Home>Articles>How To Evaluate The Condition Of An Electrical Cord

Articles

How To Evaluate The Condition Of An Electrical Cord

Modified: August 16, 2024

Looking for articles on evaluating the condition of an electrical cord? Find valuable information and tips in this comprehensive guide.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

An electrical cord is an essential component of many electrical devices that we use in our daily lives. It serves as a conduit for electricity to flow from the power source to the device, ensuring proper functioning and safety. However, over time, electrical cords can wear out, become damaged, or deteriorate, posing a potential risk of electrical hazards.

When evaluating the condition of an electrical cord, it is crucial to consider several factors to determine whether it is safe to use or requires immediate attention. This article will guide you through the key aspects to assess when evaluating the condition of an electrical cord.

By thoroughly examining the cord and its components, you can identify any potential issues and take the necessary steps to prevent accidents, electrical shocks, or even fire hazards. Let’s dive into the specific elements that you should consider when evaluating an electrical cord.

Key Takeaways:

- Regularly evaluating the condition of electrical cords is crucial for maintaining safety and functionality. Factors such as appearance, physical damage, insulation, and compliance with safety standards should be carefully considered to prevent hazards and ensure reliability.

- Following manufacturer’s recommendations, conducting electrical testing, and choosing the right length and quality of electrical cords are essential for minimizing risks and ensuring optimal performance. Compliance with safety standards and regulations is key to maintaining a safe electrical environment.

Read more: How To Tie An Electrical Cord

Overall Appearance

The overall appearance of an electrical cord can often provide initial clues about its condition. Inspect the cord for any signs of wear, fraying, discoloration, or damage. A cord that appears old, worn out, or in poor condition may indicate underlying issues that require further investigation.

Check for any visible cracks, kinks, or bulges on the cord’s outer sheath. These irregularities can weaken the cord’s structure and compromise its insulation. Additionally, examine the cord for any signs of heat damage, such as melted areas or melted insulation, as these indicate potential overheating or electrical overloads.

It is advisable to look for any signs of moisture or water damage on the cord. Moisture can deteriorate the insulation and increase the chances of electrical leakage or shorts. If you notice any signs of moisture or dampness, it is important to address the issue promptly by drying the cord or replacing it if necessary.

Furthermore, check for any visible labeling or markings on the cord. Look for the manufacturer’s name or logo, gauge rating, voltage rating, and any safety certifications. These markings provide important information about the cord’s intended use and compliance with safety standards.

The overall appearance of an electrical cord can often give a good first impression of its condition. However, it is important to conduct a more thorough evaluation to ensure its safety and functionality. Let’s explore the next aspect to consider when evaluating an electrical cord: physical damage.

