Articles

How To Use A Circular Saw

Modified: March 1, 2024

Learn how to effectively use a circular saw with our comprehensive articles. Discover valuable tips and techniques for precision cutting and woodworking projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

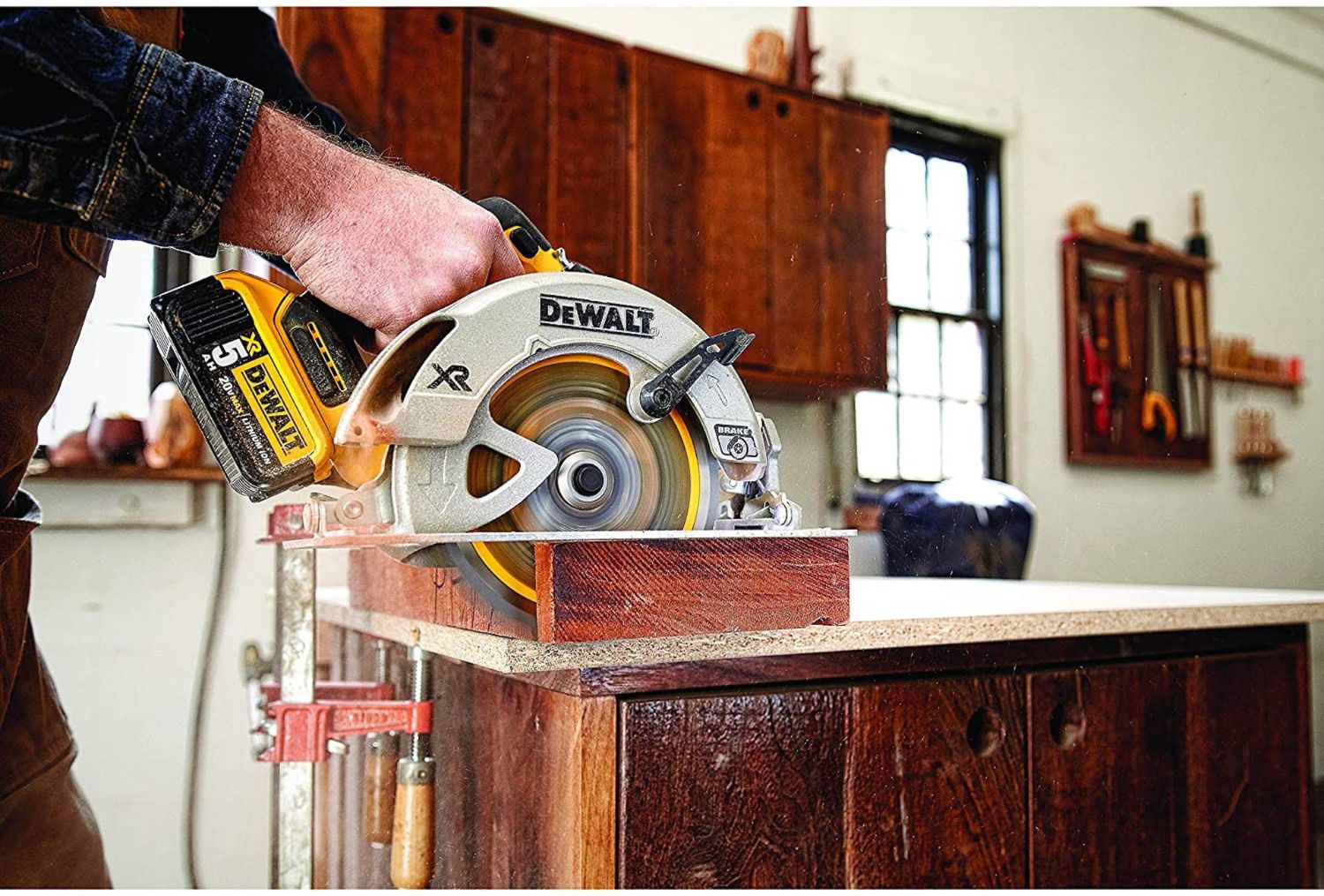

Using a circular saw is a fundamental skill that every DIY enthusiast or professional carpenter should master. This versatile power tool is perfect for making straight cuts in a variety of materials, including wood, plastic, and metal. Whether you’re building a bookshelf, renovating your home, or working on a small woodworking project, a circular saw is an essential tool to have in your arsenal.

