Articles

How To Wire Electrical Box

Modified: January 6, 2024

Discover the best articles on how to wire an electrical box and learn step-by-step techniques for an efficient installation. Improve your electrical skills with our informative content.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Wiring an electrical box can seem like a daunting task, especially if you’re not familiar with electrical work. However, with the right tools, materials, and safety precautions, it’s a task that you can tackle confidently. Whether you’re replacing an old electrical box or installing a new one, this comprehensive guide will walk you through the step-by-step process, ensuring that you complete the job safely and effectively.

Before we dive into the specifics, it’s important to note that electrical work should only be performed by individuals with proper training and experience. If you’re not comfortable working with electricity, it’s always best to hire a licensed electrician to handle the job. Safety should be your top priority when working with electrical components, as even a small mistake can have serious consequences.

In this article, we’ll cover everything you need to know to successfully wire an electrical box. From choosing the right materials to connecting the wires correctly, we’ll guide you through each step of the process. By the end, you’ll have the knowledge and confidence to wire electrical boxes like a pro.

Before we begin, let’s take a brief look at the tools and materials you’ll need for the job.

Key Takeaways:

- Safety First

When wiring an electrical box, prioritize safety by turning off the power, wearing protective gear, and securing connections. Following safety precautions minimizes the risk of accidents and ensures a successful installation. - Proper Planning and Execution

From choosing the right materials to testing the electrical connections, meticulous planning and execution are crucial for wiring an electrical box. Attention to detail and adherence to local regulations lead to a safe and functional electrical system.

Read more: How To Wire A Shallow Electrical Box

Tools and Materials Needed

Before you start wiring an electrical box, gather the necessary tools and materials to ensure a smooth and efficient installation process. Here’s a list of what you’ll need:

Tools:

- Wire stripper

- Wire cutter

- Screwdriver (flathead and Phillips)

- Needle-nose pliers

- Voltage tester

- Drill (with appropriate drill bits)

- Tape measure

- Pencil or marker

- Level

Materials:

- Electrical box

- Electrical wire (appropriate gauge for the circuit)

- Wire connectors

- Outlet or switch

- Cover plate

- Screws

These tools and materials are essential for the proper installation of an electrical box. Make sure you have everything on hand before you begin the wiring process to avoid delays or interruptions.

Before we move on, it’s important to highlight the significance of safety precautions when working with electricity.

Safety Precautions

When it comes to working with electricity, safety should always be your top priority. Remember, electricity can be dangerous if not handled properly. Follow these safety precautions to minimize the risk of electrical accidents:

Read more: How To Count Wires In An Electrical Box

1. Shut Off the Power:

Before you start working on the electrical box, turn off the power to the circuit at the main electrical panel. This will prevent any electrical shocks or incidents while you’re working. Use a voltage tester to double-check that the power is off before starting any work.

2. Wear Protective Gear:

Protect yourself by wearing proper safety gear, including safety glasses, gloves, and non-conductive footwear. This will protect you from any potential electrical hazards.

3. Work in a Dry Environment:

Make sure the area you’re working in is dry. Avoid working in damp or wet conditions, as water can conduct electricity and increase the risk of electric shock.

4. Use Insulated Tools:

Only use insulated tools specifically designed for electrical work. Insulated tools have rubber or plastic handle covers that provide an extra layer of protection against electrical shocks.

Read more: How To Run Electrical Wire From Breaker Box

5. Avoid Overloading the Circuit:

Each circuit has a specific amp rating, and it’s essential to avoid overloading it. Check the amp rating of the circuit and make sure the total wattage of the devices connected to it does not exceed that limit.

6. Double-Check Connections:

Before turning on the power, double-check all the connections to ensure they are secure and properly insulated. Loose connections can cause electrical arcing, leading to overheating and potential fire hazards.

7. Seek Professional Help if Needed:

If you are unsure about any step in the process or feel uncomfortable working with electricity, it’s best to contact a licensed electrician. They have the knowledge and expertise to ensure the job is done safely and accurately.

By following these safety precautions, you can minimize the risk of accidents and ensure a safe working environment. Now that we’ve covered the safety aspects, let’s move on to the step-by-step process of wiring an electrical box.

