Articles

How Far To Strip Electrical Wire

Modified: May 6, 2024

Discover the distance required to strip electrical wire with our informative articles. Learn the proper techniques for safely removing insulation from different wire gauges.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electrical wires are the backbone of our modern world, powering everything from our homes to our workplaces. Whether you are a DIY enthusiast or a professional electrician, knowing how to strip electrical wire is a fundamental skill that can come in handy in a variety of situations.

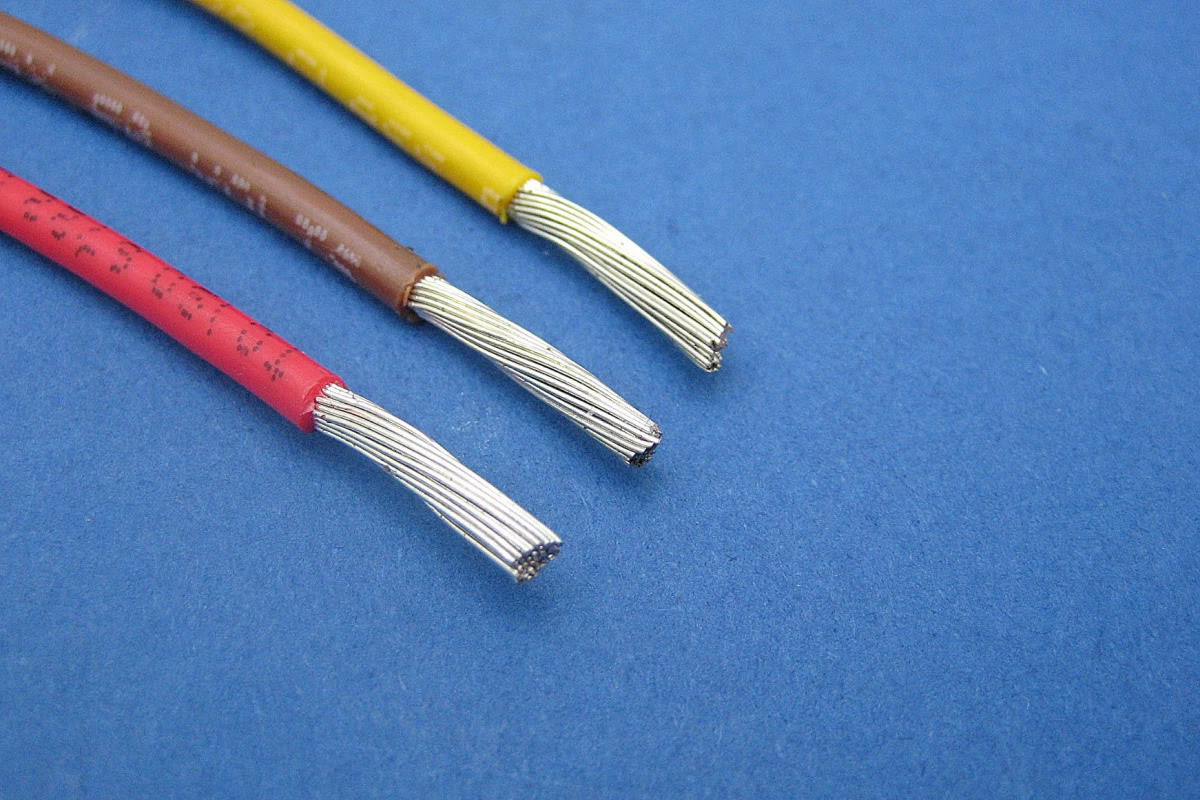

Stripping electrical wire involves removing the outer insulation to expose the copper or aluminum conductor inside. This process is necessary when connecting wires, making repairs, or installing new electrical components. However, doing it properly is crucial to ensure safety and maintain the integrity of the wire.

In this article, we will delve into the art of wire stripping, providing you with step-by-step instructions, essential safety precautions, and valuable tips to help you strip electrical wire like a pro.

Whether you’re a seasoned pro or just starting out, this comprehensive guide will equip you with the knowledge and skills needed to tackle any wire stripping task with confidence and precision. So, let’s dive in and learn how to strip electrical wire like a pro!

Key Takeaways:

- Safety is paramount when stripping electrical wire. Always turn off the power, wear protective gear, and inspect wires for damage before beginning the process.

- Understanding wire gauge, insulation type, and proper techniques are essential for successful wire stripping. Practice precision and follow safety guidelines for reliable electrical connections.

Safety Precautions

Before we delve into the process of stripping electrical wire, it is essential to prioritize safety. Working with electricity can be dangerous, so follow these safety precautions to minimize the risk of accidents or injuries:

- Turn off the power: Before working on any electrical wiring, always ensure that the power is turned off at the breaker or fuse box. This will prevent the risk of electric shock.