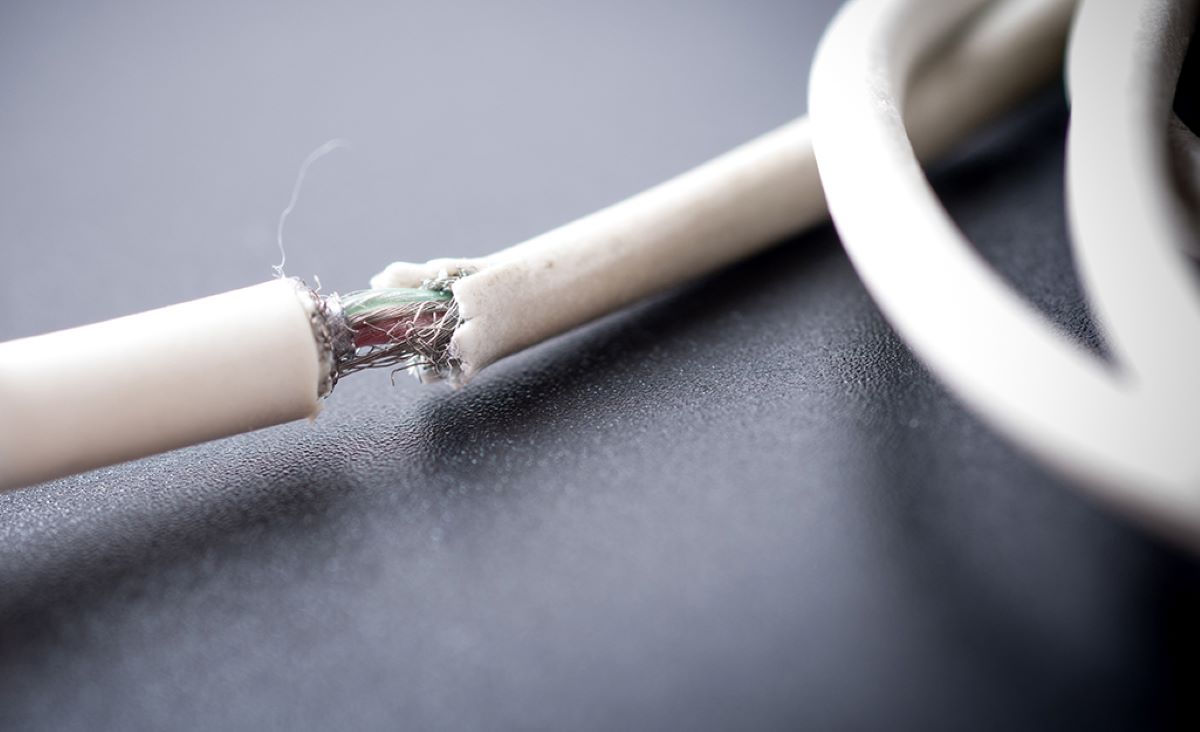

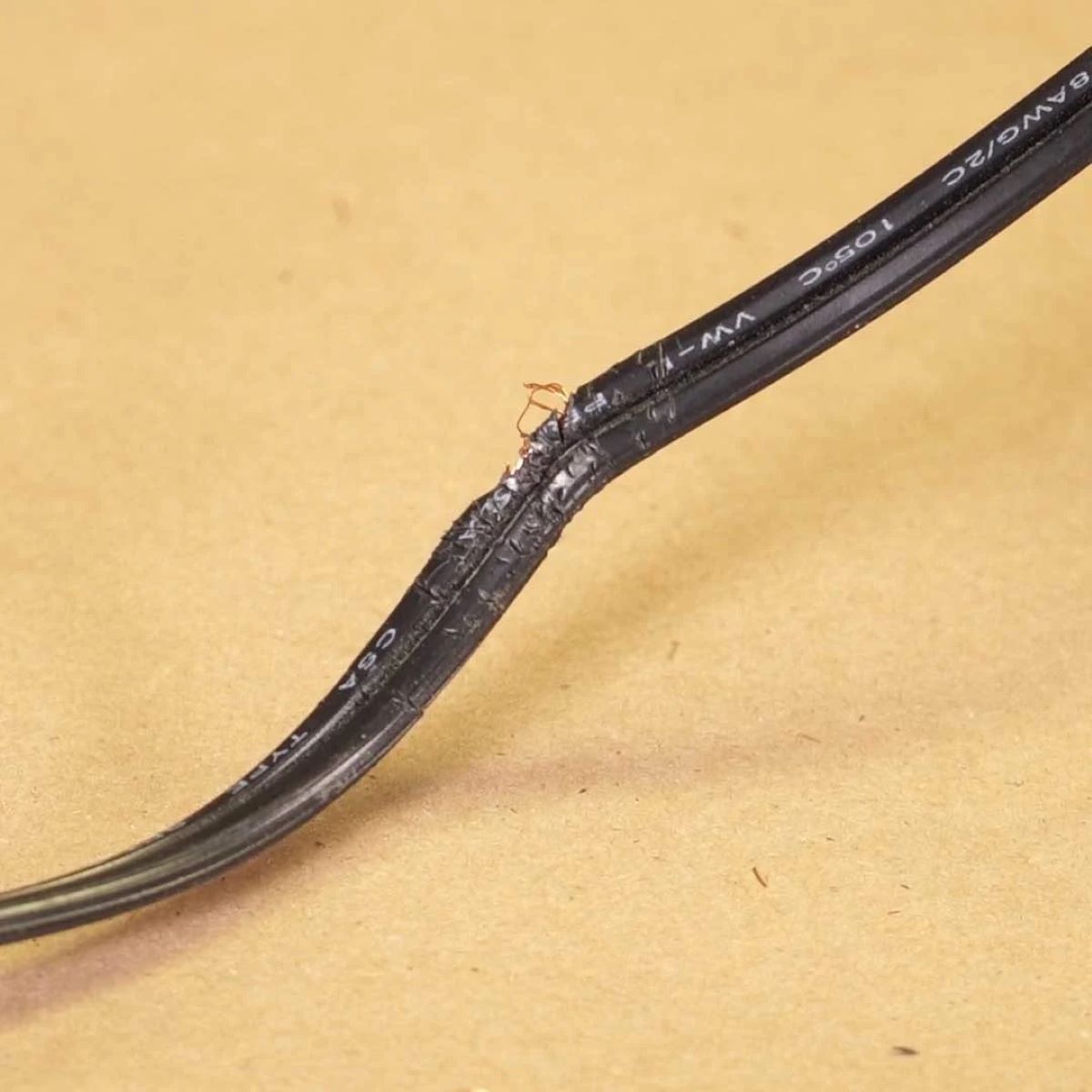

Physical Damage

Physical damage to an electrical cord can have serious implications for its safety and performance. It is essential to carefully inspect the cord for any signs of physical damage or deterioration.

First, examine the cord for any cuts, punctures, or tears in the outer sheath. These types of damage can expose the internal wires, increasing the risk of electrical shocks or short circuits. If you notice any exposed wires, it is crucial to stop using the cord immediately and seek professional assistance or replace it.

Next, check for any bends, twists, or stretches in the cord. Excessive bending or stretching can weaken the cord’s internal wires and insulation, making it more susceptible to breakage or electrical leakage. If you notice any significant deformations or excessive flexibility in the cord, it may be an indication of compromised structural integrity and require replacement.

Inspect the cord’s connectors, such as the plug and socket ends. Look for any signs of damage, such as bent or broken pins, loose connections, or missing parts. Damaged connectors can not only affect the cord’s functionality but also pose risks of electrical shocks or fires. If the connectors are damaged, it is advisable to replace the entire cord or consult a qualified electrician for repairs.

In addition, check for any signs of excessive heat on the cord. Heat damage can occur due to overloading, poor ventilation, or faulty connections. Look for discoloration, melting, or burn marks, especially near the plug or connector ends. If you detect any heat damage, it is critical to address the underlying issue and replace the cord to prevent further damage or hazards.

Regularly assessing an electrical cord for physical damage is crucial to ensure its safe usage. If you notice any significant physical damage, it is always recommended to err on the side of caution and replace the cord promptly to mitigate potential safety risks.

Next, let’s move on to examining the insulation condition of an electrical cord.

Insulation Condition

The insulation of an electrical cord plays a vital role in protecting the internal wires and preventing electrical hazards. Evaluating the insulation condition is crucial for ensuring the safety and reliability of the cord.