In this comprehensive guide, we will walk you through everything you need to know about using a circular saw. From understanding the safety precautions to selecting the right saw for your needs, adjusting the blade depth and bevel angle, and mastering different cutting techniques, we’ve got you covered.

Before we dive into the practical aspects of using a circular saw, it’s important to prioritize safety. Circular saws are powerful tools that can cause serious injuries if not handled correctly. So, let’s start by discussing some safety precautions that should always be followed.

Key Takeaways:

- Safety is paramount when using a circular saw. Prioritize protective gear, secure work areas, and follow manufacturer guidelines to minimize the risk of accidents and ensure a safe working environment.

- Mastering advanced techniques such as creating dado cuts, making rabbet joints, and using a guide rail can enhance the versatility of a circular saw, providing added precision and efficiency for woodworking projects.

Read more: How To Use Ryobi Circular Saw

Safety Precautions

When using a circular saw, safety should always be your top priority. Follow these precautions to minimize the risk of accidents and ensure a safe working environment:

- Read the instruction manual: Familiarize yourself with the manufacturer’s guidelines and follow them meticulously. Understand the specific safety features, recommended operating procedures, and maintenance requirements.

- Protective gear: Always wear proper safety gear, including safety glasses or goggles to protect your eyes from debris, a dust mask to prevent inhalation of sawdust, and ear protection to reduce noise exposure.

- Secure work area: Make sure your work area is clean, well-lit, and free from any potential hazards. Keep the floor clear of tripping hazards and ensure there is ample space to maneuver the saw.

- Firm grip and stance: Maintain a firm grip on the saw with both hands and stand in a stable position with your feet shoulder-width apart. Avoid overreaching or standing on unstable surfaces.

- Keep distractions away: Remove any distractions, such as children or pets, from the work area to ensure your full attention is on the task at hand. Avoid using a circular saw when you are tired or under the influence of any substances.

- Inspect the saw: Before each use, carefully inspect the saw, power cord, and blade for any damage or defects. Make sure all guards and safety features are properly functioning.

- Use the appropriate blade: Ensure that the blade you are using is suitable for the material you intend to cut. Using the wrong blade can increase the risk of accidents and damage the saw or workpiece.

- Disconnect power: Always unplug the saw from the power source or remove the battery before making any adjustments or blade changes. This prevents accidental starts and keeps you safe during maintenance.

- Proper blade guarding: The circular saw should always be equipped with a blade guard. Ensure that the guard is in place and functioning properly. Never disable or remove the guard during operation.

- Controlled cuts: Take your time and maintain a steady pace while cutting. Do not force the saw or let it veer off the cutting line. Use a guide or straight edge to ensure precise and accurate cuts.

By following these safety guidelines and staying vigilant, you can significantly reduce the risk of accidents while using a circular saw. Remember, your safety is paramount, so never compromise on safety precautions.

Selecting the Right Circular Saw

Choosing the right circular saw for your needs is crucial to ensure optimal performance and efficiency. With a variety of options available in the market, consider the following factors before making a purchase:

- Power source: Circular saws are available in two main types: corded and cordless. Corded saws are more powerful and provide constant power supply, making them suitable for heavy-duty projects. Cordless saws, on the other hand, offer portability and convenience but may have limited battery life.

- Blade size: Circular saws come in different blade sizes, typically ranging from 6.5 to 10 inches. The blade size determines the depth of cut the saw can achieve. Select a blade size based on the maximum thickness of the material you will be cutting.

- Motor power: The motor power of a circular saw is measured in amps for corded saws and volts for cordless saws. Higher amp or voltage ratings indicate more power, enabling the saw to handle tougher materials and provide smoother cuts. Consider your intended usage and the types of materials you frequently work with.

- Bevel capacity: Check the bevel capacity of the saw, which indicates the maximum angle at which the blade can be tilted. A higher bevel capacity allows for more versatile cutting, especially when working on angled cuts or beveled edges.

- Ergonomics and weight: Consider the weight and ergonomics of the circular saw, as it can impact comfort and maneuverability during prolonged use. Look for a saw with an ergonomic handle design and a reasonable weight for optimal control.

- Additional features: Some circular saws come with extra features such as laser guides for improved accuracy, LED lights for better visibility, and dust extraction ports to minimize dust accumulation. These features can enhance your cutting experience but may come at an additional cost.

