Home>Articles>Build Kegerator From Chest Freezer + How To Keep Dry

Articles

Build Kegerator From Chest Freezer + How To Keep Dry

Modified: February 26, 2024

Learn how to build a kegerator from a chest freezer and find out the best ways to keep it dry with helpful articles.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Are you tired of constantly running to the fridge for a cold beer during those hot summer days? If so, then building a kegerator from a chest freezer might be the perfect project for you. Not only will it keep your beer chilled to the perfect temperature, but it will also give you the convenience of pouring a glass straight from the tap.

Building a kegerator might seem like a daunting task, but with the right steps and materials, it can be a rewarding and enjoyable project. In this article, we will guide you through the process of building your own kegerator from a chest freezer, and we will also provide tips on how to keep it dry to ensure the longevity of your beer.

Before we dive into the step-by-step instructions, it’s important to understand the benefits of building a kegerator. First and foremost, it allows you to have fresh, draft beer right at home. There’s nothing quite like the taste and experience of pouring your own beer from a tap. Additionally, a kegerator can help you save money in the long run. Buying kegs of beer instead of individual bottles or cans can significantly reduce your beer expenses.

Now that we’ve covered the basics, let’s move on to the first step: choosing the right chest freezer for your kegerator.

Key Takeaways:

- Building a kegerator from a chest freezer is a rewarding DIY project that provides the convenience of having cold beer on tap at home, saving money, and enjoying a true pub-like experience.

- Proper maintenance, including testing, cleaning, and monitoring temperature and humidity levels, is essential for ensuring the longevity of a kegerator and the quality of the beer it dispenses.

Read more: How To Build A Freezer Kegerator

Step 1: Choosing the Right Chest Freezer

The first and most important step in building a kegerator from a chest freezer is selecting the right chest freezer to convert. Here are a few key factors to consider when making your choice:

Size: Determine how many kegs you want to fit inside the kegerator. Most chest freezers come in a range of sizes, so make sure to choose one that will accommodate your desired number of kegs plus any additional equipment you plan to install, such as CO2 tanks and regulators.

Temperature Range: Check the temperature range of the chest freezer. Ideally, you want a model that can maintain temperatures between 36 to 40 degrees Fahrenheit (2 to 4 degrees Celsius) for optimal beer storage. Some chest freezers have temperature controls that allow you to fine-tune the cooling, while others may require an external temperature controller.

Energy Efficiency: Look for an energy-efficient chest freezer to minimize operational costs. Energy Star-rated models are an excellent choice as they consume less electricity and are designed to conserve energy.

Accessibility: Consider the ease of access to your kegs when selecting a chest freezer. Look for models with a removable basket or shelves that allow you to organize and retrieve your kegs conveniently. Also, check if the lid can fully open without obstruction, giving you ample space to install the tap system.

Budget: Set a budget for your kegerator project and look for a chest freezer that aligns with your financial limitations. While it’s tempting to go for the cheapest option, remember that investing in a high-quality chest freezer can ensure better temperature control and longevity for your kegerator.

Once you’ve taken these factors into account, you should have a good idea of the chest freezer that will best suit your needs. In the next step, we will gather the materials and tools necessary for building your kegerator from the chosen chest freezer.