Start by examining the insulation for any signs of cracks, breaks, or deterioration. Insulation that is in poor condition can lead to exposed wires and increase the risk of electrical shocks or short circuits. Even minor cracks or damage to the insulation should be taken seriously and addressed promptly.

Check the flexibility of the insulation. It should be pliable and resistant to cracking or breaking when gently bent. Stiff or brittle insulation can be an indication of age or damage, and it may compromise the cord’s safety and flexibility.

Verify that the insulation is intact and extends fully to the connectors (plug and socket ends) of the cord. The insulation should securely cover the entire length of the wire, including any exposed metal parts. Partially exposed wires or inadequate insulation coverage can lead to electrical leakage or accidental contact with conductive surfaces.

Examine the insulation for any signs of melting, burning, or discoloration. These indications of heat damage suggest that the cord has been subjected to excessive heat and may not be safe for use. Heat-damaged insulation should be immediately replaced to prevent further risks.

It is important to note that different types of cords may have different insulation materials. For instance, some cords may have a rubber or PVC (polyvinyl chloride) insulation. Ensure that the insulation material is in good condition and appropriate for the intended use and environment.

Regularly inspecting the insulation condition of an electrical cord is essential for maintaining safety. If you notice any issues with the insulation, it is recommended to replace the cord or seek professional assistance to ensure proper insulation and protect against electrical hazards.

Next, we will explore the importance of assessing the quality of the plug and connectors of an electrical cord.

Plug and Connector Quality

The quality and condition of the plug and connectors of an electrical cord are crucial aspects to consider when evaluating its overall safety and performance.

Start by inspecting the plug for any signs of damage or wear. Look for cracks, breaks, or loose parts. A damaged plug can lead to poor electrical connections and increase the risk of electrical shocks or fires. It is important to replace a damaged plug or consult a qualified electrician for repairs.