Step 1: Turn Off the Power

Before you begin wiring an electrical box, it is crucial to turn off the power to the circuit to ensure your safety. Here’s how you can do it:

- Locate the main electrical panel in your home. This panel contains the circuit breakers or fuses that control the power supply to various circuits.

- Identify the circuit breaker that corresponds to the circuit you’ll be working on. If you’re unsure, you can use a voltage tester to check which circuit is live.

- Once you’ve identified the correct circuit breaker, switch it to the “Off” position. This will cut off the power supply to the circuit.

- Use a voltage tester to verify that the power to the circuit is indeed off. Test the wires or outlets connected to the circuit to ensure they are not live.

Turning off the power is a crucial step that ensures your safety while working with electrical components. It prevents the risk of electric shock and other accidents. Remember, it’s always better to be safe than sorry.

Now that you’ve turned off the power, you can proceed with the next steps of wiring the electrical box.

Read more: What Is 4 Wire Electrical Wire

Step 2: Choose the Right Box

Choosing the right electrical box is essential for a successful wiring installation. The box not only houses the electrical connections but also provides protection and support for the wiring. Here’s what you need to consider when selecting an electrical box:

Size and Type:

Determine the appropriate size and type of electrical box for your specific needs. The size of the box depends on the number and size of wires, as well as the devices (outlets, switches, etc.) that will be installed in it. Common box types include octagon, square, and rectangular shapes.

Material and Construction:

Choose a box made of sturdy and durable material, such as metal or plastic. Metal boxes are more robust and provide better protection against impact or fire, while plastic boxes are lightweight and resistant to corrosion.

Mounting Options:

Consider the mounting options available for the electrical box. Whether it’s a surface-mounted box or a recessed box (such as in-wall or in-ceiling), ensure that it suits your installation requirements and provides a secure and stable attachment point.

Read more: How To Trace An Electrical Wire

Accessibility:

Ensure that the electrical box allows easy access to the wiring connections. Accessibility is essential for future maintenance or repairs. Some boxes have removable or hinged covers, while others have access holes or knockouts for additional wiring.

Regulatory Compliance:

Ensure that the electrical box complies with local building codes and regulations. It should meet the required safety standards, have appropriate grounding provisions, and be labeled with relevant certification marks.

Take your time to choose the right electrical box for your specific wiring project. Getting the correct box will ensure a proper and safe installation.

Now that you have selected the right box, we can move on to the next step: selecting the proper wire.

