintain the quality of your beer.

7. Enjoy the Perfect Pour: Once you are satisfied with the pouring process and the taste of your beer, it’s time to enjoy the fruits of your labor. Share your kegerator with friends and family, and revel in the joy of having a perfectly poured pint of draft beer at home.

Remember, each beer may have slightly different carbonation requirements, so it’s important to test and adjust accordingly. With time and practice, you will become a kegerator expert and be able to consistently pour delicious beers from your very own setup.

In the next step, we will discuss some final touches and optional enhancements that you can add to elevate your kegerator experience.

Step 6: Final Touches and Optional Enhancements

With your kegerator fully functional, it’s time to add some final touches and optional enhancements to customize your setup. Here are a few ideas to consider:

1. Drip Tray Upgrade: Upgrade your drip tray to a larger size or one with a drain system. This will help catch any spills or drips and keep your kegerator area clean and tidy.

2. Tap Handles: Personalize your kegerator by adding unique tap handles. There are a wide variety of tap handles available, including custom-made options, sports team logos, and novelty designs. Choose handles that reflect your personal style and interests.

3. Kegerator Cover: Protect your kegerator and make it blend seamlessly with your home decor by investing in a kegerator cover. These covers are available in various colors and materials and can help enhance the overall appearance of your setup.

4. LED Lighting: Consider adding LED lighting inside your kegerator for a cool and eye-catching effect. These lights can be programmed to change colors and create a vibrant atmosphere while serving your favorite beers.

5. Chalkboard or Whiteboard Panels: Transform the front or sides of your kegerator into a chalkboard or whiteboard surface. This allows you to write down the beer on tap, create custom labels, or leave messages for your guests.

6. Kegerator Tower Cooler: To ensure your beer stays cool in the tap tower, especially in warmer climates, add a kegerator tower cooler. This device sits inside the tower and keeps the lines and faucet chilled, preventing any foaming issues.

7. Digital Temperature Controller: Upgrade your kegerator’s temperature control system with a digital temperature controller. This will provide precise control over the cooling system, ensuring your beer is always served at the perfect temperature.

Remember, these enhancements are optional and can be added based on your preferences and budget. They can elevate your kegerator experience and create a more enjoyable space for yourself and your guests.

After implementing these final touches, take a step back and admire your creation. You have successfully built a functional and personalized kegerator out of a refrigerator. Now it’s time to sit back, relax, and savor the taste of draft beer from the comfort of your own home.

In the final section, we will summarize the key points and conclude our guide on building a kegerator.

Conclusion

Congratulations! You have successfully built your very own kegerator out of a refrigerator. By following the step-by-step process outlined in this guide, you have transformed a regular fridge into a fully functional system for dispensing draft beer.

Throughout the journey, you have learned the importance of selecting the right refrigerator, preparing it for keg installation, and installing the tap and CO2 systems. You have also discovered the significance of testing, adjusting, and maintaining your kegerator to ensure the perfect pour every time.

Building a kegerator allows you to enjoy the experience of having fresh draft beer on tap at all times. It not only saves you money in the long run but also gives you the freedom to explore a wide range of beers from the comfort of your own home.

Remember to clean your kegerator regularly to maintain the quality of your beer and to fine-tune the temperature and pressure settings to suit the specific beer you are dispensing. These small adjustments will ensure that you can enjoy a perfectly carbonated and chilled pint of beer with every pour.

Additionally, don’t be afraid to add your personal touch to your kegerator with optional enhancements like tap handles, LED lighting, or a kegerator cover. These additions can make your setup even more unique and reflect your personal style.

Now that you have completed your kegerator, it’s time to sit back, relax, and enjoy the fruits of your labor. Invite your friends and family over for a gathering and impress them with your very own homemade draft beer.

Building a kegerator is not only a practical endeavor but also a creative and rewarding one. It allows you to unleash your DIY skills and create a custom setup that adds a touch of sophistication to your home.

Cheers to your new kegerator and the countless memories and enjoyable moments it will bring. So, raise your glass and toast to your success as you indulge in the pleasure of having draft beer on demand – all thanks to your own ingenuity and craftsmanship!

Frequently Asked Questions about How To Build A Kegerator Out Of A Refrigerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Build A Kegerator Out Of A Refrigerator”