Articles

How To Use A LP30 Laser Level To Level Floor

Modified: February 22, 2024

Discover the best techniques and tips for using an LP30 laser level to level your floor in this comprehensive article. Improve your DIY skills with expert advice.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Leveling a floor is an essential step in any construction or renovation project. A level floor not only ensures the structural integrity of a building but also provides a stable and even surface for various activities. While there are several methods to level a floor, one of the most accurate and efficient tools available is the LP30 Laser Level.

Key Takeaways:

- The LP30 Laser Level is a state-of-the-art tool for precise floor leveling, providing automatic self-leveling and accurate measurements. Proper preparation, including checking the surface and gathering necessary tools, is essential for successful floor leveling.

- After leveling the floor with the LP30 Laser Level, it’s crucial to clean up the area, remove the device properly, and store it in a safe, dry location. Following these steps ensures the device remains in optimal condition for future use.

Read more: How To Use A Laser Level To Check A Floor

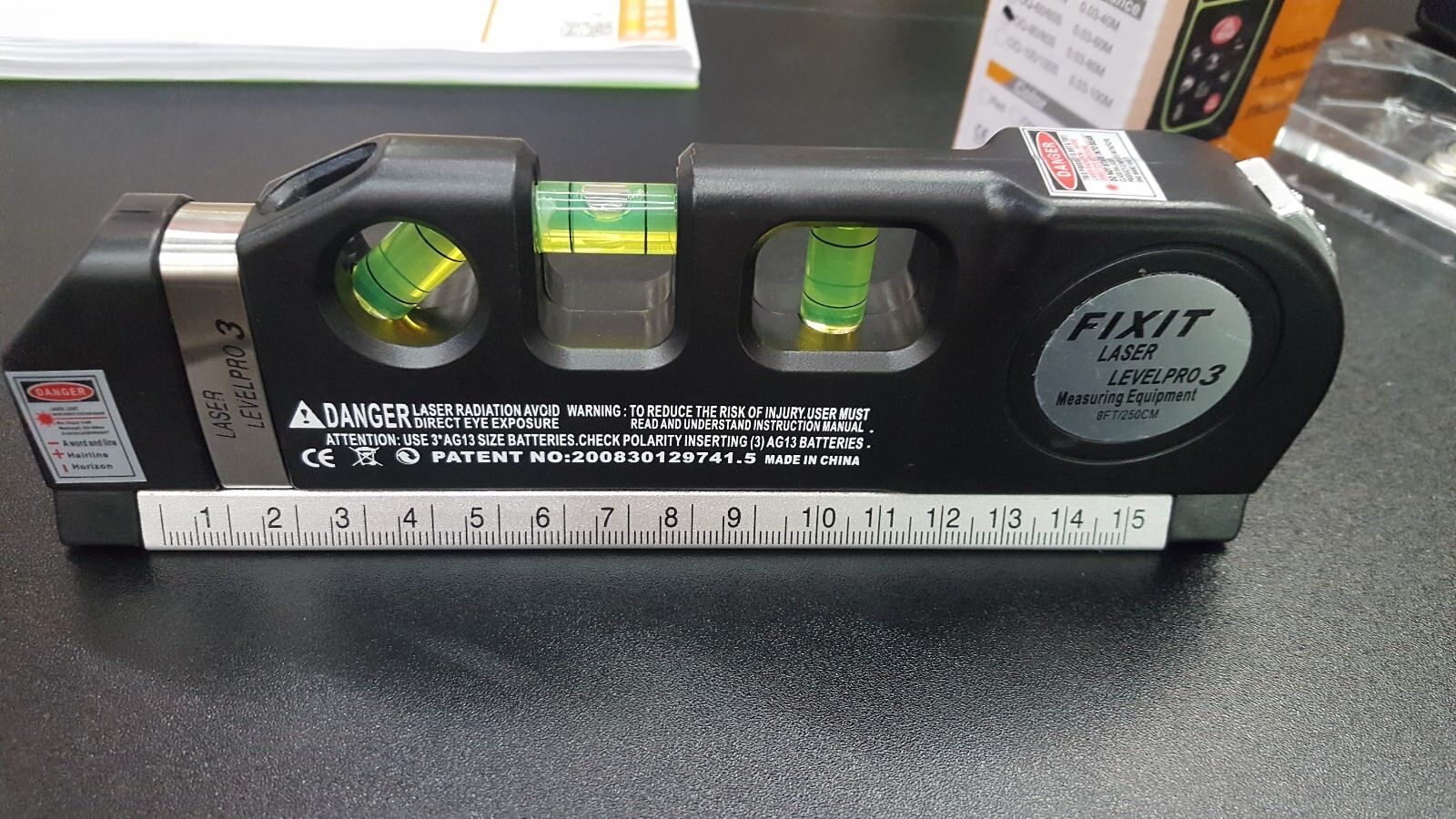

Understanding the LP30 Laser Level

The LP30 Laser Level is a state-of-the-art device designed for precise floor leveling. It utilizes powerful laser technology to project a perfectly straight line across a surface, allowing you to accurately determine the height variations in a floor. With its automatic self-leveling feature, the LP30 Laser Level eliminates the need for manual adjustments, making the floor leveling process quicker and more efficient.