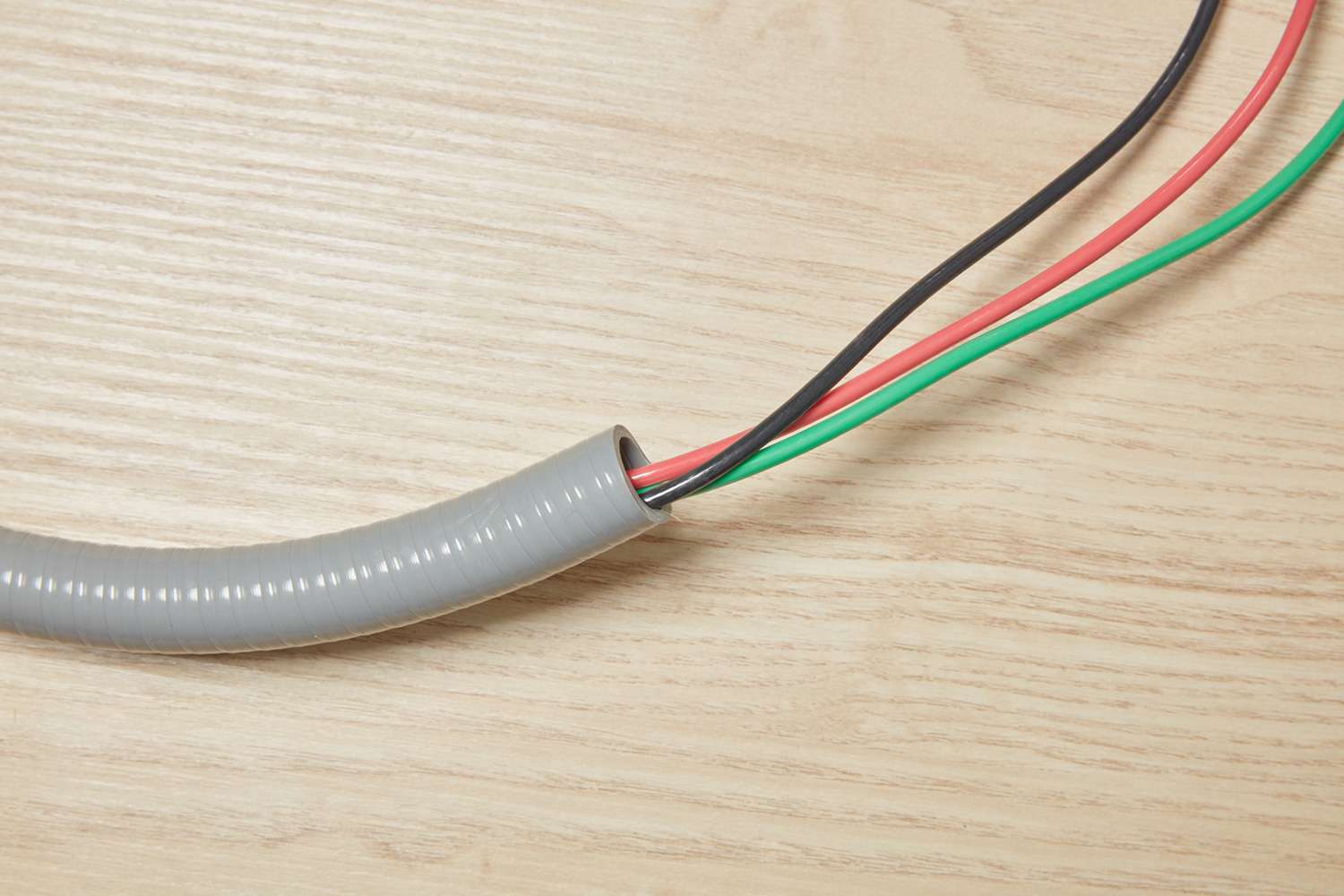

Step 3: Select the Proper Wire

Selecting the proper wire is essential for ensuring a safe and efficient electrical installation. The type and size of wire you choose depend on the electrical load, circuit length, and local building codes. Here’s what you need to consider when selecting the wire:

Wire Type:

There are various wire types available, including copper and aluminum. Copper wires are the most common choice due to their excellent conductivity and durability. Aluminum wires are cheaper but have lower conductivity and may require special connectors or treatments.

Read more: How To Wire An Electric Cooktop

Wire Size:

Wire size is determined by the wire gauge (AWG), which indicates the diameter of the wire. The larger the wire gauge number, the smaller the wire. The size of wire you need depends on the electrical load of the circuit. Consult local building codes or an electrician to determine the appropriate wire size for your project.

Circuit Length:

Consider the distance between the electrical box and the power source. Longer circuit lengths may require thicker wires to compensate for voltage drop, ensuring that sufficient power reaches the desired destination.

Wire Insulation:

Choose wire with proper insulation for the specific application. Insulation protects the wire from damage, moisture, and heat. Common insulation types include non-metallic (NM) sheathed cable for general residential wiring and THHN/THWN for more demanding applications.

Labeling and Certification:

Ensure that the wire is labeled and certified for the specific use, such as residential or commercial applications. Look for certification marks like UL (Underwriters Laboratories) or CSA (Canadian Standards Association) to ensure compliance with safety standards.

Consult with an electrician or refer to local building codes to determine the appropriate wire type and size for your specific electrical box installation. Selecting the proper wire is crucial for a safe and reliable electrical system.

Now that you have chosen the proper wire, we can move on to planning the wiring layout.

Step 4: Plan the Wiring Layout

Planning the wiring layout is a crucial step in ensuring an organized and efficient electrical installation. Taking the time to plan out the wiring layout will help you determine the optimal routing of wires and ensure that you have all the necessary materials and tools before you begin. Here are the key considerations for planning your wiring layout:

Identify Circuits:

Start by identifying the circuits that will run through the electrical box. Each circuit typically powers specific outlets, switches, or appliances. Identify the starting point (e.g., the main electrical panel) and the endpoints (e.g., outlets or switches) for each circuit.

