Home>Technology>Smart Home Devices>Why Does My 3D Printer Keep Messing Up

Smart Home Devices

Why Does My 3D Printer Keep Messing Up

Modified: January 19, 2024

Discover common issues with smart home devices and learn how to troubleshoot them. Find out why your 3D printer keeps messing up and how to fix it.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Read more: Why Is My 3D Printer Clicking

Introduction

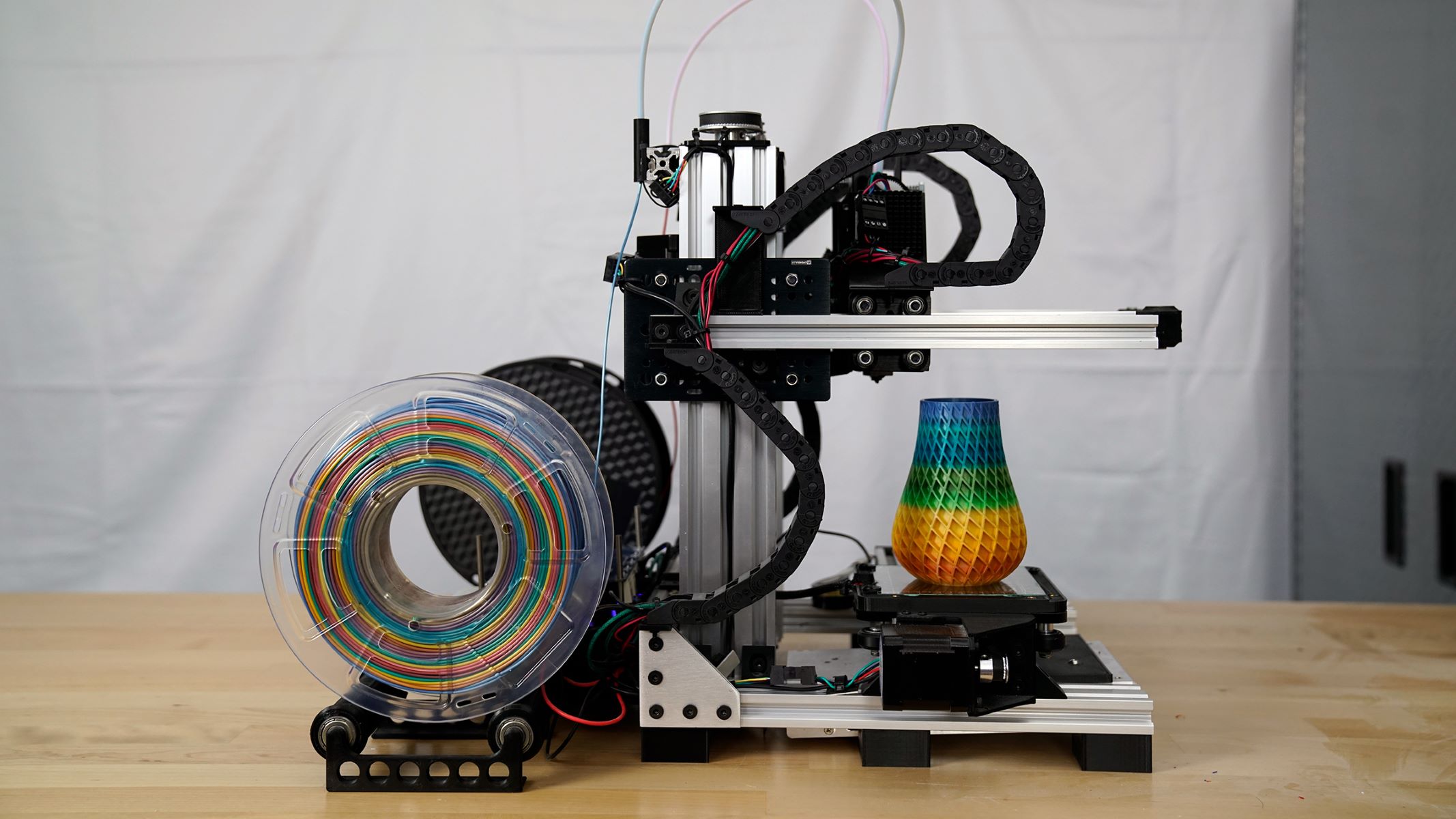

Welcome to the fascinating world of 3D printing! As a proud owner of a 3D printer, you're undoubtedly excited about the endless possibilities it offers. Whether you're a hobbyist, a DIY enthusiast, or a professional creator, 3D printing opens up a realm of creativity and innovation. However, as with any technology, 3D printing can sometimes be a bit finicky, leading to frustration and confusion. If you've found yourself asking, "Why does my 3D printer keep messing up?" you're not alone.

In this comprehensive guide, we'll delve into the common issues that can plague 3D printing, causing unexpected hiccups in your printing projects. From filament troubles to software glitches, we'll explore the potential culprits behind your 3D printing woes. By understanding these common problems and their solutions, you'll be better equipped to troubleshoot issues and achieve successful prints with confidence.

So, let's embark on this journey of unraveling the mysteries of 3D printing malfunctions. By the end of this guide, you'll have a deeper understanding of the potential pitfalls and the strategies to overcome them, empowering you to unleash the full potential of your 3D printer. Let's dive in and discover the secrets to overcoming the challenges that may be hindering your 3D printing endeavors.

Key Takeaways:

- 3D printing can be frustrating, but understanding and addressing common issues like adhesion problems, filament troubles, and nozzle clogs can help achieve successful prints with confidence.

- Proper bed leveling, filament management, and software/firmware maintenance are crucial for overcoming 3D printing challenges and unleashing the full potential of your 3D printer.

Common Issues with 3D Printing

3D printing, while a remarkable technology, is not without its share of common issues that can frustrate even the most experienced enthusiasts. Understanding these issues is crucial for achieving consistent and high-quality prints. Let’s explore some of the most prevalent challenges encountered in the realm of 3D printing.

1. Adhesion Problems: One of the most common issues is the lack of adhesion between the printed object and the print bed. This can result in warped or detached prints, leading to failed prints and wasted filament.

2. Layer Shifting: Layer shifting occurs when the layers of the print are not properly aligned, often caused by mechanical issues or overheating. This can result in misshapen and structurally compromised prints.