Preparing for Floor Leveling

Before using the LP30 Laser Level to level a floor, it is crucial to properly prepare the area. This involves checking the surface, gathering the necessary tools, and clearing the workspace.

Checking the Surface

Begin by inspecting the floor surface to identify any major irregularities or high spots. This will help you determine the areas that require the most attention during the leveling process. Use a straight edge or a long level to detect any significant deviations from a level plane.

Gathering the Necessary Tools

Next, gather the tools and materials you will need for the floor leveling process. This may include the LP30 Laser Level, a tripod or mounting bracket, a bubble level for additional accuracy, a pencil for marking reference lines, and any leveling compounds or patching materials required to fill in gaps or uneven areas.

Read more: How To Use ToughBuilt 30 Ft. Laser Level

Clearing the Area

Clear the area of any obstacles that may interfere with the laser projection or hinder your movement during the leveling process. Remove furniture, rugs, and other items from the room, and ensure that the floor surface is free of debris or obstructions.

Checking the Surface

Before using the LP30 Laser Level to level a floor, it is important to thoroughly examine the surface for any irregularities or high spots. This step allows you to identify areas that require additional attention during the leveling process and ensures a smoother and more accurate outcome.

To begin, grab a straight edge or a long level and place it across different sections of the floor. Pay close attention to any visible gaps or deviations from a level line. Observe if there are any areas where the floor slopes or dips significantly.

If you notice any major deviations, mark them down on a notepad or take photos for reference. These markings will help you prioritize problem areas and determine the best course of action during the leveling process.

It is important to keep in mind that slight variations in the floor surface are normal and can be easily corrected. However, if you come across significant deviations, such as large gaps or uneven sections, you may need to consider using leveling compounds or self-leveling materials to rectify the issue.

Additionally, pay attention to the structural integrity of the floor. Look for any signs of damage, such as cracks or rot, which may need to be repaired before proceeding with leveling. It is crucial to address these issues to ensure a stable and durable floor.

Take note that the LP30 Laser Level is highly accurate and can detect even minor variations in the surface. By carefully examining the floor before starting the leveling process, you can save time and effort by focusing on specific problem areas more effectively.

Overall, checking the surface thoroughly is an essential step in preparing for floor leveling. It allows you to identify any irregularities, prioritize problem areas, and determine the scope of the leveling project. By addressing these issues early on, you can ensure a successful and precise floor leveling process using the LP30 Laser Level.

Gathering the Necessary Tools

Before using the LP30 Laser Level to level a floor, it is important to gather all the necessary tools and materials. Having the right equipment on hand will ensure a smooth and efficient floor leveling process.

Here are some essential tools and materials you will need:

- LP30 Laser Level: The star of the show, the LP30 Laser Level is a precision tool that projects a straight and level line on the floor surface. It is equipped with automatic self-leveling capabilities, making the leveling process much easier and accurate.

- Mounting Bracket or Tripod: To properly position and stabilize the LP30 Laser Level, you will need a mounting bracket or a tripod. These accessories provide a secure base for the laser level, allowing you to adjust the height and angle as needed.

- Bubble Level: Although the LP30 Laser Level is designed for precise leveling, using a bubble level can provide an extra level of accuracy. This handheld tool helps you ensure that the floor is perfectly level in all directions.

- Pencil or Marker: You’ll need a pencil or marker to make reference marks on the floor during the leveling process. These marks will help you keep track of the laser line and indicate areas that require further attention or adjustment.

- Leveling Compounds or Patching Materials: Depending on the condition of the floor, you may need to use leveling compounds or patching materials to fill in gaps, cracks, or uneven areas. These materials help create a smooth and level surface before applying flooring materials.

Make sure to check that all your tools are clean and in good working condition before starting the leveling process. Replace any worn out or damaged accessories to ensure accurate results.

It is also a good idea to have a notepad or a digital device on hand to document any measurements, observations, or adjustments during the floor leveling process. This information will serve as a helpful reference for future floor maintenance or renovations.