- Wear protective gear: Always wear safety goggles and gloves to protect yourself from any potential hazards during the wire stripping process, such as flying debris or accidental contact with live wires.

- Inspect the wire: Before stripping any wire, inspect it for any signs of damage or wear. If you notice any frayed or damaged insulation, avoid stripping it and replace the wire instead.

- Use insulated tools: When handling wires, make sure to use properly insulated tools. This reduces the risk of accidental contact with live wires and reduces the chance of electrical shorts.

- Work in a well-ventilated area: If you are working with older electrical wires, there may be a risk of exposure to harmful substances such as lead or asbestos. Ensure that you are working in a well-ventilated area to minimize any potential health risks.

- Keep a fire extinguisher nearby: In case of an accidental fire, always have a fire extinguisher readily available. Make sure that you know how to use it effectively.

- Never work alone: Whenever possible, work with a partner or have someone nearby who is aware of your work and can assist in case of an emergency.

Remember, safety should always be the top priority when working with electrical wiring. Following these precautions will reduce the risk of accidents and ensure a successful and secure wire stripping process.

Tools and Materials Needed

Before you begin the process of stripping electrical wire, it’s important to gather all the necessary tools and materials. Having the right equipment on hand will make the task easier and more efficient. Here are the essential tools and materials you’ll need for wire stripping:

- Wire Stripper: A wire stripper is a specialized tool designed to strip off the insulation from electrical wires. It typically has multiple size options to accommodate different wire gauges. Look for a wire stripper with sharp blades for clean and precise cuts.

- Wire Cutters: Wire cutters are used to cut the wire to the desired length. They are different from wire strippers as they have a flat cutting edge rather than a cutting notch.

- Pliers: Pliers are handy for gripping the wire while stripping the insulation. They can also be used to bend wire ends or make adjustments to the wire during installation.

- Marker or Tape: Having a marker or tape on hand is useful for labeling the wires. This makes it easier to identify the purpose or destination of each wire when working on complex wiring projects.

- Wire Brush or Sandpaper: A wire brush or sandpaper can be used to clean the conductive material of the wire, ensuring optimal contact when connecting or terminating the wire.

- Safety Gear: As mentioned in the safety precautions section, it’s essential to wear safety goggles and gloves to protect yourself during the wire stripping process.

- Container: You’ll need a container or a designated space to collect the stripped insulation. This makes it easier to keep your workspace clean and organized.

Once you have gathered all these tools and materials, you’re ready to start stripping electrical wire. Remember to always handle the tools with care and follow the instructions provided by the manufacturer.

Understanding Wire Stripping

Before diving into the process of stripping electrical wire, it’s important to have a clear understanding of what wire stripping entails. Wire stripping is the process of removing the outer insulation or coating from electrical wires to expose the conductive material inside, which is typically copper or aluminum.

The purpose of wire stripping is to prepare the wire for various electrical connections, such as joining wires together or connecting them to terminals, switches, or outlets. By removing the insulation, you expose a section of the conductive material, allowing for a secure and reliable electrical connection.

The insulation on electrical wires serves to protect the conductive material from damage, prevent short circuits, and provide electrical insulation. However, there are instances where the insulation needs to be stripped off to facilitate proper electrical connections or repairs.

Wire stripping is commonly performed when:

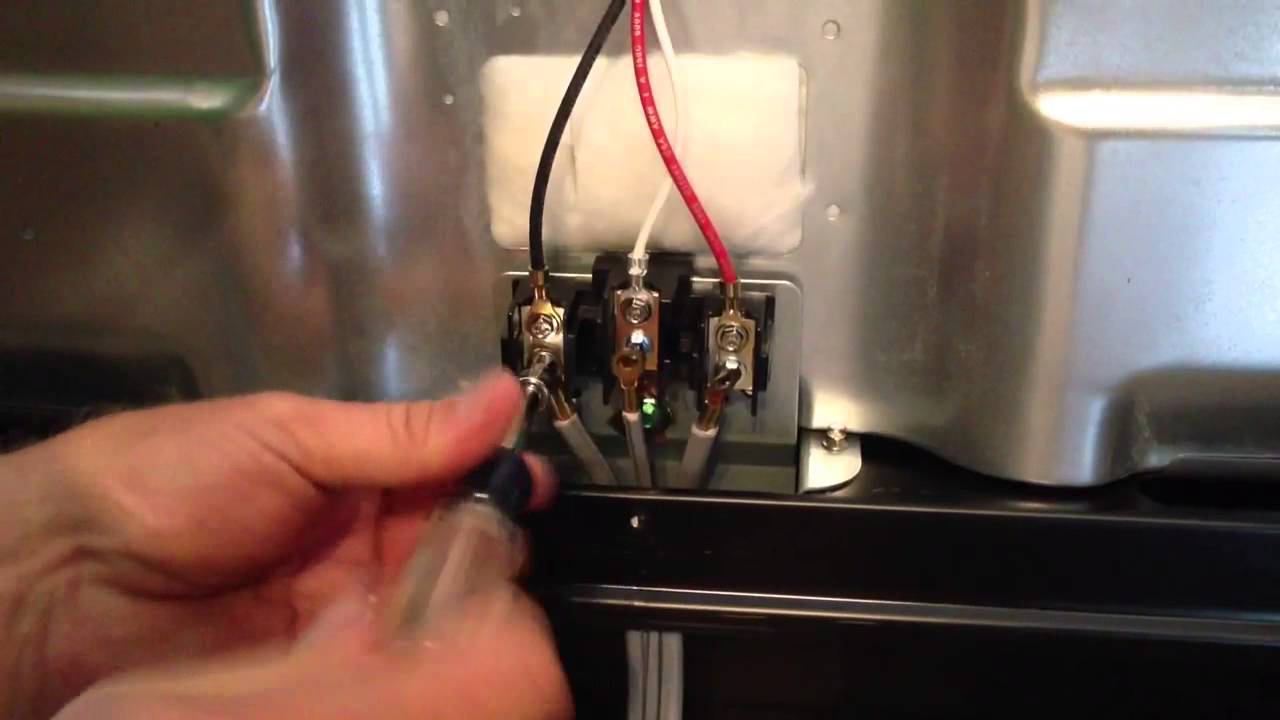

- Connecting wires: When connecting two or more wires together, the insulation needs to be removed so that the conductive material can make direct contact, ensuring a solid electrical connection.

- Terminating wires: When terminating wires to switches, outlets, or terminals, the insulation needs to be stripped off to expose the conductive material, allowing for proper connection and conductivity.

- Repairing damaged wires: If an electrical wire has a damaged or frayed section of insulation, it is necessary to strip off the damaged portion and replace it with a new section of insulation.

Understanding the need for wire stripping and the situations in which it’s necessary will enable you to approach the process with confidence and precision. Properly stripped wires result in secure connections, enhanced conductivity, and a safer electrical system overall.

Factors to Consider

When it comes to wire stripping, there are several key factors to consider to ensure a successful and efficient process. Taking these factors into account will help you achieve clean and precise wire stripping results:

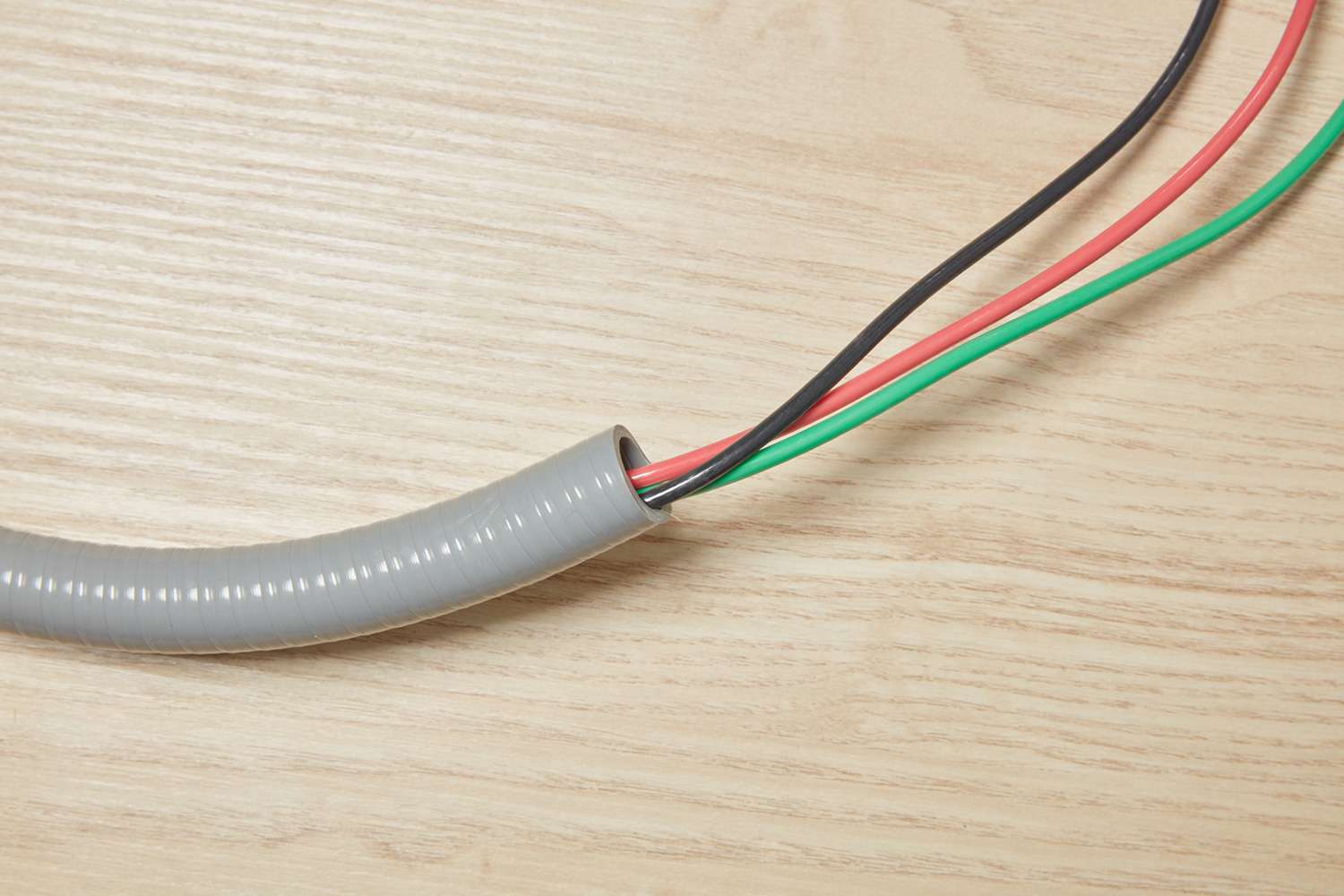

- Wire Gauge: The wire gauge refers to the thickness or diameter of the wire. Different wire gauges require different stripping techniques and tools. It is important to match the appropriate wire stripper size to the wire gauge being stripped to avoid damaging the wire.

- Insulation Type: Electrical wires can have different types of insulation, such as PVC, rubber, or Teflon. Understanding the type of insulation is crucial since different insulation materials require different stripping techniques. For example, PVC insulation is commonly stripped with a straight blade, while rubber insulation may require a scoring or slicing method.

- Wire Length: The length of the wire can also impact the wire stripping process. If you are working with a long wire, it may be more convenient to strip it in sections rather than attempting to strip the entire length at once.

- Wire Condition: Inspect the condition of the wire before stripping it. Look for any signs of damage, such as frayed or brittle insulation. If the wire is damaged, it’s best to replace it rather than attempting to strip it.

- Tightness of the Grip: When using a wire stripper, ensure that the tool’s grip on the insulation is firm but not too tight. If the grip is too loose, it may result in incomplete or uneven stripping. If the grip is too tight, it could damage the conductive material beneath the insulation.

- Accuracy: Accuracy plays a vital role in wire stripping. Make sure to position the wire stripper correctly and apply consistent pressure to obtain a clean and precise strip. Avoid angling the stripper or applying excessive force during the cutting process, as this can lead to uneven or damaged cuts.

Considering these factors will help you approach wire stripping with confidence and ensure that you achieve the desired results: clean, precise, and intact stripped wires ready for installation or connection.

When stripping electrical wire, use a wire stripper tool to ensure you remove just enough insulation without damaging the conductors. This will help maintain the integrity of the wire and ensure a secure connection.

Read more: How To Wire LED Strips

When to Strip Electrical Wire

Knowing when to strip electrical wire is crucial to ensure proper installation, repairs, or upgrades in electrical systems. Here are the common situations when stripping electrical wire is necessary:

- Installation of electrical components: When installing switches, outlets, or other electrical components, it is often necessary to strip the wire to expose the conductive material for proper connection. This allows for a secure and reliable electrical connection.

- Repairing damaged insulation: If the insulation on an electrical wire is damaged, it is important to strip off the damaged section and replace it with new insulation. This ensures the integrity and safety of the electrical system.