Check the prongs of the plug to ensure they are straight, aligned, and clean. Bent or misaligned prongs may not make proper contact in the socket, causing electrical arcing or intermittency. If the prongs are dirty, use a soft cloth or brush to clean them. Dirty or corroded prongs can hinder good electrical conductivity and should be restored to maintain a reliable connection.

Inspect the connectors on the cord for any signs of damage, such as bent pins, loose connections, or missing parts. The connectors should fit snugly and securely into the corresponding sockets. Loose or wobbly connectors can lead to intermittent power supply or accidental disconnections, posing risks to both safety and device functionality.

Verify that the plug and connectors are in good condition and compatible with the device and electrical system. The plug should match the type of socket (e.g., two-prong or three-prong) and be designed for the appropriate voltage and current rating. Using incompatible or inadequate plugs can result in electrical mismatches, which can be hazardous to both the cord and the connected devices.

Consider the durability and construction of the plug and connectors. High-quality plugs and connectors are made of sturdy materials that can withstand regular use and provide reliable electrical connections. Cheap or flimsy plugs may wear out quickly, increasing the risk of poor connections or damage to the cord.

Ensuring the quality and integrity of the plug and connectors is essential for the safe and efficient use of an electrical cord. If you notice any issues with the plug or connectors, it is recommended to replace the cord or seek professional assistance to ensure proper functionality and mitigate potential safety risks.

Next, let’s move on to examining the flexibility and tangle-resistance of an electrical cord.

Read more: How To Cut An Electrical Cord

Flexibility and Tangle-Resistance

The flexibility and tangle-resistance of an electrical cord are important factors to consider when evaluating its usability and safety. A cord that is too rigid or prone to tangling can impact both its functionality and pose potential hazards.

Start by assessing the flexibility of the cord. It should be pliable and easily bendable without any excessive resistance or stiffness. A cord that is overly rigid or stiff may indicate aged or brittle insulation, which can increase the risk of cracks or damage to the internal wires. On the other hand, a cord that is too floppy or excessively flexible may lack proper structural support and may not provide a secure electrical connection.

Consider the length of the cord in relation to its intended use. Ensure that the length is adequate to reach the power source without unnecessary strain or tension. Using an overly short cord with excessive tension can damage the cord’s insulation or strain the connectors, compromising its safety and functionality. Additionally, using an excessively long cord can increase the chances of tangling, trip hazards, or accidental disconnections.

Assess the tangle-resistance of the cord. A cord that easily tangles can create inconvenience and risks. Tangled cords are more prone to damage, such as kinks, cuts, or twists, which can lead to exposed wires or weakened insulation. With regular use, tangled cords can also lead to stress on the connectors or unintentional disconnections. Opt for cords that are designed to resist tangling, as they are typically more durable and safe to use.

Consider the cord’s outer sheath material for its impact on flexibility and tangle-resistance. Certain materials, such as silicone or braided nylon, are known for their flexibility, pliability, and tangle-resistant properties. These materials provide better durability and resistance to kinking or tangling compared to standard plastic or rubber sheaths.

When evaluating the flexibility and tangle-resistance of an electrical cord, choose one that strikes a balance between flexibility and structural support. It should be pliable enough for easy handling and positioning, yet sturdy enough to maintain a reliable and safe connection. By selecting a cord with the appropriate flexibility and tangle-resistance, you can ensure efficient use while minimizing the risk of damage or accidents.

Next, let’s explore the importance of conducting electrical testing on an electrical cord.

When evaluating the condition of an electrical cord, consider the insulation for any cracks or damage, the plug for any signs of wear or damage, and the overall flexibility of the cord. If any issues are found, the cord should be replaced to prevent electrical hazards.

Electrical Testing

Electrical testing is an essential step in evaluating the condition and safety of an electrical cord. It involves assessing the electrical performance of the cord to ensure that it functions correctly and meets the necessary safety standards.

One of the primary tests to conduct is a continuity test. This test checks for the continuity of the internal wires, ensuring that there are no breaks or interruptions in the circuit. Using a multimeter or a continuity tester, check the continuity between the plug and the connector ends of the cord. If there is no continuity or if it fluctuates, it indicates a potential issue with the internal wiring and may require further inspection or replacement of the cord.