- Brand and reputation: Research the reputation of different brands and read customer reviews to gauge the reliability and quality of the circular saw. Look for trusted brands that offer good warranty coverage and customer support.

Take your time to assess your specific requirements and budget before investing in a circular saw. Remember to prioritize durability, performance, and safety features to ensure your saw meets your expectations and withstands the demands of your projects.

Understanding the Parts of a Circular Saw

Before you start using a circular saw, it’s important to familiarize yourself with its various parts. Understanding the anatomy of the saw will not only help you operate it safely but also enable you to make necessary adjustments and perform maintenance tasks effectively. Here are the key parts of a circular saw:

- Blade: The circular saw blade is the most essential component. It consists of a sharp circular disc with teeth that do the cutting. The type and size of the blade will depend on the material you are cutting.

- Motor: Located behind the blade, the motor is responsible for rotating the blade at high speeds, enabling it to cut through the material. The motor can be either corded or cordless, depending on the type of saw you have.

- Base Plate or Shoe: Also known as the shoe or sole plate, the base plate is the flat metal or aluminum surface that rests on the material being cut. It provides stability and acts as a guide for the saw.

- Depth Adjustment Lever: The depth adjustment lever allows you to control the cutting depth of the blade. By adjusting this lever, you can determine how deep the blade will cut into the material.

- Bevel Adjustment: The bevel adjustment mechanism enables you to tilt the base plate or shoe at an angle. This allows you to make bevel cuts, where the blade cuts at an angle other than 90 degrees.

- Handle: The handle is designed to provide a comfortable grip while operating the saw. It allows you to control the movement of the saw and maintain stability during cutting.

- Trigger Switch: Located on the handle, the trigger switch is used to start and stop the saw. It is a safety feature that requires you to press and hold the switch for the saw to operate.

- Blade Guard: The blade guard is a safety feature designed to cover the blade when it is not in use. It retracts when you push the saw into the material and automatically covers the blade when you release the trigger.

- Power Cord or Battery: For corded circular saws, the power cord supplies electricity to the motor. Cordless circular saws use a rechargeable battery pack to power the motor.

Understanding these parts and their functions will help you operate the circular saw with confidence and precision. Always refer to the instruction manual provided by the manufacturer for specific information about your saw’s parts and how to use them correctly.

Setting Up the Circular Saw

Before you can start using a circular saw, you need to properly set it up for optimal performance and safety. Follow these steps to ensure your saw is ready to go:

- Choose the Right Blade: Select a blade that is appropriate for the material you will be cutting. Different blades are designed for different materials, such as wood, metal, or plastic. Make sure the blade is sharp and in good condition before installing it.

- Secure the Workpiece: Place your workpiece on a stable and secure surface, such as a workbench or sawhorses. Ensure that the material is firmly clamped or held down to prevent movement during cutting. This will help you achieve clean and accurate cuts.

- Adjust the Blade Depth: Set the blade depth according to the thickness of the material. The depth adjustment lever on the saw allows you to control how deep the blade will cut. Align the blade so that it extends about 1/4 inch below the bottom surface of the workpiece.

- Set the Bevel Angle: If you need to make bevel cuts, adjust the bevel angle on the saw. Loosen the bevel adjustment lever and tilt the base plate or shoe to the desired angle. Lock it into place by tightening the lever.

- Check the Alignment: Before you start cutting, make sure the blade is aligned properly with the cutting line. You can use a straight edge or a guide to ensure accuracy. Adjust the saw’s position if needed to ensure it follows the desired cutting path.

- Connect the Power: If you are using a corded circular saw, plug it into a power outlet. If you have a cordless saw, make sure the battery is fully charged and securely attached to the saw.

- Ensure Safety Features are Functional: Check that the blade guard is in good working condition and moves freely over the blade as you push the saw forward. Confirm that the trigger switch operates smoothly and releases immediately when you let go.

- Test the Saw: Before you start cutting your project material, make a test cut on a scrap piece of the same material. This allows you to ensure that the saw is set up correctly, the blade is spinning smoothly, and the cut is accurate.

By following these steps, you can confidently set up your circular saw for precise and safe cutting. Take the time to double-check all the adjustments and safety features before you begin any cutting tasks.