Step 2: Gathering Materials and Tools

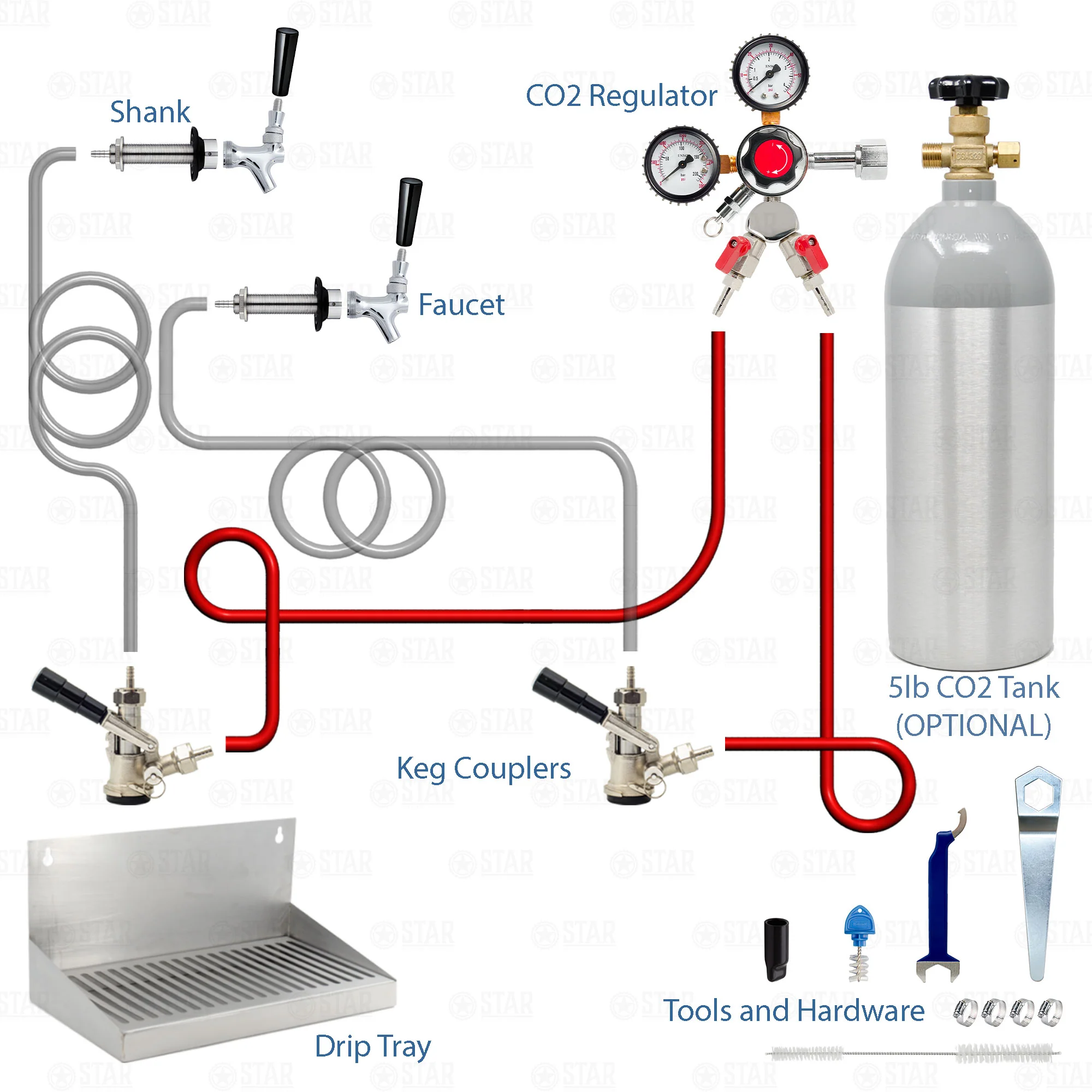

Once you have chosen the right chest freezer for your kegerator, it’s time to gather the materials and tools you will need for the conversion. Here’s a list of essential items:

Chest Freezer: The main component of your kegerator. Make sure you have the correct measurements and specifications to ensure a proper fit for your kegs and equipment.

CO2 Tank: This is necessary for pressurizing and dispensing your beer. Consider the size and capacity of the tank based on your expected usage and available space.

Regulator: The regulator controls the flow and pressure of the CO2 gas. Look for a dual-gauge regulator that allows you to monitor the pressure inside the kegerator and adjust it accordingly.

Tap Tower or Faucet: Choose a tap tower or faucet that fits your aesthetic preferences and provides easy pouring. Make sure it is compatible with the type of kegs you plan to use.

Beer Line and Disconnects: These components connect the keg to the tap tower or faucet. Ensure you have the appropriate size and type of beer line and disconnects for a secure and efficient setup.