Determine Wire Routes:

Map out the most direct and efficient routes for the wires. Consider factors such as wall structure, obstructions, and ease of access. It’s best to run wires through wall cavities whenever possible to hide them from view.

Separate Circuits:

Avoid running multiple circuits in the same electrical box unless absolutely necessary. Separate circuits help prevent circuit overloading and make troubleshooting and maintenance easier in the future.

Read more: How To Cap An Electrical Wire

Consider Future Needs:

Anticipate any future electrical needs or changes when planning the wiring layout. Leave extra space in the electrical box and provide additional wiring routes or conduits for potential additions or modifications.

Label Connections:

Labeling connections is essential for easy identification and troubleshooting down the line. Use labels or color-coding to differentiate wires for each circuit and mark the purpose (e.g., “lighting,” “kitchen outlets”) of each connection.

Remember to consult local building codes and regulations when planning the wiring layout. It’s recommended to seek professional advice if you are unsure or have complex wiring requirements.

With a well-thought-out wiring layout plan in place, you will be ready to proceed to the next step: removing the old box (if applicable) or mounting the new box.

Step 5: Remove the Old Box (If Applicable)

If you’re replacing an existing electrical box, you’ll need to remove the old box before installing the new one. Removing the old box requires careful attention to detail to ensure a smooth transition. Here’s how you can remove the old box:

- Turn off the power supply to the circuit at the main electrical panel. Double-check with a voltage tester to ensure that the power is indeed off.

- Remove the cover plate and screws from the old box.

- Detach the wires from the old box by unscrewing the wire connectors or loosening the terminal screws. Take note of the wire connections or take a picture for reference when connecting the new box.

- Using a screwdriver, remove the screws or nails that secure the old box to the wall or ceiling. Carefully pull the box away from the wall, taking care not to damage the surrounding drywall or plaster.

- If the old box has built-in clamps securing the wires, release them to allow easy removal.

- Inspect the wires for any damage or fraying. If any wires appear damaged, it’s best to consult a licensed electrician for further evaluation and repairs.

- Ensure that the opening left behind by the old box is clear of debris or protruding wires.

Removing the old box is an important step when replacing electrical boxes. Take your time and exercise caution to avoid any accidental damage or injury during this process.

If you are not replacing an existing box and are installing a new one, you can skip this step and proceed to the next step: mounting the new box.

Step 6: Mount the New Box

Once you have removed the old box or if you are installing a new one from scratch, it’s time to mount the new electrical box. Mounting the box securely is crucial for stability and safety. Here’s how you can mount the new box:

- Position the new box over the opening in the wall or ceiling, ensuring that it aligns with nearby studs or support beams for stability.

- Use a pencil or marker to trace the outline of the box onto the wall or ceiling. This will serve as a guide for cutting the opening for the box.

- Using a utility knife or drywall saw, carefully cut along the marked outline to create an opening that matches the size and shape of the new box.

- Insert the new box into the opening and check that it fits securely. If necessary, adjust the opening to ensure a snug fit.

- Secure the box to the wall or ceiling by driving screws through the mounting holes provided on the box. Ensure that the screws penetrate the surrounding studs or support beams for a secure attachment.

- Double-check that the box is level and plumb using a level. Adjust as necessary to ensure a proper alignment.

- If the new box includes built-in clamps for securing the wires, make sure to release them for easy access during the wiring process.

Mounting the new box properly is essential for a stable and secure electrical installation. Take your time to align and secure the box correctly, as it will serve as the foundation for the rest of the wiring work.

With the new box securely mounted, we’re ready to move on to the next step: stripping and preparing the wires.