Read more: How To Store Circular Saw

Adjusting the Blade Depth and Bevel Angle

Properly adjusting the blade depth and bevel angle on your circular saw is crucial for achieving accurate and efficient cuts. Here’s how you can adjust these settings:

Blade Depth Adjustment

To adjust the depth of the blade, follow these steps:

- Unplug the saw or remove the battery for cordless models.

- Locate the depth adjustment lever on the saw, typically located near the blade housing or on the side of the motor.

- Loosen the depth adjustment lever by turning it counterclockwise.

- Align the base plate or shoe with the depth markings on the saw to indicate the desired cutting depth.

- Tighten the depth adjustment lever by turning it clockwise to secure the desired depth setting.

- Check the blade depth by holding the saw over the workpiece without turning it on. The blade should extend about 1/4 inch below the material’s surface for most cutting applications. Adjust as needed.

Remember, setting the correct blade depth ensures efficient cutting while minimizing the risk of the blade cutting too deeply and causing damage or kickback. Always adjust the blade depth before starting any cutting tasks.

Bevel Angle Adjustment

If you need to make bevel cuts at an angle other than 90 degrees, you can adjust the bevel angle on your circular saw. Follow these steps:

- Unplug the saw or remove the battery for cordless models.

- Locate the bevel adjustment lever or knob on the saw. It is usually located at the front or rear of the base plate.

- Loosen the bevel adjustment lever or knob to release the shoe’s locked position.

- Tilt the base plate or shoe to the desired bevel angle. Use the markings on the shoe or a protractor as a guide.

- Lock the base plate into position by tightening the bevel adjustment lever or knob.

- Double-check the bevel angle by placing a square or angle gauge against the base plate and blade. Ensure the angle is accurate before making any cuts.

Remember to adjust the bevel angle carefully and securely lock it into place. This will ensure that your bevel cuts are precise and consistent.

By mastering the techniques to adjust the blade depth and bevel angle, you’ll have greater control over your cuts and be able to tackle a wider range of projects with your circular saw.

Using the Circular Saw

Once you have set up your circular saw and adjusted the necessary settings, it’s time to start using it! Here’s a step-by-step guide on how to use a circular saw:

- Secure your workpiece: Ensure that the material you are cutting is properly secured to prevent it from moving during the cutting process. Use clamps or other suitable methods to hold it firmly in place.

- Position the saw: Hold the circular saw with both hands, with one hand on the handle and the other on the auxiliary handle, if provided. Position yourself in a stable and balanced stance.

- Align the blade: Align the blade of the saw with the cutting line on the workpiece. Make sure the blade is positioned to cut along the desired path.

- Activate the saw: Press the trigger switch to start the blade rotation. Allow the blade to reach full speed before proceeding with the cut.

- Begin the cut: Gently push the saw forward, allowing the blade to make contact with the workpiece. Apply steady and even pressure while maintaining control over the saw.

- Move at a consistent pace: Keep the saw moving at a steady pace, avoiding any sudden stops or hesitation. This will help ensure clean and smooth cuts.

- Follow the cutting line: Keep your focus on the cutting line and guide the saw along it. Use both hands to maintain control and stability throughout the cutting process.

- Complete the cut: Once you have reached the end of the cut, release the trigger switch to stop the blade rotation. Allow the blade to come to a complete stop before removing it from the workpiece.

- Inspect the cut: After making the cut, examine the end result to ensure it meets your requirements. Make any necessary adjustments or additional cuts if needed.

Remember to always prioritize safety and follow the recommended precautions while using a circular saw. Take breaks as needed and keep the work area clean and organized to minimize distractions and potential hazards.

With practice, you will gain confidence and proficiency in using a circular saw, allowing you to efficiently complete various cutting tasks and achieve professional results.

Read more: How To Store A Circular Saw

Making Straight Cuts

Making straight cuts with a circular saw requires precision and careful execution. Follow these steps to ensure clean and accurate straight cuts:

- Measure and mark: Use a measuring tape and a straightedge to measure and mark the desired length of the cut on your workpiece. Double-check your measurements to ensure accuracy.

- Align the saw: Position the circular saw so that the blade is aligned with the cutting line you marked on the workpiece. Take care to align the blade and the line precisely.

- Prepare for the cut: Adjust the depth of the blade, ensuring that it extends slightly below the bottom surface of the workpiece. This will prevent any tear-out or splintering.

