Home>Home Maintenance>How To Install A Ventilation System To Comply With The Indiana Energy Code

Home Maintenance

How To Install A Ventilation System To Comply With The Indiana Energy Code

Modified: March 6, 2024

Learn how to install a ventilation system that meets the Indiana Energy Code requirements for your home with our expert home maintenance tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to this comprehensive guide on how to install a ventilation system that complies with the Indiana Energy Code. Proper ventilation is essential in any building to maintain a healthy and comfortable living or working environment. In Indiana, the Energy Code sets specific requirements for ventilation systems to ensure efficient energy usage and occupant safety.

Whether you are a homeowner, property manager, or contractor, understanding and meeting these regulations is crucial. By following this step-by-step guide, you will learn how to assess your ventilation needs, select the appropriate system, gather the necessary materials and tools, install the ductwork and vents, connect the system to power, test and balance the ventilation, and ultimately obtain compliance certification.

Improperly installed ventilation systems can result in poor indoor air quality, energy waste, and potential health hazards. Therefore, it is essential to follow the Indiana Energy Code guidelines to ensure proper installation and compliance. So, let’s dive into the details and get your ventilation system installed correctly!

Key Takeaways:

- Proper ventilation is crucial for a healthy indoor environment. By following Indiana Energy Code guidelines, you can install a compliant system that ensures energy efficiency and occupant comfort.

- Assessing ventilation needs, selecting the right system, and obtaining compliance certification are key steps in the installation process. Attention to detail and professional assistance contribute to a successful outcome.

Read more: How To Install Broan Range Hood

Understanding the Indiana Energy Code

The Indiana Energy Code is a set of regulations established by the state to promote energy efficiency and sustainability in buildings. It applies to both residential and commercial construction projects and covers various aspects, including insulation, HVAC systems, lighting, and ventilation.

When it comes to ventilation, the code specifies minimum requirements to ensure proper airflow, fresh air intake, and air quality within a building. These requirements vary depending on the type of space, such as residential, commercial, or industrial, as well as the occupancy and size of the building.

One of the key principles of the Indiana Energy Code is the promotion of energy conservation while maintaining indoor air quality. The code emphasizes the use of ventilation systems that can efficiently exchange stale air for fresh air while minimizing energy loss.

Here are some important aspects to consider when understanding the Indiana Energy Code regarding ventilation:

- Air Change Rate: The code defines the minimum number of air changes per hour (ACH) required for different spaces. This ensures a sufficient flow of fresh air, which is crucial for the health and comfort of occupants.

- Ventilation Rates: The code specifies the minimum ventilation rates, measured in cubic feet per minute (CFM), based on the occupancy and square footage of the space. These rates determine the airflow needed to maintain a healthy and comfortable environment.

- Exhaust Ventilation: Certain areas, such as kitchens and bathrooms, require exhaust ventilation to remove moisture, odors, and pollutants. The code provides guidelines on the type and capacity of exhaust systems to be installed.

- Ventilation Controls: The code outlines the requirements for ventilation control mechanisms, such as timers, sensors, and manual switches. These controls help optimize energy usage by adjusting the ventilation system based on occupancy and activity levels.

Complying with the Indiana Energy Code ensures that your ventilation system meets the minimum standards for energy efficiency and indoor air quality. It not only benefits the occupants of the building but also contributes to a greener and more sustainable future.

Assessing Ventilation Needs in Your Building

Before you can begin installing a ventilation system that complies with the Indiana Energy Code, it’s crucial to assess the specific ventilation needs of your building. This assessment will help determine the appropriate ventilation rates, air change rates, and exhaust requirements, ensuring that the system is adequately designed for optimal performance.

Here are some steps to follow when assessing the ventilation needs in your building:

- Evaluate the Space: Start by evaluating the different areas within your building that require ventilation. Consider the occupancy, function, and size of each space, as well as any specific requirements stipulated by the Indiana Energy Code. Spaces such as kitchens, bathrooms, and laundry rooms may have higher ventilation needs compared to bedrooms or living areas.