Read more: How To Ground Electrical Wires

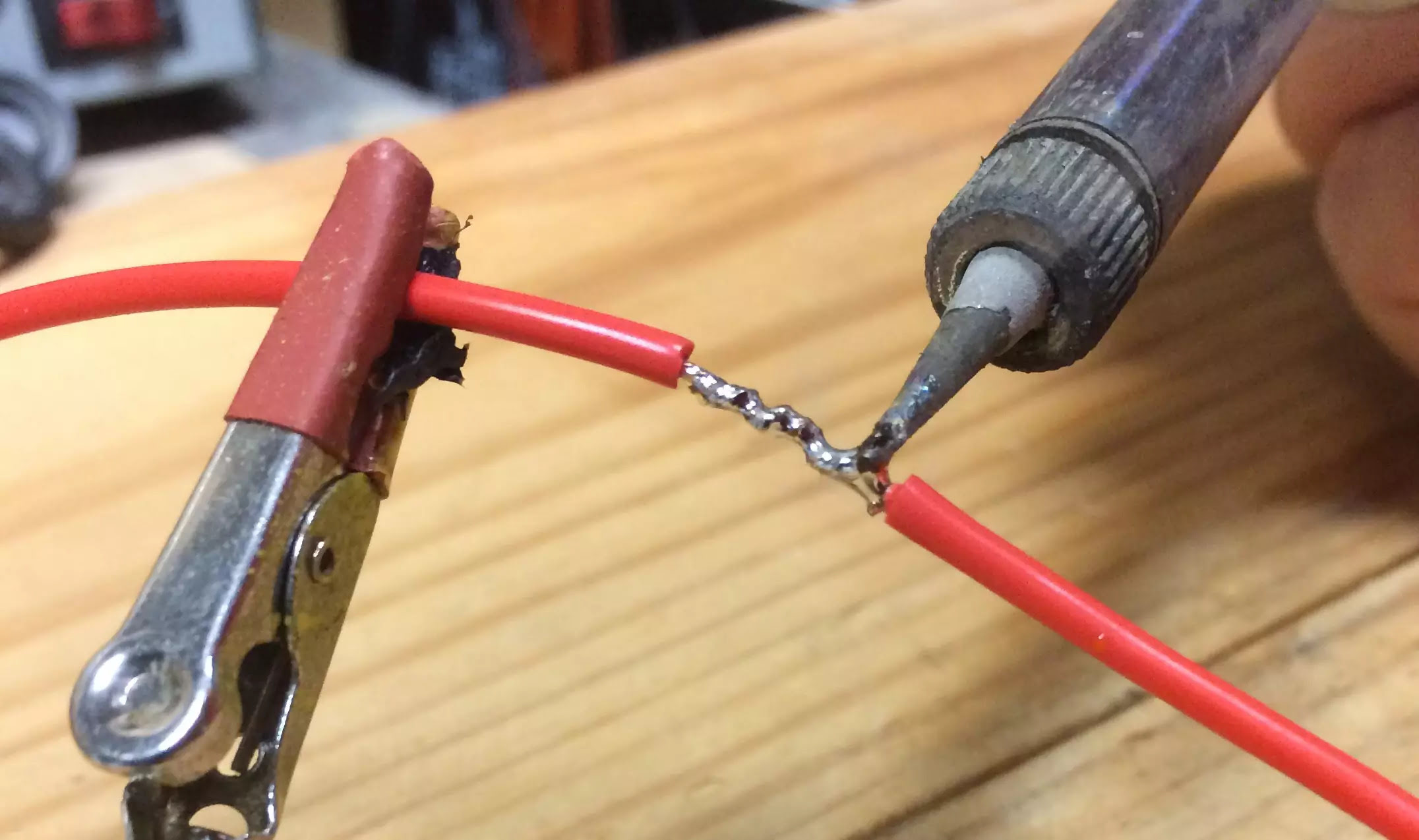

Step 7: Strip and Prepare the Wires

After mounting the new electrical box, it’s time to strip and prepare the wires for connection. Properly stripping and preparing the wires ensures a secure and reliable electrical connection. Follow these steps to strip and prepare the wires:

- Start by cutting off the outer sheathing of the electrical wire using a wire cutter or utility knife. Make a clean and even cut, being careful not to damage the individual wires inside.

- Expose approximately 1/2 inch to 3/4 inch of the individual wire conductors by gently stripping off the insulation using a wire stripper. Be careful not to nick or damage the wire conductors during this process.