Gathering the necessary tools and materials beforehand saves you time and minimizes interruptions during the leveling process. Being well-prepared ensures that you have everything you need to achieve a perfectly level floor using the LP30 Laser Level.

Clearing the Area

Before using the LP30 Laser Level to level a floor, it is crucial to clear the area of any obstacles or debris. This step ensures an unobstructed workspace and allows the laser level to function optimally.

Here are a few key steps to follow when clearing the area:

- Remove Furniture and Objects: Start by removing any furniture, rugs, or other objects from the room. These items can obstruct the laser projection or hinder your movement during the leveling process. Clearing the area provides you with ample space to work efficiently.

- Sweep or Vacuum the Floor: Thoroughly sweep or vacuum the floor to remove any loose dirt, debris, or dust. A clean surface minimizes the risk of interference with the laser level and ensures accurate leveling results.

- Check for Obstacles: Look out for any potential obstacles that may interfere with the laser projection. This includes elements such as protruding nails, uneven surfaces, or power cords. Keep a keen eye on the entire area to ensure a clear path for the laser line.

- Secure Loose Flooring: If there are any loose floorboards or tiles, it’s important to secure them before starting the leveling process. Loose flooring can affect the accuracy of the laser level and compromise the final results. Make sure to fix or reattach any unstable flooring elements.

Once you have cleared the area and ensured a clean and obstacle-free workspace, you can proceed to set up and calibrate the LP30 Laser Level.

Read more: How To Repair A LM30 Laser Level

Setting Up the LP30 Laser Level

Properly setting up the LP30 Laser Level is crucial for accurate floor leveling. Follow these steps to ensure a successful setup:

- Power On the Device: Turn on the LP30 Laser Level by pressing the power button. Wait for the device to initialize and stabilize. Ensure that the batteries are fully charged, or connect the laser level to a power source if it has that capability.

- Mount the Laser Level: Attach the LP30 Laser Level to a mounting bracket or tripod. Make sure that the mounting surface is stable and level. Adjust the height of the laser level to the desired position, ensuring that it is approximately at the height of the reference point.

- Calibrate the Laser: The LP30 Laser Level typically has a self-leveling feature, but it is still essential to calibrate it to ensure accurate results. Consult the device’s user manual for specific calibration instructions. This step guarantees that the laser level is accurately projecting a level line across the floor surface.

With the LP30 Laser Level set up and calibrated, you are ready to begin the floor leveling process. The laser line projected by the device will serve as your reference point for achieving a perfectly level floor.

Remember to double-check that the area is clear of any potential obstacles or interference. This will ensure a smooth and uninterrupted leveling process using the LP30 Laser Level.

Powering On the Device

Before using the LP30 Laser Level to level a floor, it is important to ensure that the device is properly powered on. This step allows the laser level to initialize and stabilize, ensuring accurate and reliable performance throughout the leveling process.

Here is a step-by-step guide on how to power on the LP30 Laser Level:

- Check Battery Life: If your LP30 Laser Level is powered by batteries, start by checking the battery life. Ensure that the batteries are fully charged or replace them if necessary. This ensures that the laser level will have sufficient power to operate effectively without any interruptions.

- Locate the Power Button: The LP30 Laser Level has a power button typically located on the side or top of the device. It is usually marked with a power symbol (a circle with a line through it). Take a moment to locate and familiarize yourself with the power button.

- Press the Power Button: Once you have located the power button, press it to turn on the LP30 Laser Level. Hold the button for a few seconds until the device powers on. You may see a power indicator light or hear a beep indicating that the laser level is now active.

- Wait for Initialization: After powering on the LP30 Laser Level, it needs some time to initialize and stabilize. This process typically takes a few seconds to a minute, depending on the specific device. Allow the laser level to complete its initialization before proceeding with the floor leveling process.

- Ensure Power Source: If your LP30 Laser Level has a power cord option, make sure it is connected to a suitable power source. Check that the power cable is securely plugged into an electrical outlet or an appropriate power supply. This ensures a steady and uninterrupted power supply throughout the leveling process.

Once the LP30 Laser Level is powered on and fully initialized, it is ready to be used for leveling the floor. Keep in mind that if the device has an automatic self-leveling feature, it will continuously adjust to maintain a level laser line as you move and position it across the floor surface.

Remember to follow all safety precautions outlined in the device’s user manual and wear appropriate protection, such as safety glasses, when working with the laser level. These precautions help ensure a safe and successful floor leveling process.

By properly powering on the LP30 Laser Level, you can take full advantage of its precise leveling capabilities, allowing you to achieve accurate and professional floor leveling results with ease.