- Determine Air Change Rates: The Indiana Energy Code specifies the minimum air change rates required for different spaces. Calculate the required air changes per hour (ACH) based on the square footage and occupancy of each area. This will give you a baseline for the volume of air that needs to be exchanged within the space.

- Consider Occupant Health and Comfort: While meeting the minimum requirements of the Indiana Energy Code is essential, it’s also important to consider the health and comfort of the occupants. Factors such as temperature, humidity, indoor air quality, and noise levels should be taken into account when determining the ventilation needs. This may involve additional measures, such as providing enhanced filtration or incorporating sound-dampening materials.

- Assess Local Climate and Environmental Factors: The regional climate and environmental conditions can impact the ventilation requirements. For instance, buildings located in hot and humid climates may require additional ventilation to ensure effective heat dissipation and moisture control. Consider any specific local regulations or recommendations that may influence the ventilation design.

- Consult with Professionals: If you are unsure about the ventilation needs of your building or find the assessment process challenging, it’s recommended to consult with professionals, such as mechanical engineers or HVAC contractors, who are knowledgeable about the Indiana Energy Code requirements. They can provide expert guidance and help ensure that the ventilation system is designed correctly.

By thoroughly assessing the ventilation needs in your building, you can lay a solid foundation for designing and installing a ventilation system that meets the Indiana Energy Code requirements. This will not only ensure compliance but also contribute to a healthy, comfortable, and energy-efficient indoor environment for the occupants.

Selecting the Right Ventilation System

Once you have assessed the ventilation needs of your building, the next step is to select the right ventilation system that aligns with the requirements set forth by the Indiana Energy Code. Choosing the appropriate system will ensure efficient airflow, proper ventilation rates, and compliance with the code.

Here are some factors to consider when selecting the right ventilation system:

- Ventilation Type: There are various types of ventilation systems available, each with its own benefits and suitability for different spaces. Common types include mechanical ventilation, natural ventilation, and hybrid ventilation systems. Evaluate the advantages and limitations of each type based on your building layout, occupancy, and energy efficiency goals.

- Ventilation Rate: Refer to the ventilation rates specified in the Indiana Energy Code for each space in your building. Ensure that the selected ventilation system can provide the required air changes per hour (ACH) or cubic feet per minute (CFM) to meet these rates. The system should be capable of effectively exchanging stale air with fresh outdoor air to maintain indoor air quality.

- Energy Efficiency: Energy efficiency is a key consideration when selecting a ventilation system. Look for systems that are designed to minimize energy loss while delivering efficient ventilation. Integrated energy recovery ventilation (ERV) or heat recovery ventilation (HRV) systems can help recover and reuse heat or coolness from the outgoing air, reducing energy consumption.

- Noise Considerations: Take into account the noise levels generated by different ventilation systems. Some systems, such as ducted fans or large air handling units, can produce noticeable noise. Ensure that the selected system operates at an acceptable noise level, especially in areas where noise sensitivity is a concern, such as bedrooms or offices.

- Air Filtration: Consider the air filtration capabilities of the ventilation system, particularly if you have specific indoor air quality concerns. Look for systems with filters that can effectively capture pollutants, allergens, and particulate matter, ensuring that the indoor air remains clean and healthy.

- Maintenance and Lifecycle Costs: Evaluate the maintenance requirements and lifecycle costs associated with different ventilation systems. Consider factors such as filter replacements, regular servicing, and potential repairs. Opt for systems that are reliable, have accessible components for maintenance, and come with reasonable warranty provisions.

It is crucial to keep in mind the specific guidelines outlined in the Indiana Energy Code when selecting your ventilation system. Additionally, consult with professionals, such as HVAC contractors or mechanical engineers, who can offer expert advice and ensure that the chosen system fulfills the code requirements while addressing the unique needs of your building.

By carefully selecting the right ventilation system, you can not only meet the Indiana Energy Code specifications but also ensure optimal indoor air quality, energy efficiency, and occupant comfort in your building.