- Inspect the stripped ends of the wire to ensure they are clean and free from any frayed strands or nicks. If necessary, trim any damaged portions with wire cutters and strip the wire again.

- For solid wire conductors, twist the exposed strands clockwise using needle-nose pliers. This helps to compact and secure the wire strands together for a tight connection.

- For stranded wire conductors, make sure the strands are evenly spread out and not twisted. Straighten any bent or kinked strands to ensure a proper connection.

- If the wires have different colors, match the wires based on their color-coding: typically, black or red wires are live or “hot” wires, white or gray wires are neutral wires, and green or bare copper wires are grounding wires.

- Make sure the stripped ends of the wires are long enough to reach the appropriate terminals inside the electrical box with some extra length for flexibility.

Properly stripping and preparing the wires is crucial for achieving secure and reliable electrical connections. Take your time and pay attention to detail to ensure the best possible outcome.

With the wires stripped and prepared, we can now move on to the next step: connecting the wires to the outlet or switch.

Step 8: Connect the Wires to the Outlet or Switch

Now that you have stripped and prepared the wires, it’s time to connect them to the outlet or switch inside the electrical box. Properly connecting the wires ensures a secure and functional electrical connection. Follow these steps to connect the wires:

- Identify the terminals on the outlet or switch. Typically, outlets have “hot” (gold or brass-colored), “neutral” (silver-colored), and “ground” (green or bare copper) terminals. Switches usually have “hot” (dark-colored or labeled) terminals.

- Connect the “hot” wire (usually black or red) to the “hot” terminal on the outlet or switch. Insert the bare or stripped end of the wire into the terminal and tighten the screw securely using a screwdriver. Make sure there are no loose strands of wire outside the terminal.

- Connect the “neutral” wire (usually white or gray) to the “neutral” terminal on the outlet. Follow the same process of inserting the stripped end of the wire into the terminal and tightening the screw securely. If you’re working with a switch, skip this step as switches do not require a neutral connection.

- Connect the grounding wire (usually green or bare copper) to the grounding terminal or screw on the outlet or switch. Insert the stripped end of the wire into the terminal or wrap it around the grounding screw. Tighten the screw securely to ensure a solid connection.

- For outlets, use wire connectors to secure any additional wires (if applicable), such as those branching off to other outlets or devices on the same circuit. Follow the manufacturer’s instructions for proper use of wire connectors.

- Double-check that all wire connections are secure and properly tightened. Wiggle the wires gently to ensure they are held firmly in place.

Properly connecting the wires to the outlet or switch is crucial for a secure and functional electrical system. Take your time and ensure each wire is connected to the correct terminal securely.

With the wires connected, we can now move on to the next step: securing the connections.