Mounting the Laser Level

Once you have powered on the LP30 Laser Level, the next step in the floor leveling process is to mount the device correctly. Proper mounting ensures stability and allows the laser level to project a straight and level line across the floor surface. This line serves as a reference for achieving an accurately leveled floor.

Follow these steps to mount the LP30 Laser Level:

- Choose a Mounting Bracket or Tripod: Depending on the specific model of the LP30 Laser Level, you may use either a mounting bracket or a tripod for proper positioning. A mounting bracket provides stability by attaching the laser level to a wall or vertical surface, while a tripod allows for more flexibility in adjusting the height and angle.

- Attach the Laser Level to the Mounting Bracket or Tripod: Connect the LP30 Laser Level to the chosen mounting accessory. Carefully align the device with the bracket or tripod attachment mechanism and secure it in place. Ensure that the connection is tight and stable to prevent any movement or wobbling during the leveling process.

- Position the Laser Level: Adjust the height and angle of the laser level to the desired position. The height should be approximately at the level of the reference point on the floor. Use the adjustment knobs or levers on the mounting bracket or tripod to position the laser level accurately.

- Secure the Mounting Bracket or Tripod: Once you have positioned the laser level, tighten the mounting bracket or tripod to secure it in place. Ensure that it is tightly fastened to prevent any unintended movement or shifting during the leveling process.

- Verify Stability: After mounting the LP30 Laser Level, gently shake or tap the device to ensure that it is securely attached and stable. A stable mount is crucial for the laser level to function properly and project a straight and accurate line across the floor surface.

Remember that the LP30 Laser Level should be positioned in a location where the projected laser line will cover the entire area you plan to level. Make adjustments to the height and angle of the laser level as needed to achieve this coverage. It is also important to keep the laser level away from any potential obstructions or obstacles that may interfere with the laser projection.

By following these steps to mount the LP30 Laser Level correctly, you can ensure stability, accuracy, and reliability throughout the floor leveling process. The laser line projected by the device will serve as your reference point for achieving a level floor, providing you with precise results each time.

Calibrating the Laser

Before proceeding with the floor leveling process using the LP30 Laser Level, it is important to calibrate the device to ensure accurate and reliable results. Calibration ensures that the laser is projected at the correct level, allowing you to achieve precise floor leveling.

Follow these steps to calibrate the LP30 Laser Level:

- Locate the Calibration Controls: Identify the calibration controls on the laser level. This may include buttons, knobs, or switches specifically designated for calibration. Consult the user manual of your LP30 Laser Level for precise instructions on locating the calibration controls.

- Place the Laser Level on a Level Surface: Find a flat and level surface, such as a table or countertop, to place the laser level on during the calibration process. Ensure that the surface is stable and free from any movement or vibrations.

- Activate the Calibration Mode: Follow the instructions in the user manual to activate the calibration mode of the LP30 Laser Level. This may involve pressing a specific combination of buttons, turning a knob to a calibration position, or engaging a switch.

- Observe the Laser Line: Once the laser level is in calibration mode, observe the laser line projected by the device. It should be perfectly level and aligned with the reference point on the floor or leveling surface.

- Make Necessary Adjustments: Using the calibration controls, make any necessary adjustments to the laser level to ensure that the line is perfectly level. This may involve fine-tuning the position or angle of the laser, or using built-in leveling mechanisms to ensure accuracy.

- Verify the Calibration: After making adjustments, recheck the laser line to ensure that it is accurately leveled. Repeat the calibration process if needed until the line is precisely level.

It is important to note that calibration procedures may vary depending on the specific model of the LP30 Laser Level. Consult the user manual provided by the manufacturer for detailed instructions on achieving accurate calibration results.

Read more: How To Use A Laser Level

Leveling the Floor

With the LP30 Laser Level calibrated and ready for use, you can now proceed with the floor leveling process. Follow these steps to effectively level the floor:

- Start at the Reference Point: Begin at the reference point you have established on the floor. This point should be at the desired level or height for the entire floor.

- Adjust the Laser Level: Position and adjust the laser level as needed to project the laser line across the floor surface. Use the height and angle adjustments provided by the mounting bracket or tripod to align the laser level accurately.

- Mark the Reference Line: Using a pencil or marker, mark the laser line projected by the device on the floor surface. This reference line will guide you in determining areas that need to be leveled or adjusted.

- Work Across the Room: Gradually move the laser level across the room, following the marked reference line. Adjust the height and angle of the laser level as necessary to maintain a level line. As you move, mark additional reference lines to guide the leveling process.

Continue this process until you have covered the entire floor surface, marking reference lines and identifying areas that require leveling or adjustment. Use additional leveling tools, such as a bubble level, to double-check the accuracy of the floor level.