Gathering Materials and Tools

Once you have assessed your ventilation needs and selected the right ventilation system for your building, it’s time to gather the necessary materials and tools for the installation. Having the right supplies on hand will ensure a smooth and efficient installation process while adhering to the requirements of the Indiana Energy Code.

Here is a list of materials and tools you may need:

- Ventilation System Components: Depending on the type of ventilation system chosen, you may require components such as fans, ductwork, vents, grilles, dampers, filters, and air handling units. Ensure that the components are compatible with each other and meet the specifications outlined in the Indiana Energy Code.

- Ductwork Materials: Ductwork is an essential part of most ventilation systems. Determine the size and length of ducts required for your building and gather appropriate materials such as galvanized steel ducts, flexible ducts, connectors, and sealing tape. It’s important to use duct materials that are approved for HVAC applications and comply with the code and local building regulations.

- Fasteners and Support Materials: You may need screws, nuts, bolts, clamps, and hangers to secure and support the ventilation system components and ductwork. Choose fasteners that are suitable for the materials used, provide adequate strength, and comply with any applicable fire safety regulations.

- Electrical Wiring Supplies: If your ventilation system requires electrical connections, gather wiring supplies such as electrical cables, junction boxes, connectors, wire nuts, and electrical tape. It’s important to follow proper electrical wiring practices and consult with a qualified electrician for any electrical work involved.

- Insulation Materials: Depending on the location and requirements, you may need insulation materials such as fiberglass or foam board insulation to insulate the ductwork and prevent heat loss or condensation. Ensure that the insulation materials meet the required thermal insulation values and fire rating standards.

- Hand Tools: Gather a range of hand tools such as screwdrivers, wrenches, pliers, tape measure, utility knife, hammer, level, and duct cutters. These tools will be essential for cutting, attaching, and securing ventilation system components and ductwork.

- Protective Gear: Don’t forget to prioritize safety by wearing appropriate protective gear, including gloves, safety glasses, ear protection, and a dust mask. Ventilation installation may involve working with sharp objects, electrical connections, and insulation materials, so it’s important to protect yourself from potential hazards.

Remember to review the Indiana Energy Code and any additional local building requirements to ensure that the materials and tools you gather comply with the regulations.

By gathering the necessary materials and tools ahead of time, you can streamline the installation process, minimize delays, and ensure that you have everything you need to complete the ventilation system installation in compliance with the Indiana Energy Code.

Read more: How To Install A Vissani Range Hood

Preparing the Installation Area

Before you begin installing the ventilation system, it’s important to properly prepare the installation area. This step will ensure a safe and efficient installation process while adhering to the guidelines of the Indiana Energy Code. Preparing the area involves clearing the space, making necessary adjustments, and ensuring proper access for the installation of the ventilation components.

Here are some steps to follow when preparing the installation area for your ventilation system:

- Clear the Space: Remove any obstructions, furniture, or equipment from the area where the ventilation system will be installed. This will provide you with a clear and open workspace, making it easier to maneuver and install the components.

- Ensure Proper Access: Make sure there is sufficient access to the area where the ventilation system will be installed. This includes ensuring that doors, windows, and other openings are wide enough to accommodate the ventilation components and any required equipment for installation.

- Check for Structural Integrity: Assess the integrity of the structure where the ventilation system will be installed. This includes examining the walls, ceilings, and floors to ensure they are sturdy and capable of supporting the weight of the ventilation components. Seek professional advice if any structural concerns arise.

- Seal Air Leaks: Inspect the installation area for any air leaks. Seal any gaps, cracks, or openings in the walls, ceilings, and floors using appropriate sealants or caulking materials. This helps prevent air leakage, ensuring that the ventilation system functions efficiently.

- Plan Ductwork Routes: Determine the routes for the ductwork, taking into consideration the most direct and efficient paths while avoiding any obstacles or obstructions. Plan the placement of vents and grilles in each space to ensure proper air distribution and circulation throughout the building.