Drip Tray: Install a drip tray beneath the tap to catch any spills and keep your kegerator clean and presentable.

Temperature Controller: If your chest freezer does not have built-in temperature control, you will need an external temperature controller to regulate the temperature within the kegerator.

Wiring and Electrical Tools: You may need electrical tools such as wire cutters, wire strippers, and electrical tape to wire the temperature controller properly.

Sealant and Insulation: Consider using weatherstripping or foam insulation strips to seal any gaps and improve the energy efficiency of your kegerator.

Additional Accessories: Depending on your preferences and requirements, you may also need additional accessories such as a CO2 manifold, keg couplers, keg cleaning supplies, and a keg brush.

Make sure to gather all these materials before proceeding to the next step. Having everything on hand will make the conversion process smoother and more efficient.

In the next step, we will guide you through the process of preparing the chest freezer for the kegerator conversion.

Step 3: Preparing the Chest Freezer

Now that you have gathered all the necessary materials and tools, it’s time to prepare the chest freezer for the kegerator conversion. Follow these steps to get started:

1. Clean the Chest Freezer: Ensure the chest freezer is clean and free from any debris or residues. Wipe down the interior and remove any shelves or baskets that may obstruct the installation of the keg and tap system.

2. Determine the Placement: Decide how you want to position the kegs inside the chest freezer. This will help you mark the location for the tap tower or faucet and plan the beer line routing. Make sure to leave enough space for the CO2 tank and regulator as well.

3. Mark and Cut Holes: Measure and mark the location for the tap tower or faucet on the lid of the chest freezer. Use a hole saw or a jigsaw to cut a hole of the appropriate size. Similarly, mark and cut smaller holes for the beer line, CO2 line, and wires for the temperature controller.

4. Install the Tap Tower or Faucet: Insert the tap tower or faucet through the hole you cut on the lid of the chest freezer. Tighten the mounting hardware to secure it in place. If using a faucet, make sure it is properly tightened and sealed.

5. Feed the Beer Line and CO2 Line: Thread the beer line and the CO2 line through their respective holes. Ensure they are long enough to reach their intended destinations within the chest freezer. Leave some slack to allow for adjustments during the final installation.

6. Apply Insulation and Sealant: Apply weatherstripping or foam insulation strips around the edges of the lid and any other areas with potential air leaks. This will help maintain the temperature stability inside the kegerator. Use sealant or silicone to seal any gaps or holes, ensuring a tight and secure seal.

7. Reassemble and Test: Reassemble any shelves or baskets that were removed earlier. Plug in the chest freezer and test its cooling capabilities. Monitor the temperature inside the unit to ensure it stays within the desired range. This will also allow you to identify any potential issues that need to be addressed before proceeding with the final installation.

By following these steps, you will have prepared the chest freezer for the kegerator conversion. In the next step, we will guide you through the process of installing the tap system.

Step 4: Installing the Tap System

With the chest freezer prepared, it’s now time to install the tap system for your kegerator. Follow these steps to complete the installation:

1. Connect the Beer Line: Attach one end of the beer line to the tap tower or faucet, and the other end to the corresponding keg coupler. Make sure the connections are secure and tight to prevent any leaks. If necessary, use clamps to ensure a tight fit.

2. Connect the CO2 Line: Connect one end of the CO2 line to the regulator and the other end to the keg coupler. Again, ensure the connections are tight and secure. Use clamps if necessary.

3. Adjust the CO2 Pressure: Adjust the pressure on the CO2 regulator according to the recommendations provided by the beer manufacturer or your personal preferences. Start with a lower pressure and gradually increase it until you achieve the desired carbonation level. Refer to the instructions provided with your regulator for guidance on adjusting the pressure.

4. Secure the Beer Line: Use zip ties or adhesive clips to secure the beer line along the interior walls of the chest freezer. Route it away from any potential obstructions or sources of heat. Ensure the line is not kinked or twisted, which could affect the flow of the beer.