Once the floor leveling process is complete, you can proceed with making necessary adjustments based on the markings and reference lines. This may involve using leveling compounds, patching materials, or other appropriate methods to address uneven areas.

By calibrating the LP30 Laser Level and following the floor leveling steps accurately, you can achieve a level and even floor surface, ensuring stability and precision in your construction or renovation project.

Starting at the Reference Point

When using the LP30 Laser Level to level a floor, it is crucial to begin the leveling process at a reference point. The reference point serves as the starting point and baseline for achieving a consistently level floor throughout the entire space.

Here are the steps to effectively start at the reference point:

- Select a Suitable Reference Point: Choose a point on the floor that you consider the ideal level or height for the entire space. This can be a specific area or a marked spot that you want the rest of the floor to be leveled to.

- Position the LP30 Laser Level: Place the LP30 Laser Level at the reference point. This can be done by ensuring that the laser line projected by the device aligns with the selected point on the floor.

- Adjust the Laser Level Height: Use the height adjustment feature provided by the mounting bracket or tripod to position the laser level at the desired height. Make sure that the laser line is precisely aligned with the reference point.

- Verify the Levelness: Double-check the levelness of the laser line by using a bubble level. Place the bubble level on the floor next to the reference point and adjust the laser level as needed to ensure that the line is perfectly level.

Starting at the reference point allows you to establish a level baseline from which you can work across the entire floor surface. By ensuring that the laser line is perfectly level at the starting point, you can maintain consistency and accuracy in the leveling process.

Once the LP30 Laser Level is correctly positioned and aligned with the reference point, you can proceed to adjust the laser level as you move across the room. This will help you identify areas that are higher or lower than the desired level and require further attention.

Remember to mark the reference line projected by the laser level using a pencil or marker. This will serve as a visual guide as you work across the room, helping you identify areas that need to be leveled or adjusted.

Starting at the reference point ensures that your floor leveling process is precise and consistent, resulting in a level and even floor surface throughout the entire space.

Adjusting the Laser Level

When using the LP30 Laser Level to level a floor, it is important to be able to adjust the device as you move across the room. This allows you to maintain a perfectly level laser line and accurately identify areas that require leveling or adjustment. Here are the steps for adjusting the laser level:

- Position the Laser Level: Place the LP30 Laser Level at the starting reference point and ensure that the laser line aligns with the desired level.

- Observe the Laser Line: Look closely at the laser line projected by the device as it spans across the floor surface. Observe any variations or deviations in the levelness of the line.

- Identify Areas to Adjust: As you observe the laser line, identify any areas where the line deviates from being perfectly level. These areas may appear higher or lower than the reference line.

- Make Small Adjustments: With the identified areas in mind, use the adjustment mechanisms on the mounting bracket or tripod to make small adjustments to the laser level’s height or angle. These adjustments will help bring the laser line into perfect alignment with the desired level.

- Observe the Laser Line Again: After making the adjustments, observe the laser line again to see if it is now level across the floor surface. If there are still deviations, make further adjustments until the line is perfectly level.

- Continue Adjusting as You Move: As you move across the room, continue to monitor the laser line and make necessary adjustments to maintain the levelness. Regularly check the line against the reference marks you have made to ensure consistency and accuracy.

By adjusting the laser level as you progress, you can effectively level the entire floor surface. Regularly checking and correcting any deviations in the laser line guarantees an even and level result. It is important to have a keen eye for detail and precision to ensure the accuracy of the leveling process.

Remember, when making adjustments to the laser level, do so in small increments to achieve the desired levelness gradually. Patience and attention to detail are essential in achieving a perfectly leveled floor using the LP30 Laser Level.

When using a LP30 laser level to level a floor, make sure to set up the level on a stable surface and adjust the height to the desired level. Use the laser line to mark the reference points on the floor and adjust as needed for a perfectly level surface.

Marking the Reference Line

When using the LP30 Laser Level to level a floor, marking the reference line is a crucial step in the process. The reference line serves as a visual guide, indicating the desired level across the floor surface. By marking this line, you can easily identify areas that need to be leveled or adjusted. Here are the steps for marking the reference line:

- Position the Laser Level: Start by placing the LP30 Laser Level at the starting point, aligning it with the reference point you have established. Ensure that the laser line is projected precisely at the desired level.

- Observe the Laser Line: Carefully observe the laser line as it spans across the floor surface. Pay close attention to how it intersects with the floor and any variations in levelness.

- Use a Pencil or Marker: As you observe the laser line, take a pencil or marker and make small marks along the line at regular intervals. These marks will serve as your reference points for identifying areas that require leveling or adjustment.