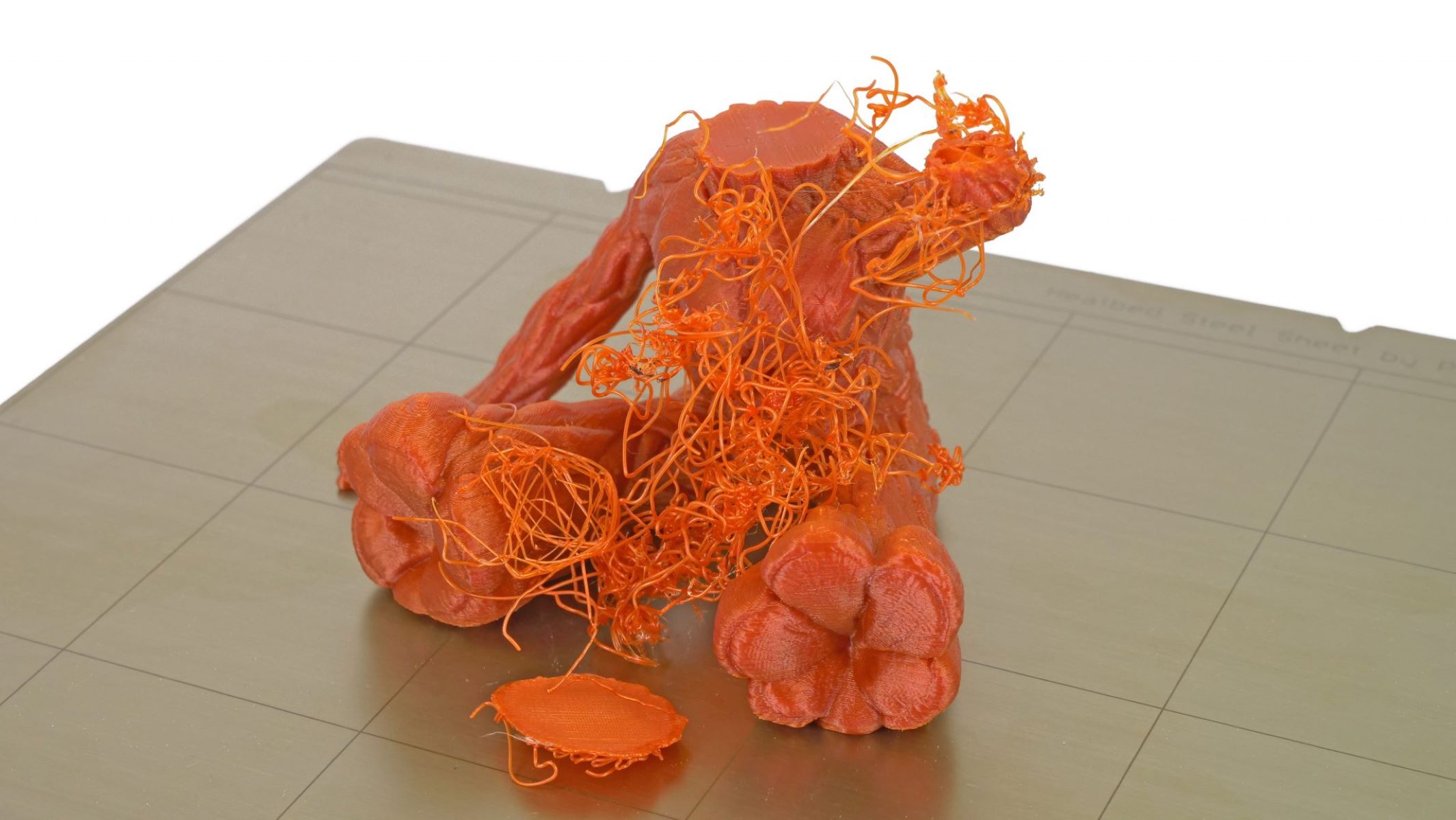

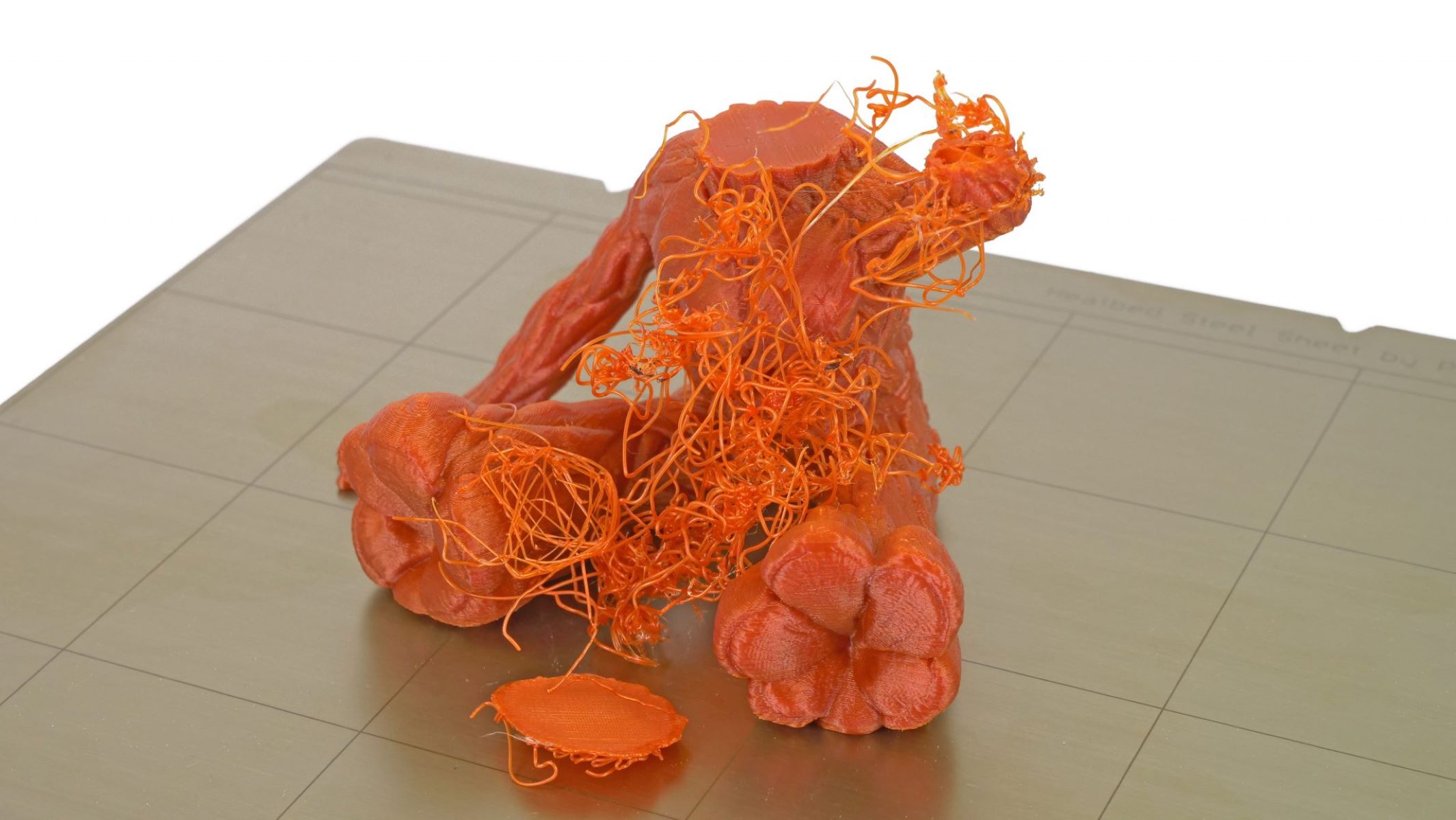

3. Stringing and Oozing: Stringing and oozing refer to the unintended extrusion of filament during travel moves, leading to unsightly string-like artifacts on the print. This can detract from the overall quality and aesthetics of the final output.

4. Warping and Cracking: Warping and cracking occur when the printed material cools unevenly, causing distortions and structural weaknesses in the final print. This is particularly common with certain materials such as ABS.

5. Inconsistent Extrusion: Inconsistent extrusion can lead to gaps and irregularities in the print, resulting in a lack of dimensional accuracy and surface finish issues.

These common issues can be frustrating, but fear not! With the right knowledge and troubleshooting techniques, these challenges can be overcome, allowing you to harness the full potential of your 3D printer. Now, let’s delve into the specific areas where these issues often originate and explore effective solutions to address them.

Filament Problems

When it comes to 3D printing, the filament is the lifeblood of the process. However, filament-related issues can often lead to frustrating print failures and subpar results. Let’s explore some common filament problems and how to address them.

1. Filament Diameter Variations: Inconsistent filament diameter can lead to extrusion issues, resulting in under-extrusion or over-extrusion. It’s crucial to ensure that your filament has a consistent diameter throughout to maintain precise extrusion.

2. Moisture Absorption: Certain filament materials, such as nylon and PVA, are prone to absorbing moisture from the environment. This can lead to popping and bubbling during extrusion, affecting print quality. Storing filament in a dry environment or using a filament dryer can help mitigate this issue.