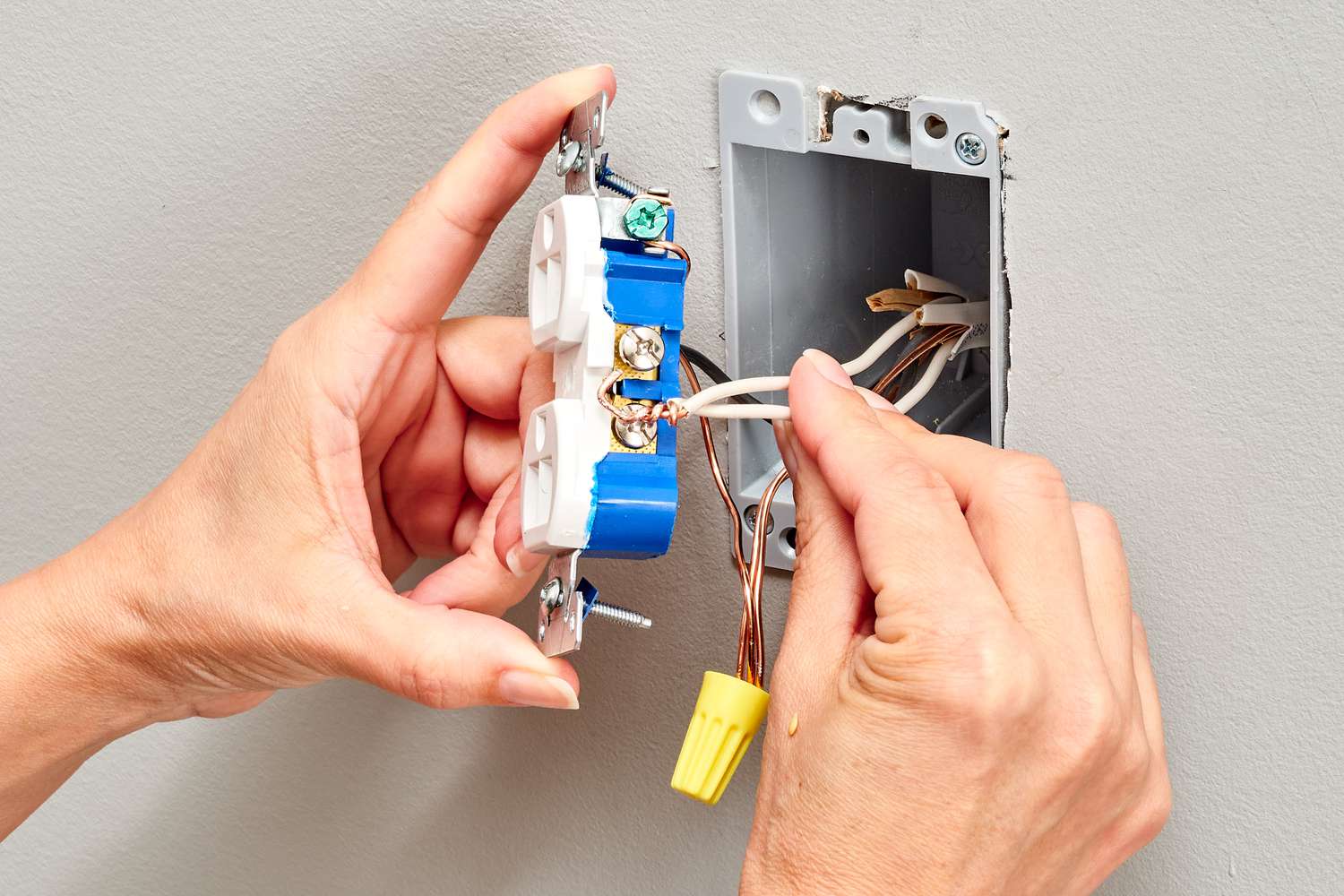

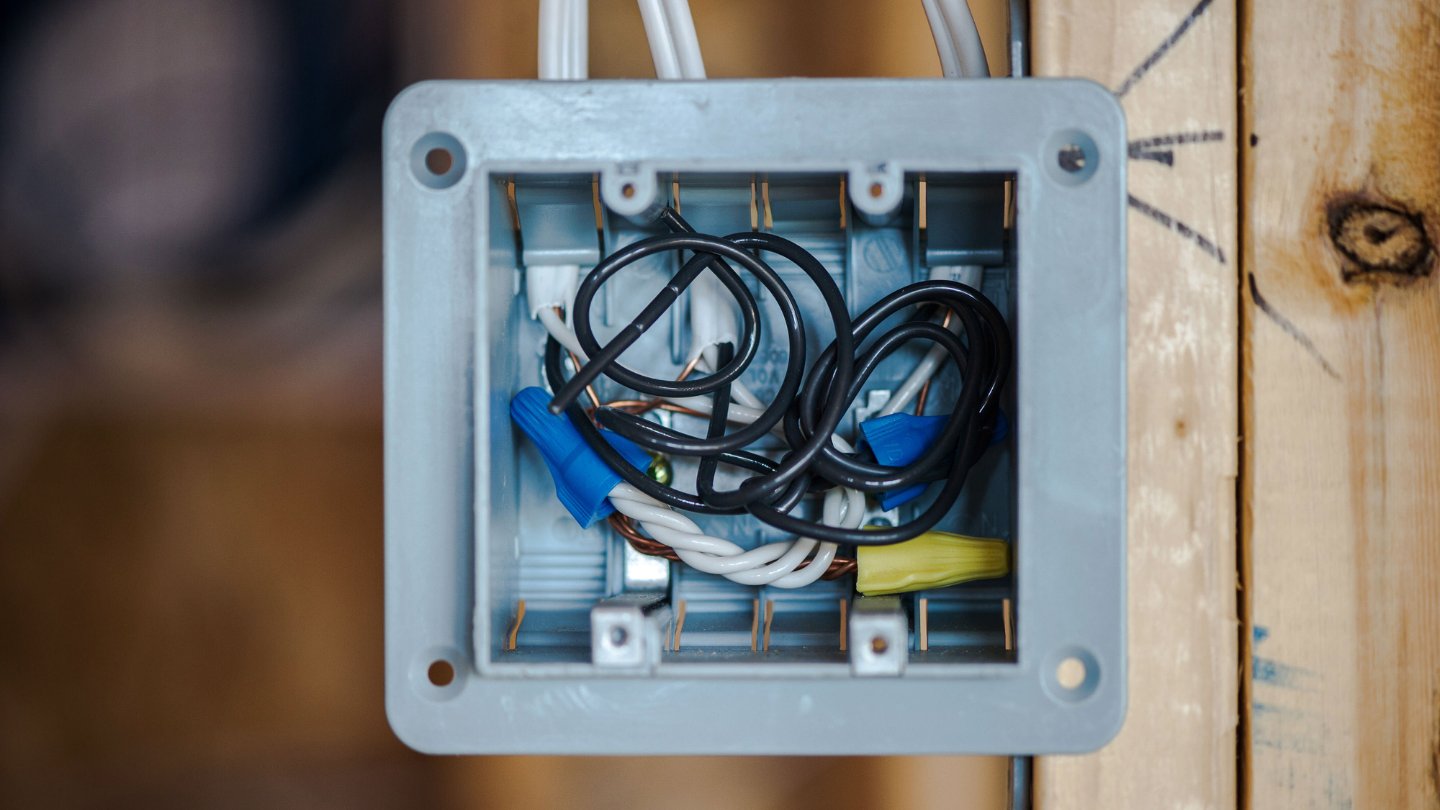

- Creating wire connections: When connecting multiple wires together, whether in junction boxes or during electrical installations, stripping the insulation is required to expose the conductive material. This allows for a direct and secure connection between the wires.

- Testing or troubleshooting electrical circuits: Stripping the insulation can be necessary when testing or troubleshooting electrical circuits. It allows for access to the conductive material, enabling accurate measurements or repairing faulty connections.

- Upgrading or modifying electrical systems: When making changes or upgrades to an existing electrical system, it may be necessary to strip wires to accommodate new connections or components. This ensures compatibility and proper functionality.

It’s important to note that not all electrical wires require stripping. Some wires come with pre-stripped ends or connectors, eliminating the need for additional stripping. Additionally, certain types of connectors or terminals may require specific stripping lengths or techniques. Always refer to the manufacturer’s instructions or guidelines for proper stripping procedures when working with specific components.

By understanding when to strip electrical wire, you can ensure proper connections, repairs, and upgrades in your electrical projects, promoting safety and reliability in your electrical system.