- Continue Marking Along the Line: Move along with the laser level, marking the reference line at regular intervals as you progress across the room. Ensure that the marks are clear and easily visible.

By marking the reference line, you create a visual guide that helps you identify areas of the floor that are not level. The marked reference points serve as checkpoints as you work on leveling the floor surface.

The reference marks also act as a reference for ensuring consistency and accuracy across the entire floor. They allow you to easily compare subsequent laser lines with the reference line, ensuring that the entire floor is leveled to the desired standard.

As you continue the floor leveling process, refer back to the marked reference line regularly. Use it as a point of comparison to identify areas that need additional leveling or adjustment. Recheck the laser line against the reference marks to ensure that the leveling process remains consistent and accurate throughout.

By marking the reference line, you’ll have a visual guide that enables you to achieve precise and consistent leveling results using the LP30 Laser Level.

Read more: How To Use A Self Leveling Laser Level

Working Across the Room

Once you have marked the reference line with the LP30 Laser Level, it is time to work across the room to level the entire floor surface. This involves moving the laser level from one end of the room to the other, making necessary adjustments as you go. Here are the steps for working across the room:

- Position the Laser Level: Start at one end of the room, placing the LP30 Laser Level at the reference line you have marked. Ensure that the laser line aligns with the marked reference points.

- Observe the Laser Line: As you move the laser level across the room, carefully observe the laser line to identify any deviations from the reference line. Pay attention to areas where the line may appear higher or lower than the reference marks.

- Adjust the Laser Level: If you notice any deviations, make the necessary adjustments to the laser level to bring the line back into alignment with the reference marks. This may involve adjusting the height or angle of the device.

- Mark Additional Reference Points: As you progress across the room, continue to mark reference points along the laser line at regular intervals. These additional marks will help you track the leveling progress and identify any areas that require further attention.

- Continue the Process: Repeat the process of observing, adjusting, and marking as you move the laser level across the room until you reach the opposite end. Maintain a steady pace and make precise adjustments to ensure a consistently leveled floor.

Checking and Adjusting the Level

Once you have worked across the room and leveled the entire surface using the LP30 Laser Level, it is important to perform a final check and make any necessary adjustments to ensure an accurately leveled floor. Here’s how:

- Use a Bubble Level: Take a bubble level and place it on various areas of the floor surface. Check if the bubble is centered within the level’s indicator lines. If the bubble indicates that an area is not level, additional adjustments may be needed.

- Make Necessary Adjustments: If you identify areas that are not level during the bubble level check, use the LP30 Laser Level to make final adjustments. Reposition the laser level and adjust its height and angle to correct any deviations from the desired levelness.

- Recheck and Fine-tune: Once you have made the final adjustments, recheck the laser line and use the bubble level to verify the levelness of the floor surface. Fine-tune as necessary until you achieve a consistently level floor.

By working across the room and continuously checking and adjusting the level, you can ensure that the entire floor surface is leveled accurately with the LP30 Laser Level. Taking the time to perform a final check and fine-tune the levelness ensures a high-quality result.

Remember to follow the manufacturer’s instructions for using the LP30 Laser Level and exercise caution while working with the device. By maintaining precision and attentiveness throughout the process, you can achieve a professionally leveled floor that meets your desired standards.

Using a Bubble Level

While the LP30 Laser Level is a highly accurate tool for leveling floors, using a bubble level can provide an additional layer of precision and verification. A bubble level is a handheld tool that helps identify whether a surface is perfectly level or not. Here’s how to use a bubble level to check and fine-tune the levelness of the floor:

- Select a Bubble Level: Choose a bubble level that is suitable for the size of the floor area you are leveling. Bubble levels come in various lengths and sizes, so select one that fits your needs.

- Place the Bubble Level on the Floor: Select a section of the floor and place the bubble level directly on the surface. Ensure that the bubble level is positioned parallel to the reference marks or lines you have made with the LP30 Laser Level.

- Observe the Bubble: Look closely at the bubble inside the level. It should be centered within the indicator lines. If the bubble is off-center, it indicates that the floor surface is not perfectly level at that particular point.

- Identify Areas that Require Adjustment: Identify the areas where the bubble is off-center. These areas may be higher or lower than the desired level. Make note of these locations to guide your adjustments.

- Make Fine-tuning Adjustments: Use the LP30 Laser Level to make fine-tuning adjustments to bring those areas in line with the desired level. Reposition the laser level, adjust its height or angle, and check with the bubble level again until the bubble is centered within the indicator lines.

- Recheck with the Bubble Level: After making adjustments, recheck the floor surface with the bubble level. Place it on different areas across the floor to ensure that the entire surface is level based on the bubble readings.