- Start the cut: Hold the saw firmly with both hands, one on the handle and the other on the auxiliary handle if available. Position the base plate firmly on the workpiece, ensuring stability. Activate the saw and let the blade reach its full speed.

- Guide the cut: Slowly push the saw forward along the cutting line, maintaining a steady pace. Use both hands to guide the saw smoothly and follow the line accurately. Keep your focus on the line as you proceed with the cut.

- Maintain control: Apply even pressure on the saw throughout the cut, keeping it stable and preventing it from veering off the line. Keep a firm grip on the handles and maintain a balanced stance.

- Complete the cut: Continue the forward motion until you reach the end of the cut. Release the trigger switch to stop the blade rotation, and allow the blade to come to a complete stop before lifting the saw from the workpiece.

- Inspect the cut: Examine the cut to ensure it is clean and accurate. If necessary, use sandpaper or a file to smooth any rough edges or imperfections.

Remember to always prioritize safety while making straight cuts. Use appropriate safety gear, such as safety glasses and ear protection, and follow safety precautions outlined in the manufacturer’s guidelines.

With practice, you will improve your skills in making straight cuts with a circular saw. Take your time, stay focused, and pay attention to the alignment to achieve precise and professional-looking results.

When using a circular saw, always wear safety goggles to protect your eyes from flying debris. This is essential for preventing potential injuries.

Making Angled Cuts

Angled cuts add versatility and intricacy to your woodworking projects. With a circular saw, you can easily make bevel cuts at various angles. Follow these steps to create precise and accurate angled cuts:

- Measure and mark: Determine the desired angle for your cut and measure and mark the appropriate location on your workpiece. Use a protractor or angle gauge to ensure accuracy.

- Adjust the bevel angle: Locate the bevel adjustment mechanism on your circular saw, typically a lever or knob near the base plate. Loosen the mechanism to allow for adjustment of the base plate angle.

- Set the desired angle: Tilt the base plate to the desired bevel angle. Ensure that the angle scale or indicator on the saw matches your desired angle. Tighten the bevel adjustment mechanism to secure the base plate in place.

- Align the saw: Position the circular saw so that the blade aligns with the cutting line you marked on the workpiece. Take care to align the blade precisely with the correct angle.

- Prepare for the cut: Adjust the depth of the blade to the appropriate setting, ensuring that it extends slightly below the bottom surface of the workpiece.

- Start the cut: Hold the saw firmly with both hands, one on the handle and the other on the auxiliary handle if available. Position the base plate firmly on the workpiece, making sure it remains stable. Activate the saw and let the blade reach its full speed.

- Guide the cut: Slowly push the saw forward along the cutting line, maintaining a steady pace. Use both hands to guide the saw smoothly and follow the line accurately as you make the angled cut.

- Maintain control: Apply even pressure on the saw throughout the cut, keeping it stable and preventing it from veering off the line. Keep a firm grip on the handles and maintain a balanced stance.

- Complete the cut: Continue the forward motion until you reach the end of the cut. Release the trigger switch to stop the blade rotation, and allow the blade to come to a complete stop before lifting the saw from the workpiece.

- Inspect the cut: Examine the cut to ensure it is clean and accurate. If necessary, use sandpaper or a file to smooth any rough edges or imperfections.

Always prioritize safety when making angled cuts. Follow all safety precautions outlined in the manufacturer’s guidelines, wear appropriate safety gear, and use caution to prevent accidents.

With practice and attention to the angles and alignment, you will become proficient in making precise and professional angled cuts with your circular saw.

Rip Cutting with a Circular Saw

Rip cutting is the process of making a straight cut along the length of a material with the grain. It is a common technique used in woodworking projects. While a table saw is often the preferred tool for rip cutting, you can also accomplish this task with a circular saw. Follow these steps to rip cut with a circular saw:

- Measure and mark: Measure and mark the desired width of the rip cut on your workpiece. Use a measuring tape and a straightedge to ensure accuracy.

- Prepare the saw and workpiece: Ensure that your circular saw is properly set up, including adjusting the blade depth and making sure the workpiece is secured to prevent movement during the cut.

- Position the guide: Place a straight guide, such as a straight board or a commercial guide rail, along the marked cutting line. The guide ensures a straight and consistent cut.

- Align the saw: Position the circular saw with the side of the base plate snug against the guide. The saw’s blade should be on the side of the cutting line away from you.