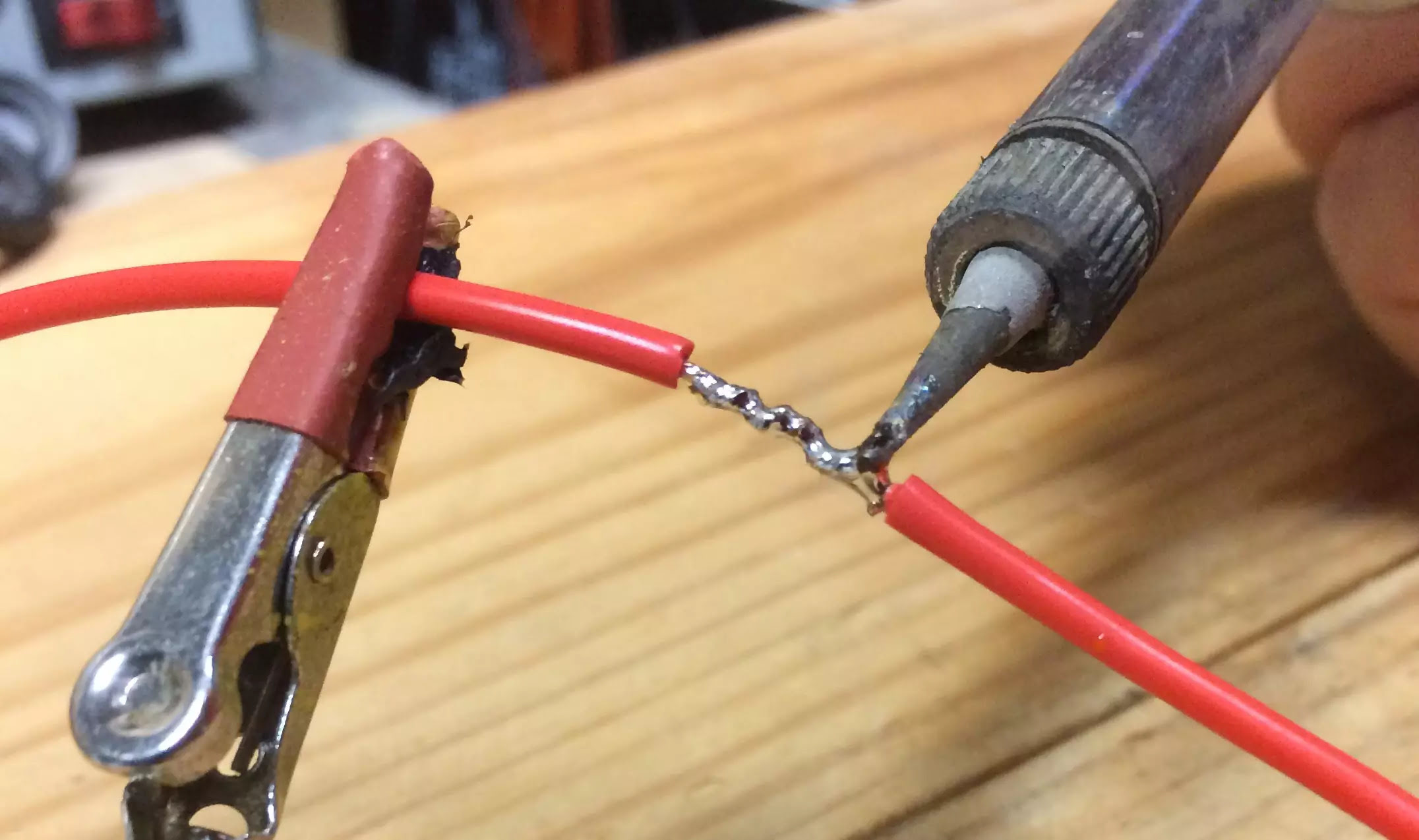

How to Strip Electrical Wire

Stripping electrical wire may seem daunting at first, but with the right technique and tools, it can be a straightforward process. Follow these step-by-step instructions to strip electrical wire effectively:

- Gather the necessary tools: Before starting, ensure you have the appropriate wire stripper that matches the wire gauge you are working with. Also, have wire cutters, pliers, and safety gear ready.

- Secure the wire: Hold the wire firmly in one hand, ensuring it doesn’t slip or move during the stripping process.

- Position the wire stripper: Place the wire stripper’s cutting blades around the insulation, adjusting the stripper’s size if necessary. Make sure the blades are in the correct position for a clean cut.

- Apply moderate pressure: Squeeze the handles of the wire stripper gently, applying moderate pressure on the insulation. Be careful not to squeeze too hard to avoid damaging the conductive material beneath the insulation.

- Rotate the stripper: While maintaining pressure on the handles, rotate the wire stripper around the circumference of the wire. This will score the insulation, making it easier to remove.

- Complete the rotation: Once you have rotated the wire stripper around the wire, release the pressure on the handles and separate the stripper from the wire.

- Remove the insulation: Use your fingers or pliers to grip the scored section of the insulation and gently pull it away from the wire. Take care not to pull too forcefully, as it may damage the conductive material.

- Inspect the strip: After removing the insulation, carefully inspect the stripped section of the wire. Ensure that the conductive material is exposed without any damage or nicking.

- Trim the wire if necessary: If there are any uneven or damaged sections of the conductor, use wire cutters to trim them. This will ensure a clean and smooth end for proper connections.

Practice is key when it comes to wire stripping. Take your time, be patient, and strive for clean and precise stripping. With experience, you’ll develop the knack for stripping wires efficiently and effectively.

Remember, always follow safety guidelines and precautions when handling electrical wires, and consult the manufacturer’s instructions or guidelines for specific wire stripping requirements.

Techniques for Different Wire Gauges

Wire stripping techniques may vary depending on the gauge or thickness of the wire. Different wire gauges require different levels of precision and methods to ensure proper stripping. Here are some techniques to keep in mind when working with different wire gauges:

- Thin gauge wire (e.g., 20-28 AWG): For thin gauge wires, precision is crucial. Use a wire stripper with smaller gauge settings and be gentle during the stripping process. Apply minimal pressure to avoid damaging the wire and ensure a clean strip.