By using a bubble level, you can verify the levelness of the floor and make precise adjustments if needed. It is an additional tool to ensure the accuracy of the leveling process and achieve a perfectly level floor surface.

Remember to handle the bubble level carefully and ensure that it is calibrated properly. Follow the manufacturer’s instructions for using the bubble level effectively and take your time to verify the levelness of the floor accurately.

Using both the LP30 Laser Level and a bubble level in combination provides a comprehensive approach to floor leveling, ensuring a high degree of precision and accuracy in achieving a level surface.

Making Necessary Adjustments

Throughout the floor leveling process with the LP30 Laser Level, it is crucial to make necessary adjustments to ensure the desired levelness of the floor surface. These adjustments help address any deviations from the reference line and achieve a consistently level floor. Here’s how to make necessary adjustments:

- Identify Areas Requiring Adjustment: As you work across the room, keep a close eye on the laser line and observe any areas where it deviates from the reference line or where the floor surface appears uneven. These areas require adjustment.

- Consult the Reference Marks: Revisit the reference marks you have made along the laser line. Compare the laser line to these marks to determine where adjustments are needed. Areas that fall above or below the reference line should be addressed.

- Adjust the LP30 Laser Level: Use the height and angle adjustment features on the mounting bracket or tripod to move the laser level and align the laser line with the target reference marks. Ensure that the laser line is level at the desired height or levelness.

- Check with a Bubble Level: Double-check the adjustments by using a bubble level on specific areas that require attention. Place the bubble level on the floor surface and verify that the bubble is centered within the indicator lines. Make further adjustments if needed until the bubble is centered.

- Repeat as Necessary: Continuously repeat the process of identifying areas that need adjustment, making the appropriate changes with the LP30 Laser Level, and checking with a bubble level. Repeat this iterative process until the entire floor surface is consistently level.

Read more: How To Use A Laser Level To Level Ground

Finishing the Floor Leveling Process

Once you have made all the necessary adjustments and achieved a consistently level floor surface using the LP30 Laser Level, it’s time to conclude the floor leveling process. Here are the final steps to ensure a successful outcome:

- Clean Up the Area: Remove any debris, tools, or materials from the work area to prepare for the next phase of your project. Ensure that the floor surface is free from any obstructions or hazards.

- Remove the LP30 Laser Level: Carefully detach the LP30 Laser Level from the mounting bracket or tripod. Follow the manufacturer’s instructions to safely remove the device without causing any damage.

- Store the Device Properly: Clean and store the LP30 Laser Level in a safe and dry place when not in use. Store it in a case or protective covering to prevent any damage and to keep it in good working condition for future use.

By making necessary adjustments and following the proper steps for finishing the floor leveling process, you can ensure a level and even floor surface that meets your desired standards. Remember to double-check the levelness using a bubble level for additional verification.

Proper clean-up and storage of the LP30 Laser Level help maintain its longevity and ensure reliable performance in future projects. Take the time to properly care for and store the device, maximizing its lifespan.

Congratulations on successfully leveling your floor with the LP30 Laser Level! You can now proceed with confidence to the next phase of your construction or renovation project.

Cleaning Up the Area

After completing the floor leveling process with the LP30 Laser Level, it is important to clean up the area to ensure a safe and tidy space for the next stage of your construction or renovation project. Here are the steps to effectively clean up the area:

- Clear Debris and Tools: Begin by removing any debris, tools, or materials from the work area. This includes discarded leveling compounds, empty packaging, and any other items that are no longer needed. Dispose of them properly or store them away for future use.

- Vacuum or Sweep the Floor: Use a vacuum cleaner or broom to thoroughly clean the floor surface. Remove any loose dirt, dust, or small particles that may have accumulated during the leveling process. Ensure that the floor is free from debris or any obstacles that could interfere with the installation of flooring materials.

- Check for Residue or Spills: Inspect the floor surface for any residue or spills that may have occurred during the leveling process. Clean up any leveling compounds or other substances that may have accidentally spilled or left residue on the floor. Use appropriate cleaning solutions and tools as needed.

- Inspect the Area: Take a moment to inspect the entire area for any overlooked items, tools, or potential hazards. Look out for loose nails, screws, or other sharp objects that may pose a risk to safety. Ensure that the work area is well organized and safe for further work or construction activities.

Cleaning up the area after floor leveling is essential for a smooth transition to the next phase of your project. A clean and organized workspace promotes efficiency and enhances safety during subsequent tasks.

Remember to dispose of any waste materials properly, following local regulations and guidelines. Store your tools, including the LP30 Laser Level, in a designated area or case to keep them secure and ready for future use.