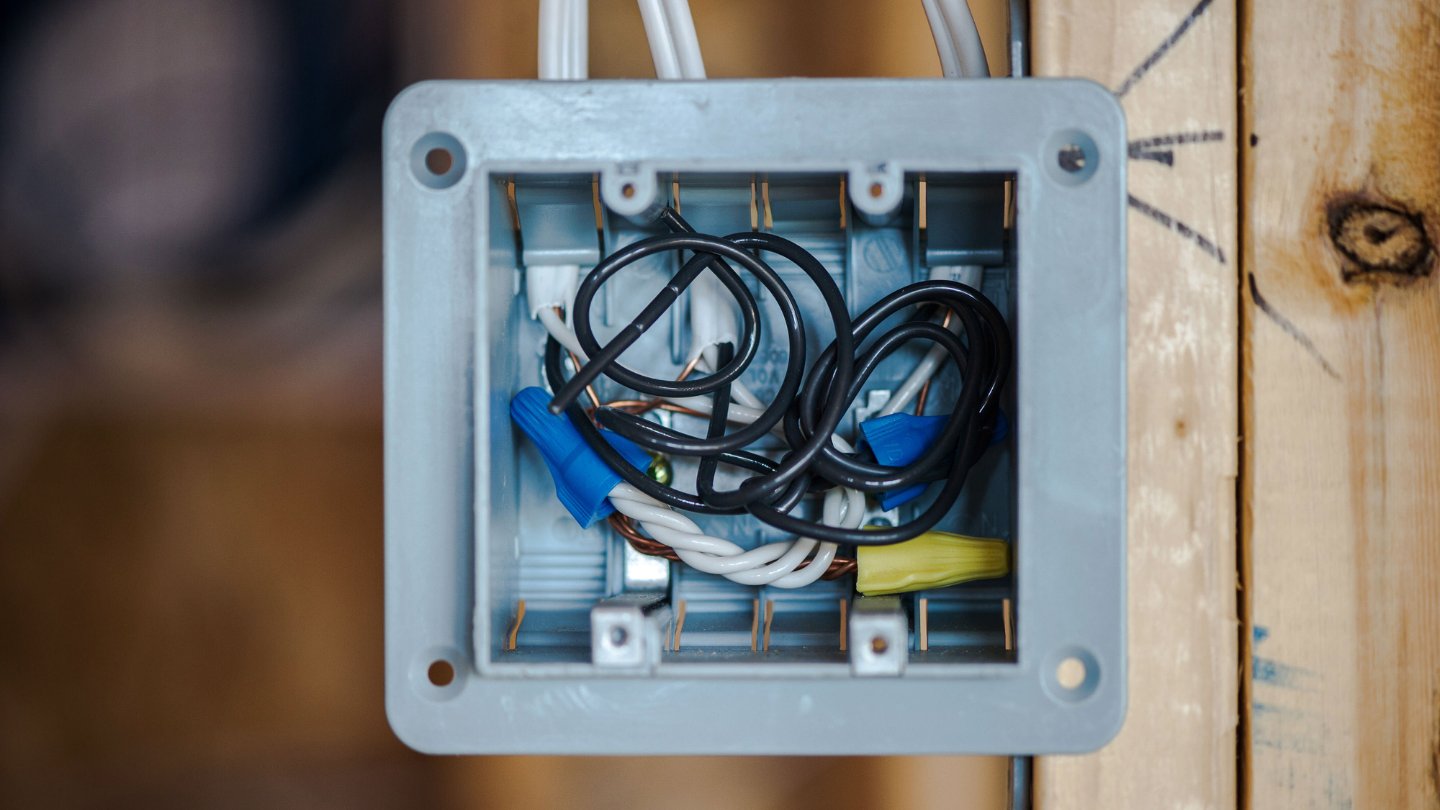

Step 9: Secure the Connections

Securing the connections is a critical step in ensuring the safety and reliability of your electrical installation. Properly securing the wire connections inside the electrical box helps prevent loose connections, electrical arcing, and potential hazards. Follow these steps to secure the connections:

- Neatly fold the connected wires into the electrical box, making sure there is enough space for the outlet or switch to fit properly.

- Use wire connectors or twist-on wire nuts to secure the wire connections. Choose connectors that are appropriately sized for the number and gauge of wires being connected. Follow the manufacturer’s instructions for proper usage of the wire connectors.

- Twist the wire connectors in a clockwise direction until they are firmly tightened. This ensures a solid connection and helps prevent the wires from coming loose over time. Do not overtighten, as it may damage the wires or connectors.

- Carefully tuck the connected wires and wire connectors into the electrical box, ensuring they are not being pinched or strained. Avoid overcrowding the box to allow for proper airflow and heat dissipation.

- Double-check that all wire connections are secure and properly insulated. Make sure there are no exposed wire conductors or loose strands. Inspect the connections for any signs of damage or overheating.

Securing the connections ensures that the wiring is properly installed and reduces the risk of electrical hazards. Take your time and pay attention to detail while securing the wire connections inside the electrical box.

With the connections secured, we can now move on to the next step: installing the cover plate.

Step 10: Install the Cover Plate

Installing the cover plate is the final step in completing the wiring of an electrical box. The cover plate not only adds a finishing touch to the installation but also provides a protective barrier and enhances the overall appearance. Follow these steps to install the cover plate:

- Select a cover plate that matches the type and style of the outlet or switch. There are various options available, including standard single-gang plates, decorative plates, and specialty plates.

- Align the cover plate over the outlet or switch, ensuring that the screw holes on the plate align with the mounting screws on the device.