Another crucial test is a voltage drop test. This test measures the voltage loss across the cord when current is flowing through it. A significant amount of voltage drop can indicate excessive resistance or a poor connection within the cord. High voltage drop can lead to energy wastage, overheating, and reduced device performance. It is important to ensure that the voltage drop is within an acceptable range as specified by electrical safety standards.

Additionally, verify the proper grounding of the cord. Some cords, especially those used with equipment requiring grounding for safety purposes, have a dedicated grounding wire. Ensure that the grounding wire is intact, properly connected, and testing for continuity when the device is turned on. Proper grounding is crucial for electrical safety, protecting against electrical faults and reducing the risk of electric shock.

It is recommended to consult a qualified electrician or use specialized electrical testing equipment to perform these tests. They have the knowledge and experience to accurately interpret the test results and identify any potential issues that may require further attention.

Regularly conducting electrical testing on an electrical cord ensures its functional integrity and adherence to safety standards. If the cord fails any of the tests or exhibits abnormal electrical behavior, it is advisable to replace it or seek professional assistance to address the underlying issues.

Next, let’s discuss the importance of considering the length and adequacy of an electrical cord.

Length and Adequacy

The length and adequacy of an electrical cord are important factors to consider when evaluating its suitability for a specific application. It is essential to choose a cord with the appropriate length to ensure convenience, safety, and optimal performance.

Start by assessing the length of the cord in relation to its intended use. The cord should be long enough to reach the power source without requiring excessive stretching or straining. Using a cord that is too short can lead to tension on the connectors or strain the cord itself, potentially causing damage to the insulation or connectors. Conversely, using a cord that is excessively long can create tripping hazards or increase the risk of tangling.

Consider the environment in which the cord will be used. If the cord needs to be routed through obstacles or around corners, ensure that it has enough length to maneuver without creating sharp bends or kinks. Bends and kinks can weaken the cord’s structure, leading to damaged insulation or exposed wires.

Take into account the power requirements of the connected device. The cord should be capable of handling the electrical load without voltage drop or overheating. If the device requires high power consumption, it may be necessary to use a heavier gauge wire to minimize voltage drop and ensure safe operation.

It is also important to consider the amperage rating of the cord. Ensure that the cord is rated to handle the current required by the device. Using a cord with insufficient amperage capacity can lead to overheating, electrical overload, or even damage to the equipment. Checking the manufacturer’s specifications or consulting a qualified electrician can help determine the appropriate amperage rating for the cord.

Additionally, consider any special requirements or safety considerations for the specific application. For example, outdoor cords should be weather-resistant and have appropriate insulation to withstand exposure to moisture, UV rays, or extreme temperatures. Specialized equipment or industrial applications may require cords with specific certifications or approvals to ensure compliance with safety standards.

By carefully assessing the length and adequacy of an electrical cord, you can ensure optimal performance, safety, and convenience. Choosing a cord that is suitable for the specific application and environment helps to minimize the risk of accidents, improve efficiency, and protect both the cord and connected devices.

Next, let’s explore the importance of considering the manufacturer’s recommendations for an electrical cord.

Manufacturer’s Recommendations

When evaluating an electrical cord, it is essential to consider the manufacturer’s recommendations and guidelines. The manufacturer’s recommendations provide valuable insights into the intended use, limitations, and safety precautions associated with the cord.

Start by reviewing the user manual or product documentation provided by the manufacturer. This documentation often includes specific instructions on how to safely and effectively use the cord. It may contain information on the recommended applications, operating temperatures, voltage and current ratings, and any special considerations.

Pay attention to any warnings or limitations specified by the manufacturer. They often highlight potential risks or restrictions that should be taken into account to ensure safe usage of the cord. For example, the manufacturer may specify the maximum load capacity, environmental conditions, or usage restrictions that should be followed to prevent electrical hazards or damage to the cord.

Consider the manufacturer’s recommendations regarding maintenance and periodic inspections. They may provide guidance on how often the cord should be inspected, what signs of wear or damage to look for, and when to replace the cord for optimal safety and performance. Adhering to these recommendations helps to prolong the lifespan of the cord and reduce the risk of accidents.

Manufacturers often provide guidelines on storage and proper handling of the cord. They may recommend coiling the cord in a specific manner or suggest the use of cord reels to prevent tangling and damage. Following these guidelines can help protect the cord from unnecessary wear and tear, ensuring its longevity and functionality.