- Consider Fire Safety: Ensure that the installation area and surrounding areas comply with fire safety requirements. Pay attention to clearances from combustible materials, such as insulation or nearby electrical wiring. Follow the Indiana Energy Code guidelines and consult local building regulations to ensure compliance.

- Secure Necessary Permits: Check if the installation of the ventilation system requires any permits or approvals. Obtain the necessary permits from the relevant authorities before proceeding with the installation. Failure to obtain permits may result in penalties or the need to redo the installation.

By adequately preparing the installation area, you create a suitable environment for the installation of your ventilation system. This ensures not only compliance with the Indiana Energy Code but also a seamless and efficient installation process.

When installing a ventilation system to comply with the Indiana Energy Code, make sure to properly size the system according to the square footage of the space and follow the manufacturer’s guidelines for installation.

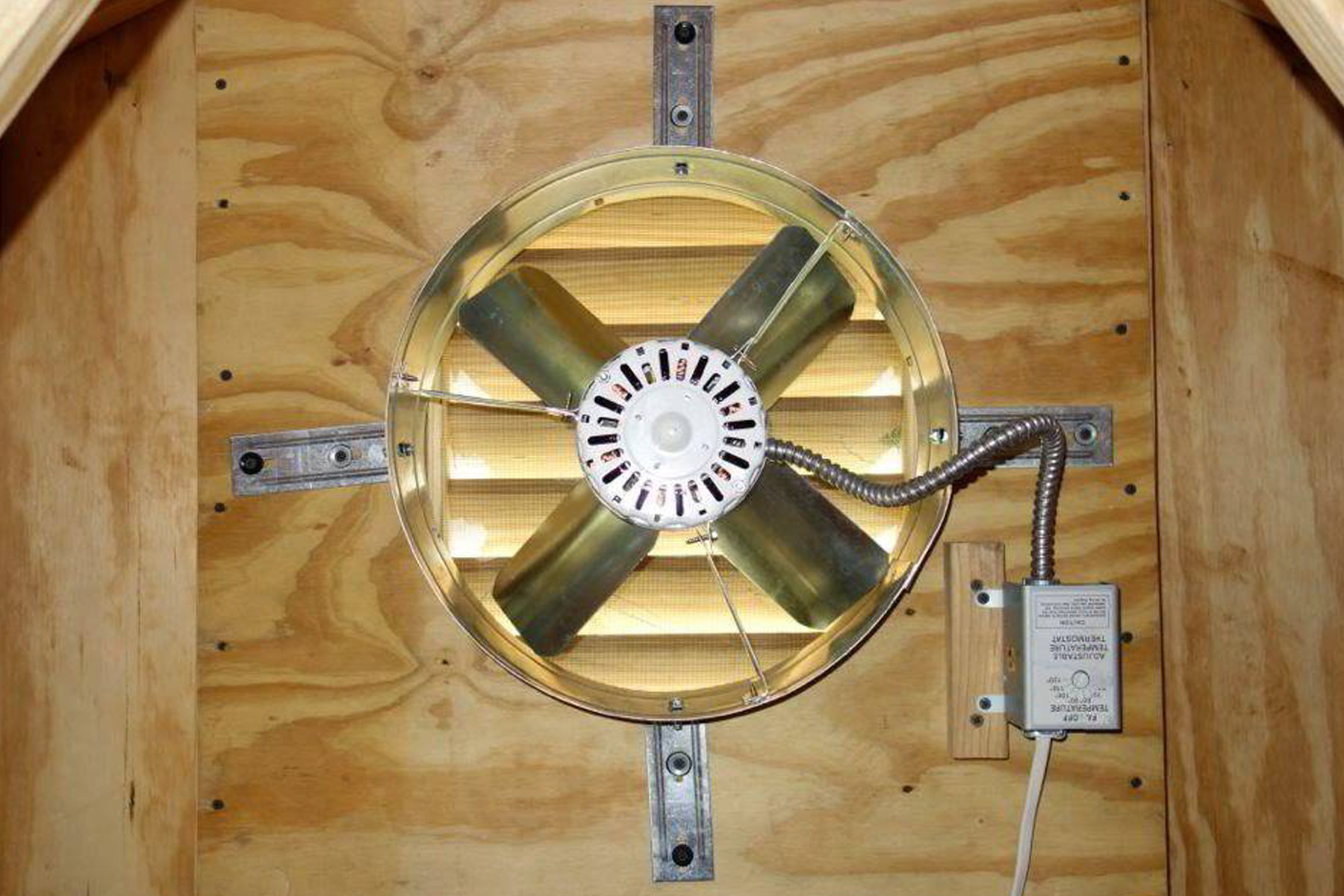

Installing Ductwork and Vents

Once you have prepared the installation area, it’s time to start installing the ductwork and vents for your ventilation system. This step is crucial as it determines how effectively air will be distributed throughout the building, ensuring compliance with the Indiana Energy Code. Proper installation of ductwork and vents requires attention to detail and adherence to specific guidelines.

Here are the steps to follow when installing ductwork and vents:

- Measure and Cut the Ductwork: Begin by measuring the required lengths of ductwork based on your planned route. Use a tape measure and mark the ductwork accordingly. Next, use appropriate tools such as duct cutters or aviation snips to make clean and precise cuts in the ductwork.

- Connect the Ductwork Sections: Connect the ductwork sections using the appropriate connectors or couplings. Ensure the connections are secure and airtight to prevent air leaks. Depending on the type of ductwork material, you may need to use screws, clamps, or foil tape to secure the connections.

- Position and Secure Ductwork: Position the ductwork along the planned route, ensuring proper clearances as per the Indiana Energy Code and any applicable building regulations. Use hangers or straps to secure the ductwork to the ceiling or walls, ensuring stability and preventing sagging or excessive movement.

- Install Vents and Grilles: Install vents and grilles at appropriate locations to allow air to enter or exit the ductwork. Cut openings in the walls, ceilings, or floors as necessary to accommodate the vents. Use appropriate screws or fasteners to secure the vents in place, ensuring a tight fit against the surface.