- Medium gauge wire (e.g., 16-18 AWG): Medium gauge wires are more forgiving, but precision is still important. Adjust your wire stripper to accommodate the specific gauge and apply moderate pressure while rotating it around the wire. Take care to avoid cutting into the conductor or leaving behind any jagged edges.

- Thick gauge wire (e.g., 12-14 AWG): Thick gauge wires require more force to strip. Ensure that your wire stripper is properly adjusted for the gauge and apply sufficient pressure to score the insulation. Take care not to exert too much force that may damage the conductive material. Consider using pliers to grip and remove the insulation if needed.

It’s essential to have wire strippers with the appropriate size settings to match the gauge of the wire you’re working with. Using the wrong size can lead to uneven or damaged cuts, compromising the integrity of the wire.

Additionally, it’s important to practice proper techniques and develop a feel for each wire gauge. As you gain experience, you’ll become more comfortable and adept at stripping wires of various sizes.

Remember to refer to the wire gauge markings on the wire itself or use a wire gauge measurement tool to accurately determine the gauge before selecting the appropriate stripping technique. Being mindful of the wire gauge and utilizing the right technique will result in clean, precise, and reliable wire stripping.

Common Mistakes to Avoid

Stripping electrical wire requires precision and care to ensure proper connections and avoid potential hazards. Here are some common mistakes to avoid when stripping electrical wire:

- Using the wrong tool: Using the wrong wire stripping tool for the wire gauge can lead to uneven or damaged cuts. Make sure to select a wire stripper that matches the gauge of the wire you are working with.

- Applying too much force: Applying excessive force when stripping the wire can damage the conductive material or cause it to break. Apply moderate pressure to score the insulation without cutting into the wire.

- Neglecting safety precautions: Always prioritize safety when working with electricity. Wear protective gear, turn off the power, and work in a well-ventilated area to minimize risks.

- Incorrect gauge selection: Using the wrong size setting on the wire stripper can lead to inaccurate or incomplete cuts. Double-check the wire gauge and adjust the stripper accordingly.

- Incorrect stripping length: Stripping too much or too little insulation can lead to connection issues or potential short circuits. Measure and strip the proper length of insulation according to the specific requirements of the application.

- Damaging the conductive material: Being too aggressive during the stripping process can damage or nick the conductive material, compromising the integrity of the wire. Handle the wire and stripping tool with care to avoid damaging the conductor.

- Not inspecting the stripped wire: After stripping the wire, thoroughly inspect the exposed conductor to ensure it is intact, without any damage or sharp edges. This will help prevent potential hazards and issues down the line.

- Not practicing proper wire management: Proper wire management is essential for safety and organization. Dispose of stripped insulation properly, keep the workspace clean, and securely fasten and label wires to avoid confusion or potential accidents.

By avoiding these common mistakes, you’ll be able to strip electrical wire effectively and safely. Always take your time, double-check your work, and follow best practices to achieve successful wire stripping results.

Read more: What Is 4 Wire Electrical Wire

Conclusion

Stripping electrical wire is a fundamental skill for anyone working with electrical systems, whether you’re a DIY enthusiast or a professional electrician. Understanding the process and following the right techniques is crucial to ensure proper connections, repairs, and upgrades while maintaining safety and integrity.

In this article, we have covered the essentials of wire stripping, including safety precautions, the tools and materials needed, techniques for different wire gauges, and common mistakes to avoid. By prioritizing safety, gathering the necessary tools, understanding wire gauge requirements, and applying proper stripping techniques, you can strip electrical wire like a pro.

Always remember to turn off the power, wear protective gear, and work in a well-ventilated area. Choose the right wire stripper for the gauge you’re working with, apply the appropriate amount of pressure during the stripping process, and inspect the stripped wire for any damage or sharp edges. Proper wire management and attention to detail will contribute to a successful and safe wiring project.

Whether you’re installing new electrical components, making repairs, or troubleshooting electrical circuits, the ability to strip electrical wire accurately and efficiently is invaluable. With practice and experience, you will develop your skills and gain confidence in this essential task.

By following the guidelines and techniques outlined in this article, you are now equipped with the knowledge to take on any wire stripping project. So go ahead, strip those wires with precision, and ensure the reliability and safety of your electrical connections.

Ready to tackle more DIY electrical projects? If you're planning to extend your workshop or need power in your garage, our guide on how to run overhead electrical wiring will prove invaluable. Additionally, stripping wires efficiently remains key to successful electrical work. Don't miss our review of the top wire stripping tools set to dominate in 2024, ensuring you're well-equipped for any task.

Frequently Asked Questions about How Far To Strip Electrical Wire

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Far To Strip Electrical Wire”