3. Filament Tangles and Knots: Tangled or knotted filament can lead to printing interruptions and extrusion inconsistencies. Proper storage and handling of filament spools can help prevent tangles and knots, ensuring smooth and uninterrupted printing.

4. Filament Brittleness: Some filaments, particularly those with additives such as carbon fiber or metallic particles, can be prone to brittleness. This can lead to breakage during printing, causing print failures. Adjusting print settings and handling these filaments with care can help minimize brittleness-related issues.

5. Filament Quality and Contaminants: Low-quality or contaminated filament can introduce impurities into the printing process, leading to clogs and extrusion inconsistencies. Using high-quality, reputable filament brands and properly storing filament can help mitigate these issues.

By understanding and addressing these filament-related challenges, you can optimize the performance of your 3D printer and achieve consistent, high-quality prints. Now, let’s explore another critical aspect of successful 3D printing: bed leveling.

Bed Leveling Issues

Proper bed leveling is essential for ensuring optimal adhesion and print quality in 3D printing. However, bed leveling issues can often lead to frustration and failed prints. Let’s explore some common bed leveling challenges and how to address them.

1. Uneven Bed Surface: An uneven bed surface can lead to adhesion problems and inconsistent first layers. This can result in prints detaching or warping during the printing process. Regularly checking and adjusting the bed surface is crucial for maintaining proper leveling.

2. Bed Adhesion Methods: Different bed adhesion methods, such as using adhesive sprays, tapes, or specialized bed surfaces, require specific bed leveling approaches. Failing to account for the chosen adhesion method can lead to suboptimal print adhesion and quality.

3. Z-Axis Calibration: Incorrect Z-axis calibration can lead to improper nozzle-to-bed distance, impacting the first layer adhesion and print quality. Ensuring precise Z-axis calibration is essential for achieving consistent and reliable bed adhesion.

4. Bed Warping: Bed warping, particularly in heated beds, can lead to uneven printing surfaces and adhesion issues. Regularly inspecting and maintaining the bed surface, especially in heated beds, is crucial for mitigating warping-related challenges.

5. Print Bed Contamination: Contaminants on the print bed surface, such as oils, dust, or residue from previous prints, can hinder proper adhesion. Thoroughly cleaning the print bed and using appropriate cleaning methods can help maintain a pristine and conducive printing surface.

Addressing bed leveling issues is fundamental to achieving successful 3D prints. By understanding the nuances of bed leveling and implementing effective calibration and maintenance practices, you can overcome these challenges and pave the way for consistent and high-quality prints. Now, let’s explore another common culprit behind 3D printing woes: nozzle clogs.

Check the bed leveling to ensure it’s even. Clean the print nozzle regularly to prevent clogs. Use high-quality filament for better results.