- Seal Ductwork Joints: Inspect all ductwork joints and connections for any gaps or air leaks. Seal any gaps with approved duct sealant or aluminum foil tape to ensure airtight connections. Properly sealed ductwork helps maintain efficient airflow and prevents energy loss.

- Connect Ductwork to Equipment: Connect the ductwork to the ventilation system equipment, such as fans or air handling units, following the manufacturer’s instructions. Ensure that the connections are secure and properly aligned, allowing for the efficient transfer of air.

- Inspect and Test: Once the ductwork and vents are installed, thoroughly inspect the entire system to ensure proper alignment, sealant integrity, and secure connections. Conduct a airflow test to ensure that air is flowing as intended and that there are no significant obstructions or leaks within the system.

It’s important to note that the installation of ductwork and vents may require specific knowledge and tools. If you’re unsure about any step or encounter difficulties during the process, it’s best to seek assistance from HVAC professionals who have experience in ventilation system installations.

By properly installing the ductwork and vents, you are laying the foundation for an efficient and compliant ventilation system. This step plays a crucial role in maintaining indoor air quality, promoting energy efficiency, and ensuring occupant comfort within the building.

Connecting the Ventilation System to Power

After successfully installing the ductwork and vents for your ventilation system, the next step is to connect the system to a power source. This step is essential to ensure the proper functioning of the ventilation system, as it relies on electrical power to operate fans, motors, and control mechanisms. Connecting the ventilation system to power should be done with caution, following electrical safety guidelines and the requirements of the Indiana Energy Code.

Here are the steps to follow when connecting the ventilation system to power:

- Locate the Power Source: Identify the nearest electrical power source or circuit that will supply power to the ventilation system. This may be an existing electrical outlet or junction box, or a dedicated circuit specifically designed for the ventilation system. Ensure that the power source meets the electrical requirements specified by the manufacturer and complies with the local electrical codes.

- Turn off the Power: Prior to making any electrical connections, ensure that the power to the designated circuit is turned off at the main electrical panel. This step is critical to prevent any potential electrical hazards, such as electric shock or short circuits.