By taking the time to clean up the area, you create a more comfortable and productive environment for your construction or renovation project. With a clean slate, you can proceed with confidence to the next stage and enjoy the benefits of your level and even floor surface.

Removing the LP30 Laser Level

Once you have completed the floor leveling process with the LP30 Laser Level, it is important to remove the device properly to ensure its safety and longevity. Proper removal and storage of the laser level will help maintain its functionality for future use. Here are the steps to effectively remove the LP30 Laser Level:

- Power Off the Device: Before removing the LP30 Laser Level, make sure to power it off. Locate the power button on the device and press it to turn off the laser level. This will prevent any accidental activation and conserves battery life.

- Detach from the Mounting Bracket or Tripod: Disengage the LP30 Laser Level from the mounting bracket or tripod you have used during the floor leveling process. Follow the manufacturer’s instructions to safely remove the device without causing any damage. This usually involves loosening screws, levers, or quick-release mechanisms.

- Handle with Care: Use caution when handling the LP30 Laser Level. Avoid dropping or knocking the device against hard surfaces, as this can result in damage to the laser technology or internal components. Treat the device delicately to maintain its accuracy and functionality.

- Wipe Clean: Before stowing away the LP30 Laser Level, wipe it clean with a soft, dry cloth to remove any dust or debris that may have accumulated during use. Cleaning the device will help keep it in good condition and prevent foreign particles from affecting its performance.

- Securely Store the Laser Level: Once clean, store the LP30 Laser Level in a safe and appropriate location. If your device came with a protective case or pouch, use it to store the laser level. This will safeguard it from potential damage and keep it protected from dust, moisture, and accidental impacts.

Properly removing and storing the LP30 Laser Level ensures that it remains in optimum condition for future use. Keeping it clean, secure, and well-protected will extend its lifespan and preserve its functionality for your next flooring project or any other tasks that require precise level measurement.

Remember to keep the LP30 Laser Level in a designated area where it is easily accessible when needed. Store it away from extreme temperatures, direct sunlight, and moisture to prevent any potential damage.

By following these steps, you can safely and effectively remove the LP30 Laser Level, keeping it in optimal condition for accurate floor leveling in future projects.

Storing the Device Properly

Properly storing the LP30 Laser Level is essential for its longevity and continued performance. By storing the device correctly, you can ensure that it remains in optimal condition, ready for use whenever you need it. Here are the steps to properly store the LP30 Laser Level:

- Clean the Device: Before storing the LP30 Laser Level, ensure that it is clean and free from any dust, debris, or residue. Use a soft, dry cloth to wipe down the device and remove any particles that may have accumulated during use.

- Inspect for Damage: Take a moment to inspect the LP30 Laser Level for any signs of damage or wear. Check the exterior, buttons, lenses, and any other components for any visible issues. If any damage is found, address it or contact the manufacturer for repair or replacement options.

- Protective Case or Pouch: If your LP30 Laser Level came with a protective case or pouch, use it to store the device. The case or pouch will shield the device from dust, moisture, and accidental impacts, preserving its integrity and functionality.

- Safe and Dry Location: Find a safe and dry location to store the LP30 Laser Level. Choose a spot where it won’t be exposed to extreme temperatures, direct sunlight, or moisture. Avoid storing it in places where it may be subject to accidental damage or fall from a high surface.

- Keep Accessories Together: If the LP30 Laser Level has any accessories, such as mounting brackets or batteries, store them together with the device. Keeping all the components in one place ensures that everything is readily available when you need to use the laser level again.

Read more: How To Laser Level A Floor With GLL 2

Conclusion

The LP30 Laser Level is a valuable tool for accurately leveling floors and other surfaces. By following the proper steps for storage and maintenance, you can ensure that the device remains in optimal condition and ready to deliver precise measurements in any future projects.

From cleaning the device to inspecting for any damage and storing it in a safe and dry location, every step contributes to the longevity and performance of the LP30 Laser Level. By dedicating a little time and attention to proper storage, you can trust that your device will continue to provide accurate and reliable level measurements for years to come.

Remember to refer to the manufacturer’s instructions for any specific guidelines related to storage and maintenance of your LP30 Laser Level. By following these guidelines and implementing the recommended storage practices, you can enjoy the benefits of a well-preserved and dependable device whenever you need to level surfaces in your construction or renovation projects.

Properly stored and maintained, your LP30 Laser Level will be a trusted tool to achieve precise and professional-level measurements, helping you create accurate and level surfaces in your various projects.

Frequently Asked Questions about How To Use A LP30 Laser Level To Level Floor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use A LP30 Laser Level To Level Floor”