5. Install the Drip Tray: Place the drip tray beneath the tap tower or faucet to catch any spills or drips. This will help keep your kegerator clean and prevent any liquid from seeping into the chest freezer.

6. Test the Tap System: Open the faucet or tap handle and check for any leaks or irregularities in the flow of beer. Adjust the CO2 pressure if necessary to achieve the desired pour. Also, check the temperature inside the kegerator to ensure it remains within the optimal range for serving cold beer.

7. Fine-tune and Adjust: Make any necessary adjustments to the tap tower, faucet, or beer line to achieve the desired pour and carbonation. This may involve adjusting the height of the tap tower, changing the length of the beer line, or making slight modifications to the CO2 pressure.

Completing these steps will ensure that your tap system is properly installed and functioning correctly. In the next step, we will discuss how to secure the CO2 tank in your kegerator.

To keep your kegerator dry, use a dehumidifier or moisture-absorbing products like silica gel packs inside the chest freezer. This will help prevent condensation and mold growth.

Read more: How To Keep A Freezer From Frosting

Step 5: Securing the CO2 Tank

Properly securing and positioning the CO2 tank is crucial for the effective and safe operation of your kegerator. Follow these steps to securely mount the CO2 tank:

1. Choose a Mounting Location: Select a suitable location inside the kegerator to mount the CO2 tank. It should be easily accessible and not interfere with the kegs or other equipment. Also, make sure the mounting location allows for proper ventilation and does not obstruct any necessary airflow.

2. Install a CO2 Tank Holder: Purchase a CO2 tank holder or bracket that is compatible with the size of your CO2 tank. These holders are typically made from metal and have adjustable straps or clamps to securely hold the tank in place.

3. Determine the Mounting Position: Determine the best position for the CO2 tank holder inside the kegerator. It is typically mounted on one of the side walls or the back wall, depending on the available space and accessibility.

4. Mark and Drill Holes: Use a marker or pencil to mark the locations where you will drill holes to mount the CO2 tank holder. Ensure that the holes are evenly spaced and aligned for proper installation.

5. Secure the CO2 Tank Holder: Use screws or bolts (appropriate for the material of the kegerator walls) to secure the CO2 tank holder in place. Make sure the screws or bolts are tight enough to hold the holder securely, but not too tight to damage the walls of the kegerator.

6. Place the CO2 Tank: Insert the CO2 tank into the holder and make sure it is stable and secure. Double-check that the tank is properly attached to the holder and won’t move or fall out easily.

7. Route and Secure the CO2 Line: Route the CO2 line from the regulator to the keg coupler while avoiding any obstructions or sharp edges that could cause damage. Use zip ties or adhesive clips to secure the CO2 line along the interior of the kegerator walls.

8. Test the CO2 System: Open the valve on the CO2 tank to allow the gas to flow into the system. Check for any leaks and ensure that the CO2 pressure gauge on the regulator shows the desired pressure. Adjust the pressure as necessary using the regulator dial.

By following these steps, you will be able to secure the CO2 tank in your kegerator, ensuring it is positioned safely and conveniently. In the next step, we will discuss the process of wiring the temperature controller.

Step 6: Wiring the Temperature Controller

In order to accurately regulate the temperature inside your kegerator, you will need to wire a temperature controller. Here’s how to do it:

1. Choose a Location: Select a suitable location inside the kegerator to mount the temperature controller. It should be easily accessible and away from any moisture or potential spills. Also, ensure that the location allows for easy access to the temperature probe.

2. Plan the Wiring Path: Determine the path of the wires from the temperature controller to the power source and the chest freezer. Take into consideration the length of the wires and any potential obstructions.

3. Disconnect the Power: Before proceeding, make sure to unplug the chest freezer from the power source to ensure your safety.

4. Open the Control Panel: Locate the control panel of the chest freezer and open it up to access the internal wiring.

5. Connect the Temperature Controller: Depending on the type of temperature controller you have, connect the appropriate wires. Typically, you will need to connect the power supply wires (usually black and white) and the wires from the temperature probe.