Read more: Why Is My 3D Printer Filament Not Sticking

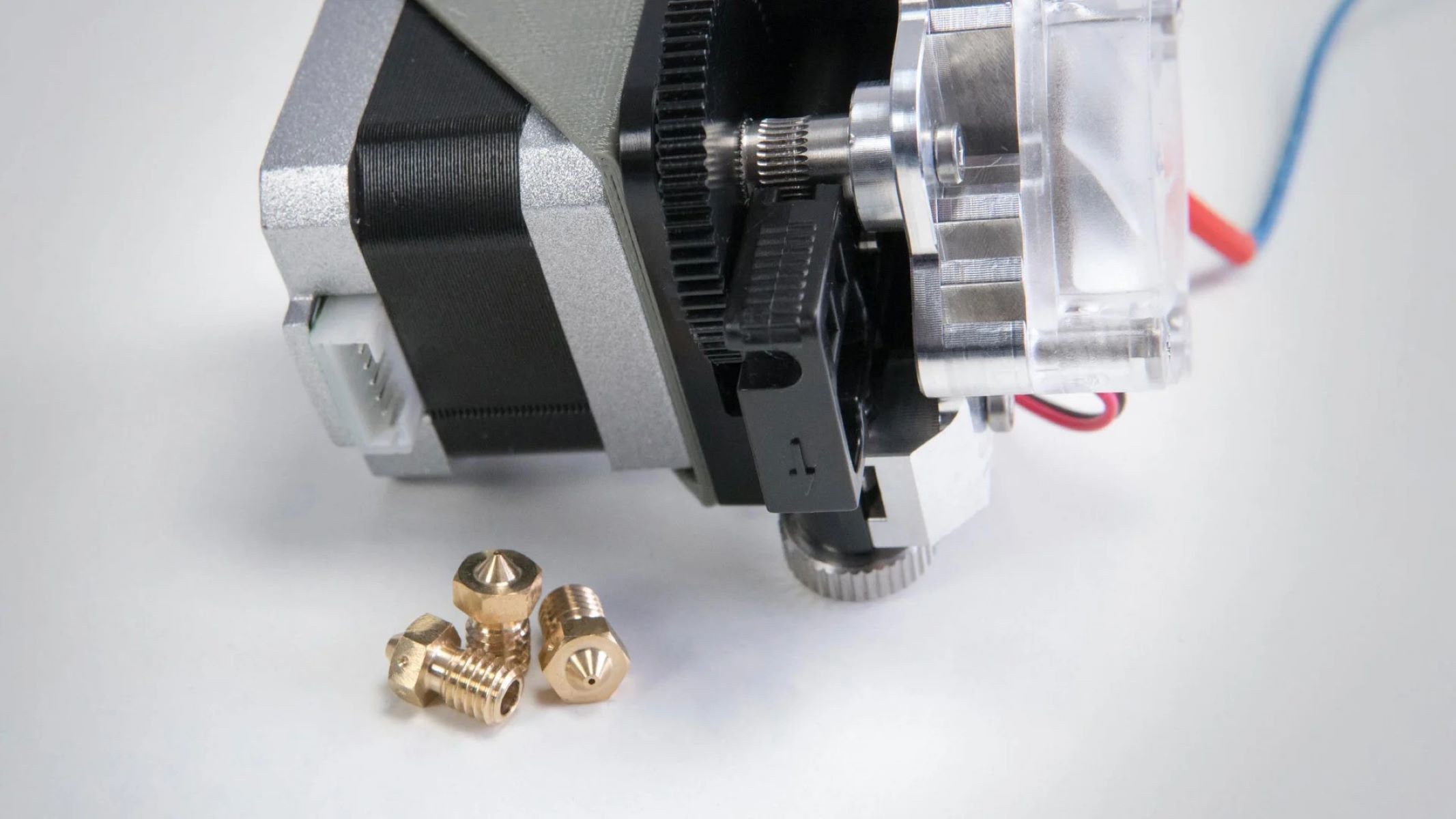

Nozzle Clogs

Nozzle clogs are a common source of frustration in 3D printing, often leading to failed prints and interrupted workflows. Understanding the causes of nozzle clogs and how to effectively address them is crucial for maintaining smooth and reliable printing processes. Let’s delve into the common issues related to nozzle clogs and explore strategies for resolving them.

1. Filament Contaminants: Contaminants in the filament, such as dust, debris, or foreign particles, can lead to nozzle clogs. It’s essential to ensure that the filament is clean and free from impurities before loading it into the printer.

2. Heat Creep: Heat creep occurs when heat travels beyond the heat break in the hot end, causing filament to soften and clog the nozzle. Proper cooling and ventilation around the hot end can help mitigate heat creep and prevent nozzle clogs.

3. Partial Cold Pulls: Incomplete cold pulls during filament changes can leave residue in the nozzle, contributing to clogs. Performing thorough and effective cold pulls when swapping filaments can help prevent residual buildup and maintain nozzle integrity.

4. Print Speed and Retraction Settings: Inappropriate print speeds and retraction settings can contribute to filament buildup and clogs in the nozzle. Fine-tuning these settings to minimize filament stress and buildup can help prevent nozzle clogs during printing.