- Start the cut: Hold the saw firmly with both hands, one on the handle and the other on the auxiliary handle if available. Activate the saw and let the blade reach its full speed.

- Guide the cut: Begin pushing the saw forward along the guide, maintaining a steady pace. Use both hands to guide the saw smoothly and ensure it stays flush against the guide throughout the cut.

- Maintain control: Apply even pressure on the saw and keep it stable as you continue to push it forward along the guide. Keep a firm grip on the handles and maintain a balanced stance.

- Complete the cut: Continue the forward motion until you reach the end of the material. Release the trigger switch to stop the blade rotation, and allow the blade to come to a complete stop before lifting the saw from the workpiece.

- Inspect the cut: Examine the cut to ensure it is clean and straight. If needed, use sandpaper or a file to smooth any rough edges.

As always, prioritize safety while rip cutting with a circular saw. Follow all safety precautions, wear appropriate safety gear, and exercise caution to prevent accidents.

With practice and careful attention to the guide, you can achieve precise and professional rip cuts using a circular saw.

Crosscutting with a Circular Saw

Crosscutting involves making cuts across the width of a material, usually perpendicular to the grain. While a miter saw or a table saw is commonly used for crosscutting, you can also achieve accurate and clean crosscuts with a circular saw. Follow these steps to crosscut with a circular saw:

- Measure and mark: Measure and mark the desired length of the crosscut on your workpiece. Use a measuring tape and a square to ensure accurate markings.

- Prepare the saw and workpiece: Set up your circular saw, including adjusting the blade depth and ensuring the workpiece is secure and stable.

- Position a guide: Place a straight guide, such as a straight board or a commercial guide rail, along the marked cutting line. The guide helps to ensure a straight and precise crosscut.

- Align the saw: Position the circular saw with the side of the base plate snug against the guide. The saw’s blade should be on the side of the cutting line away from you.

- Start the cut: Hold the saw firmly with both hands, one on the handle and the other on the auxiliary handle if available. Activate the saw and let the blade reach its full speed.

- Guide the cut: Begin pushing the saw forward along the guide, making sure the blade stays aligned with the cutting line. Use both hands to guide the saw smoothly and keep it flush against the guide throughout the cut.

- Maintain control: Apply even pressure on the saw and keep it stable as you continue to push it forward along the guide. Ensure a firm grip on the handles and maintain a balanced stance.

- Complete the cut: Continue the forward motion until you reach the end of the material. Release the trigger switch to stop the blade rotation, and allow the blade to come to a complete stop before lifting the saw from the workpiece.

- Inspect the cut: Examine the cut to ensure it is clean and square. If needed, use sandpaper or a file to smooth any rough edges.

Always prioritize safety while crosscutting with a circular saw. Follow all safety precautions, wear appropriate safety gear, and exercise caution to prevent accidents.

With practice and attention to the guide, you can achieve precise and professional crosscuts using a circular saw.

Read more: 15 Amazing Cordless Circular Saws

Advanced Techniques and Tips

Once you have mastered the basic skills of using a circular saw, you can explore advanced techniques to enhance your woodworking projects. Here are some tips and techniques to take your circular saw skills to the next level:

- Using a Guide Rail: A guide rail, also known as a track, can help you achieve straight and precise cuts over longer distances. Secure the guide rail in position and follow it with the saw to ensure accurate and repeatable cuts.

- Creating Dado Cuts: With the use of a dado blade or multiple passes, you can create dado cuts, which are grooves or channels in a material. This technique is commonly used for joinery or inserting shelves into furniture.

- Making Rabbet Joints: A rabbet joint involves creating a groove or notch along the edge of a material to fit another piece. You can use a circular saw and chisel to make precise rabbet joints for cabinet backs, drawer bottoms, and more.

- Bevel Ripping: By adjusting the blade angle, you can make bevel rip cuts, which add an angled edge to your workpieces. This technique is useful for creating decorative edges or beveled joints.

- Using a Speed Square: A speed square can help you make accurate angled cuts. Simply place the square against the workpiece and align the saw’s base plate to the appropriate angle indicated on the square.

- Miter Cutting: To make miter cuts for angled joints, use a miter gauge or a protractor to measure and mark the desired angle. Set the circular saw’s bevel angle and guide it along the marked line for precise miter cuts.