Additionally, consider any recommendations for specific accessories or components that should be used with the cord. This may include extension cord reels, cord covers, or additional safety devices to enhance the functionality and safety of the cord in certain applications or environments.

By following the manufacturer’s recommendations, you can ensure that the electrical cord is used in accordance with its intended purpose and specifications. This helps to maintain its safety, reliability, and longevity while minimizing the risks of accidents or equipment damage.

Next, let’s explore the importance of compliance with electrical safety standards when evaluating an electrical cord.

Read more: How To Store An Electrical Cord

Compliance with Electrical Safety Standards

Compliance with electrical safety standards is of utmost importance when evaluating the condition of an electrical cord. These standards are in place to ensure the safe and reliable operation of electrical equipment and to minimize the risk of electrical accidents or hazards.

One important safety standard is the electrical code or regulation established by the relevant authorities in your location. This code sets guidelines for the design, installation, and maintenance of electrical systems, including the use of electrical cords. It specifies requirements such as conductor size, insulation ratings, grounding, and overcurrent protection. It is vital to ensure that the electrical cord meets the requirements specified in the electrical code for the specific application.

Look for safety certifications or marks on the cord that indicate compliance with recognized safety standards. These certifications, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association), ensure that the cord has undergone rigorous testing and meets specific safety criteria. The presence of these certifications provides assurance that the cord has been manufactured to high safety standards and has the necessary safety features.

Consider the intended use or industry-specific regulations that may apply to the cord. Certain applications, such as medical devices, industrial machinery, or hazardous environments, may have additional safety requirements. It is important to ensure that the cord meets these specific regulatory standards to ensure proper safety and performance in such environments.

Regularly reviewing and updating your knowledge of electrical safety standards and regulations is paramount to staying informed and ensuring compliance. This can involve referring to the latest editions of electrical codes, following industry publications, or consulting with qualified professionals in the field.

By using electrical cords that comply with the relevant safety standards, you can have confidence in their reliability, safety, and performance. Compliance with safety standards ensures that the cords are built to withstand electrical loads, minimize the risk of electrical faults or accidents, and provide peace of mind for users.

Next, let’s conclude our evaluation of the condition of an electrical cord.

Conclusion

When evaluating the condition of an electrical cord, several factors must be considered to ensure its safety, functionality, and compliance with electrical standards. By examining the overall appearance, physical damage, insulation condition, plug and connector quality, flexibility and tangle-resistance, performing electrical testing, considering the length and adequacy, reviewing manufacturer’s recommendations, and ensuring compliance with electrical safety standards, you can make an informed assessment of the cord’s condition.

The overall appearance and physical condition of the cord provide initial indicators of its safety and longevity. Any signs of wear, fraying, or damage should be addressed promptly to prevent electrical hazards or device malfunction. Similarly, assessing the insulation condition ensures the protection of internal wires and reduces the risk of electrical leakage or short circuits.

The quality and integrity of the plug and connectors are vital for safe and reliable connectivity. Damaged or loose connectors can compromise the cord’s functionality and pose risks of electrical shocks or fires. A flexible and tangle-resistant cord enhances convenience and reduces the chances of damage or accidents during use.

Conducting electrical testing, such as continuity and voltage drop tests, helps to identify any internal wiring issues or excessive resistance that may affect the cord’s performance. Additionally, ensuring the cord’s length and adequacy for the intended use minimizes strain on the cord and connectors, promoting safety and efficient operation.

It is essential to follow the manufacturer’s recommendations regarding the cord’s usage, maintenance, and storage. Adhering to these guidelines can prolong the cord’s lifespan and mitigate potential risks. Lastly, compliance with electrical safety standards and regulations ensures that the cord meets the required safety criteria, providing confidence in its reliability and safety.

Regular evaluation of the condition of an electrical cord is vital for maintaining a safe electrical environment. If any concerns or issues arise during the evaluation, it is recommended to consult a qualified electrician or replace the cord if necessary. Prioritizing safety and proper maintenance will contribute to the longevity and performance of the cord, ensuring a reliable and hazard-free electrical experience.

Frequently Asked Questions about How To Evaluate The Condition Of An Electrical Cord

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Evaluate The Condition Of An Electrical Cord”