5. Nozzle Diameter and Material Compatibility: Mismatched filament diameters and materials with incompatible melting temperatures can lead to nozzle clogs. Ensuring that the filament and nozzle specifications align can help prevent material-related clogging issues.

By addressing these common causes of nozzle clogs and implementing proactive maintenance and printing practices, you can minimize the risk of interruptions and achieve consistent, high-quality prints. Now, let’s explore another critical aspect of 3D printing: software and firmware problems.

Software and Firmware Problems

Software and firmware play a pivotal role in the 3D printing process, facilitating the translation of digital designs into physical objects. However, issues related to software and firmware can significantly impact the printing experience. Let’s explore some common problems in this domain and strategies for resolving them.

1. Slicing Errors: Inaccurate slicing settings or software errors can lead to flawed G-code generation, resulting in print defects and inconsistencies. Ensuring that slicing parameters are correctly configured and utilizing reliable slicing software can help mitigate slicing-related issues.

2. Firmware Compatibility: Incompatible or outdated firmware versions can lead to communication errors and operational glitches. Keeping firmware up to date and ensuring compatibility with the printer’s hardware components is essential for stable and reliable printing performance.

3. Connectivity and Communication Issues: Unstable USB connections, communication timeouts, or software-to-hardware communication failures can disrupt print jobs and lead to print failures. Utilizing reliable connectivity methods and troubleshooting communication issues can help maintain seamless printing operations.

4. Firmware Calibration and Configuration: Incorrect firmware settings and calibration parameters can lead to erratic printer behavior and suboptimal print quality. Thoroughly reviewing and adjusting firmware configurations based on the printer’s specifications is crucial for achieving consistent and accurate printing results.

5. Software Bugs and Glitches: Software bugs and glitches can manifest as unexpected errors or malfunctions during the printing process. Staying updated with software patches and utilizing reputable, well-maintained software can help minimize the impact of software-related issues on 3D printing workflows.

By addressing these common software and firmware challenges and adopting best practices for software and firmware management, you can enhance the reliability and performance of your 3D printing endeavors. Now, let’s reflect on the insights gained and conclude our exploration of troubleshooting 3D printing issues.

Conclusion

Congratulations! You’ve embarked on a journey to unravel the mysteries of 3D printing malfunctions and equip yourself with the knowledge to overcome common challenges. By delving into the intricacies of filament problems, bed leveling issues, nozzle clogs, and software and firmware problems, you’ve gained valuable insights into troubleshooting and optimizing the 3D printing process.

As you navigate the world of 3D printing, it’s essential to approach challenges with a curious and resilient mindset. Embracing the iterative nature of troubleshooting and problem-solving in 3D printing can lead to valuable learning experiences and a deeper understanding of the technology’s nuances.

Remember, successful 3D printing is a harmonious convergence of art, science, and technology. It requires attention to detail, patience, and a willingness to adapt and refine your approach. By integrating the knowledge gained from this guide into your 3D printing endeavors, you’re poised to overcome obstacles and unleash the full potential of your 3D printer.

Whether you’re crafting intricate prototypes, personalized gifts, or functional components, the ability to troubleshoot and optimize your 3D printing process empowers you to bring your creative visions to life with precision and confidence.

As you continue your 3D printing journey, stay curious, stay resilient, and embrace the spirit of exploration. Each print, whether flawless or flawed, presents an opportunity to learn and refine your craft. With the right mindset and knowledge at your disposal, you’re well-equipped to conquer any challenges that may arise in your 3D printing adventures.

Now, armed with a deeper understanding of common 3D printing issues and their solutions, you’re ready to unleash your creativity and innovation through the mesmerizing world of 3D printing. Happy printing!

Frequently Asked Questions about Why Does My 3D Printer Keep Messing Up

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Does My 3D Printer Keep Messing Up”