- Wiring Connections: Follow the manufacturer’s instructions for the specific ventilation system and make the necessary electrical connections. This typically involves connecting the power supply wires to the designated terminals or wiring points on the ventilation system equipment. Use appropriate electrical connectors, such as wire nuts or terminal blocks, and ensure that the connections are secure and properly insulated.

- Grounding: Proper grounding is crucial for electrical safety. Ensure that the ventilation system is properly grounded as per the manufacturer’s instructions and the requirements of the local electrical codes. This helps protect against electrical shocks and ensures safe operation of the system.

- Verify Voltage Compatibility: Double-check the voltage requirements of the ventilation system equipment and compare them to the voltage supplied by the electrical circuit. Ensure that they are compatible. If necessary, use a multimeter to verify the voltage before connecting the ventilation system to power.

- Double-Check Connections: Before restoring power, carefully inspect all electrical connections to ensure that they are properly tightened, adequately insulated, and free from any damage or loose wires. This step is crucial for electrical safety and to prevent potential issues, such as overheating or electrical fires.

- Restore Power and Test: Once you are confident that all electrical connections are secure and in compliance with the manufacturer’s instructions, you can restore power to the designated circuit. Test the ventilation system to ensure that it functions as intended, including activating fans, motors, and any control mechanisms. Pay attention to any abnormal noises, vibrations, or malfunctions and resolve them promptly.

It’s worth mentioning that electrical work should ideally be conducted by a licensed electrician to ensure compliance with electrical codes and safety standards. If you’re not comfortable or experienced in dealing with electrical connections, it is highly recommended to seek professional assistance.

By connecting the ventilation system to power correctly, you will enable the system to function efficiently and ensure a well-operating ventilation system that complies with both the Indiana Energy Code and electrical safety guidelines.

Testing and Balancing the Ventilation System

After completing the installation and connecting the ventilation system to power, the next crucial step is to test and balance the system. Testing and balancing ensure that the ventilation system operates at optimal performance, providing adequate airflow, and meeting the requirements of the Indiana Energy Code. This step also helps identify any issues or adjustments needed to achieve proper air distribution and ensure occupant comfort.

Here are the steps to follow when testing and balancing the ventilation system:

- Inspect the System: Conduct a visual inspection of the entire ventilation system, including the ductwork, vents, fans, and controls. Check for any signs of damage, loose connections, or obstructions. Ensure that all components are properly installed and aligned according to the manufacturer’s instructions and the Indiana Energy Code.

- Airflow Measurement: Use an airflow measurement device, such as an anemometer or flow hood, to measure the actual airflow at various vents and ducts. This step helps determine if the airflow matches the design specifications and identifies any variations or imbalances.

- Adjust Dampers and Registers: If there are significant variations in airflow or imbalances, adjust the dampers or registers to achieve a more consistent flow. This may involve partially closing or opening dampers or adjusting the position of supply registers or grilles to redirect the airflow as needed.

- Check Fan Performance: Test the performance of the ventilation system’s fan(s) to ensure they are operating at the specified speed and meeting the manufacturer’s recommendations. Verify that the fan(s) are adequately extracting stale air or supplying fresh air, in accordance with the Indiana Energy Code.

- Measure Noise Levels: Use a sound level meter to measure the noise levels generated by the ventilation system. Check if the noise levels are within acceptable limits, especially in areas where low noise levels are desired, such as bedrooms or office spaces. Adjustments may be necessary to minimize noise, such as adding sound attenuators or modifying the ductwork layout.

- Air Quality Evaluation: Assess the indoor air quality in various areas throughout the building. Measure and monitor parameters such as temperature, humidity, and carbon dioxide levels to ensure they are within acceptable ranges. If any areas have poor air quality, consider adjustments to the ventilation system or additional measures such as air purifiers or improved filtration.

- Record Keeping and Documentation: Maintain detailed records of the test results, adjustments made, and any issues or observations encountered during the testing and balancing process. This documentation will be valuable for future reference, maintenance, and compliance purposes.