- Cutting Curves: While a circular saw is primarily designed for straight cuts, you can also cut gentle curves by making small, controlled movements along the desired curve. This technique works best with thin materials and requires practice for accuracy.

- Using a Zero-Clearance Insert: For clean cuts with minimal tear-out, consider using a zero-clearance insert. This insert supports the material right up to the blade, minimizing chip-out and ensuring a clean finish.

- Keeping the Blade Sharp: Regularly check and sharpen the blade to maintain optimal cutting performance. A dull blade can cause splintering and require more effort to make cuts.

- Investing in Advanced Accessories: Consider investing in advanced accessories such as laser guides, LED lights, or dust extraction systems to improve accuracy, visibility, and overall efficiency.

Remember to always prioritize safety and practice on scrap materials before attempting advanced techniques. With time and experience, you’ll develop the skills and confidence to incorporate these techniques into your woodworking projects.

Maintenance and Care for Your Circular Saw

Proper maintenance and care are essential to keep your circular saw in optimal condition and ensure safe and reliable operation. Follow these guidelines to maintain the longevity and performance of your saw:

- Regular Cleaning: After each use, clean the saw to remove dust, debris, and sawdust buildup. Use a brush or compressed air to clean the blade, motor housing, base plate, and other parts of the saw. Pay attention to the ventilation vents to prevent clogging.

- Blade Inspection: Regularly inspect the blade for any signs of damage, such as dullness, chips, or missing teeth. Replace the blade if necessary or sharpen it using the appropriate tools or seek professional assistance for blade sharpening.

- Lubrication: Apply lubricating oil to the moving parts of the saw, such as the blade arbor, depth adjustment mechanism, and bevel adjustment mechanism. Follow the manufacturer’s recommendations for the appropriate lubricant and frequency of application.

- Check, Tighten, and Replace: Routinely check all the screws, bolts, and fasteners on the saw to ensure they are tight and secure. Replace any worn or damaged parts, such as handles, cords, or safety mechanisms, as needed.

- Storage: When not in use, store your circular saw in a dry and clean location. Use a case or a dust-free storage container to protect it from dust, moisture, and potential damage. Avoid storing it in extreme temperatures or exposed to direct sunlight.

- Battery Maintenance: If your circular saw is cordless, follow the manufacturer’s instructions for proper care and maintenance of the battery. Ensure that the battery is fully charged before storage and avoid deep discharging or overcharging.

- Professional Servicing: Periodically, consider taking your circular saw to a professional for service and inspection. They can conduct a thorough check, perform necessary adjustments, and address any potential issues to keep your saw running smoothly.

- Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s instruction manual for specific maintenance instructions and safety guidelines. Stay updated on any product recalls or safety notices issued by the manufacturer.

Proper maintenance and care not only extend the lifespan of your circular saw but also maximize its safety and performance. By investing time and effort in maintaining your saw, you can enjoy precise cuts and a reliable tool for your woodworking projects.

Conclusion

The circular saw is a powerful and versatile tool that opens up a world of possibilities for DIY enthusiasts and professional carpenters alike. By understanding how to use a circular saw safely and effectively, you can confidently tackle a wide range of woodworking projects with precision and efficiency.

In this comprehensive guide, we covered the essential aspects of using a circular saw, from selecting the right saw for your needs to adjusting the blade depth and bevel angle. We explored techniques for making straight cuts, angled cuts, rip cuts, and crosscuts, providing step-by-step instructions on how to execute each one successfully.

We also delved into advanced techniques and tips that can take your circular saw skills to the next level. Whether it’s creating dado cuts, making rabbet joints, or using a guide rail for more precise cuts, these techniques offer added versatility to your woodworking endeavors.

Finally, we emphasized the importance of maintenance and care for your circular saw. By properly cleaning, inspecting, and lubricating your saw, you can ensure its longevity and optimum performance. Regular maintenance also promotes safety by identifying and addressing any potential issues before they become more significant problems.

Remember, safety should always be a priority when working with a circular saw. Always follow the manufacturer’s guidelines, wear appropriate safety gear, and practice caution to prevent accidents and injuries. Take the time to familiarize yourself with the specific features and functions of your saw before using it.

Now that you have the knowledge and skills to effectively utilize a circular saw, you can embark on your woodworking projects with confidence. Happy cutting!

Frequently Asked Questions about How To Use A Circular Saw

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use A Circular Saw”