- Insert the flathead or Phillips screwdriver into the screw holes on the cover plate and tighten the screws using a clockwise motion. Be careful not to overtighten the screws, as it may cause damage to the plate or device.

- Double-check that the cover plate is securely attached and does not wobble. Ensure that it sits flush against the wall or ceiling surface.

- If necessary, adjust the position of the cover plate to ensure it is level and aligned with nearby outlet or switch plates.

Installing the cover plate not only protects the electrical connections but also enhances the aesthetic appeal of the installation. Take care to select a cover plate that complements your decor and style.

Now that you have successfully installed the cover plate, we are ready for the final step: turning on the power and testing the electrical connections.

Read more: How To Splice Electrical Wire

Step 11: Turn on the Power and Test

Now that you have completed the wiring and installation of the electrical box, it’s time to turn on the power and test the electrical connections to ensure they are working properly. Follow these steps to safely turn on the power and test your installation:

- Double-check that all wire connections are securely fastened and properly insulated inside the electrical box. Ensure there are no loose wires or exposed conductors.

- Go to the main electrical panel and reset the circuit breaker or replace the fuse that corresponds to the circuit you’ve been working on.

- Switch on the circuit breaker or restore power to the circuit by turning the main switch back to the “On” position.

- Return to the outlet or switch connected to the electrical box and verify that it is receiving power. Use a voltage tester to check for the presence of electricity.

- If the voltage tester indicates that power is present, test the outlet or switch by plugging in a lamp or using a device. Ensure that it is functioning correctly by turning switches on and off or checking for power output.

- If everything is functioning as expected, your wiring installation is successful. Congratulations!

If, during the testing phase, you discover any issues such as non-functioning outlets, switches, or other electrical malfunctions, turn off the power immediately and consult a licensed electrician to diagnose and resolve the problem.

It’s important to note that if you are unsure about any aspect of the installation or if you encounter any difficulties during testing, it is wise to seek the assistance of a professional electrician.

With the power turned on and the electrical connections successfully tested, your electrical box installation is complete. You can now enjoy the benefits of a properly wired and functional electrical system.

Remember to follow all local building codes and safety guidelines throughout the entire process. Safety should always be the top priority when working with electricity.

Now that you have successfully completed the installation and testing, take a moment to appreciate your accomplishment and the peace of mind that comes with a well-executed electrical box wiring.

Disclaimer: This guide provides general instructions for wiring an electrical box and should not replace professional advice. Always consult a licensed electrician for complex or unfamiliar electrical projects.

Conclusion

Wiring an electrical box may seem like a complex task, but with proper knowledge and the right approach, you can confidently tackle this project. By following the step-by-step guide outlined in this article, you have learned the necessary techniques to wire an electrical box safely and efficiently.

Throughout the process, we emphasized the importance of safety precautions, such as turning off the power, wearing protective gear, and seeking professional help when needed. These precautions are essential for preventing electrical accidents and ensuring a successful installation.

We discussed the tools and materials needed for the job, from wire strippers and cutters to electrical boxes and wire connectors. Having the right tools at your disposal makes the wiring process smoother and more efficient.

We also covered key steps, including choosing the right box, selecting the proper wire, planning the wiring layout, removing the old box (if applicable), mounting the new box, stripping and preparing the wires, connecting them to the outlet or switch, securing the connections, and installing the cover plate.

Once you’ve completed these steps, the final and crucial step is turning on the power and testing the electrical connections. By following the outlined procedures and testing for functionality, you can ensure that your wiring installation is successful.

Always remember to adhere to local building codes and regulations and prioritize safety throughout the entire process. If you are unsure about any step or encounter difficulties, it is best to consult a licensed electrician for assistance.

With the completion of your electrical box wiring, you have achieved a significant milestone in creating a safe and functional electrical system. Take pride in your accomplishment and enjoy the benefits of a properly installed and reliable electrical infrastructure.

Disclaimer: This guide provides general instructions for wiring an electrical box and should not replace professional advice. Always consult a licensed electrician for complex or unfamiliar electrical projects.

Frequently Asked Questions about How To Wire Electrical Box

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Wire Electrical Box”