It’s recommended to consult with HVAC professionals or qualified technicians who have experience with ventilation system testing and balancing. They will have the necessary expertise and equipment to ensure accurate measurements and proper adjustment of the system.

By thoroughly testing and balancing the ventilation system, you can optimize airflow, enhance indoor air quality, and ensure compliance with the Indiana Energy Code. A well-balanced ventilation system will contribute to a comfortable and healthy environment for occupants while maximizing energy efficiency.

Read more: How To Install ZLINE Range Hood

Inspecting and Obtaining Compliance Certification

After installing and testing your ventilation system to ensure it meets the requirements of the Indiana Energy Code, the final step is to inspect the system and obtain compliance certification. This certification confirms that your ventilation system is in alignment with the regulations set forth by the code and meets all the necessary standards for energy efficiency and safety.

Here are the steps to follow when inspecting and obtaining compliance certification:

- Hire a qualified inspector: Contact a qualified inspector who specializes in ventilation system inspections. Ensure that the inspector is knowledgeable about the Indiana Energy Code requirements and has experience in assessing ventilation systems.

- Schedule the inspection: Coordinate with the inspector to schedule a convenient time for the inspection. Ensure that the ventilation system is fully accessible and operational during the inspection.

- Prepare necessary documentation: Gather all the relevant documentation related to your ventilation system, including installation plans, equipment specifications, testing results, and any permits that were obtained during the installation process.

- Conduct the inspection: During the inspection, the qualified inspector will assess various aspects of your ventilation system, such as the integrity of the ductwork, proper installation of components, compliance with the airflow and ventilation rate requirements, electrical connections, and overall functionality.

- Address any concerns or recommendations: If the inspector identifies any issues or areas that require attention, take note of their recommendations. Address these concerns in a timely manner to ensure that the ventilation system meets all the necessary requirements.

- Obtain compliance certification: Once the inspection is successfully completed and any necessary adjustments have been made, the qualified inspector will issue a compliance certification. This certification affirms that your ventilation system is compliant with the Indiana Energy Code and meets all applicable standards.

- Keep records: It’s important to keep a copy of the compliance certification, along with all other relevant documentation, for future reference and potential future inspections. These records will serve as proof of compliance and can be beneficial if you decide to sell or lease the property in the future.

Obtaining compliance certification ensures that your ventilation system is operating within the guidelines of the Indiana Energy Code. It provides assurance that your building is equipped with a properly functioning and compliant ventilation system that promotes energy efficiency and maintains a healthy indoor environment.

Remember to consult local regulatory authorities for specific requirements and guidelines relating to compliance certification. They can provide further guidance and assist you in navigating the certification process.

Conclusion

Installing a ventilation system that complies with the Indiana Energy Code is essential for maintaining a healthy, comfortable, and energy-efficient environment in your building. By following the steps outlined in this comprehensive guide, you can ensure that your ventilation system meets the necessary requirements and operates at optimal performance.

From understanding the Indiana Energy Code and assessing your ventilation needs to selecting the right system, gathering materials and tools, preparing the installation area, and connecting the system to power, each step in the process plays a crucial role in a successful installation. Testing, balancing, inspecting, and obtaining compliance certification are the final steps that ensure the system meets the required standards and regulations.

Throughout the installation process, it’s important to pay attention to detail, prioritize safety, and seek professional assistance when needed. Compliance with the Indiana Energy Code not only ensures that your ventilation system meets minimum standards but also contributes to energy conservation, improved air quality, and occupant comfort.

Remember to keep documentation and records of the installation, testing, and certification process. These records serve as valuable references for future maintenance, inspections, and potential property transactions.

By following this guide, you can achieve a properly installed and compliant ventilation system that not only meets the Indiana Energy Code requirements but also promotes a healthier and more sustainable indoor environment for the occupants of your building.

Frequently Asked Questions about How To Install A Ventilation System To Comply With The Indiana Energy Code

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Install A Ventilation System To Comply With The Indiana Energy Code”