6. Connect to the Power Source: Locate the power source within the chest freezer and connect the power supply wires from the temperature controller. Make sure to follow the manufacturer’s instructions or consult a professional if you’re unsure about the wiring connections.

7. Mount and Secure: Mount the temperature controller in the chosen location and secure it in place using screws or adhesive. Ensure that the wires are neatly organized and secured to prevent any tangling or interference.

8. Route the Temperature Probe: Route the temperature probe of the controller to a suitable location inside the chest freezer where it can accurately measure the temperature. Avoid placing it near the cooling coils or in direct contact with any kegs or equipment.

9. Close the Control Panel: Once you have completed the wiring connections, close the control panel of the chest freezer and secure it in place.

10. Plug in and Test: Finally, plug in the chest freezer to the power source and switch on the temperature controller. Set the desired temperature and monitor the readings on the controller’s display to ensure that the chest freezer is maintaining the desired temperature range.

By following these steps, you will be able to wire the temperature controller and ensure proper regulation of the temperature inside the kegerator. In the next step, we will discuss how to test the kegerator and make any necessary adjustments.

Step 7: Testing the Kegerator

Now that you have completed the installation and wiring process, it’s time to test your kegerator and ensure that it is functioning properly. Follow these steps to conduct a thorough testing:

1. Power On and Cool Down: Plug in the kegerator and allow it to cool down for a sufficient amount of time. This will ensure that the chest freezer reaches the desired temperature range for storing and serving beer.

2. Check Temperature Stability: Monitor the temperature inside the kegerator using the temperature controller. Ensure that the temperature remains consistent and falls within the desired range for storing and serving beer. Make any necessary adjustments to the temperature controller to maintain the proper level of cooling.

3. Test the Tap System: Open the tap or faucet and pour a glass of beer. Check the flow, carbonation level, and overall quality of the beer. Adjust the CO2 pressure if necessary to achieve the desired carbonation and pour speed.

4. Check for Leaks: Inspect all connections and fittings in the tap system for any signs of leaks. Look for any dripping or hissing sounds that could indicate a leak in the system. If you detect any leaks, tighten the connections or replace any faulty components.

5. Taste Testing: Pour yourself a beer and taste it to ensure that it meets your expectations in terms of quality, temperature, and carbonation. Enjoy the fruits of your labor and make any adjustments as needed to achieve the desired taste and experience.

6. Monitor and Record: Over the next few days, continue to monitor and record the temperature inside the kegerator, as well as the quality of the beer. Make note of any unusual fluctuations, issues with carbonation, or other concerns that may require further adjustments or maintenance.

7. Fine-tune as Needed: Based on your observations during the testing phase, fine-tune any aspects of the kegerator that need improvement. This may include adjusting the temperature controller, modifying the length of beer lines, or fine-tuning the CO2 pressure. Regularly test and taste the beer to ensure consistency and optimal performance.

Through thorough testing, you can identify and address any issues early on, ensuring that your kegerator provides the best beer-drinking experience. In the final step, we will discuss how to maintain dryness within the kegerator.

Step 8: Maintaining Dryness

Maintaining dryness within your kegerator is crucial to ensure the longevity of your beer and the overall cleanliness of the system. Follow these steps to prevent excess moisture and condensation:

1. Use a Dehumidifier: Consider using a dehumidifier inside the kegerator to extract moisture from the air. Excess humidity can lead to condensation and the formation of mold or mildew. Place the dehumidifier in a suitable location within the kegerator and monitor it regularly to ensure its effectiveness.

2. Check Seals and Insulation: Regularly inspect the seals and insulation around the chest freezer lid, tap tower, and any other openings. Ensure that they are properly sealed and free from any cracks or gaps. Use weatherstripping or foam insulation strips to seal any areas that may be prone to air leaks.

3. Watch for Leaks: Periodically check for any leaks in the tap lines, CO2 lines, or other connections. Leaks not only waste beer but can also contribute to excess moisture within the kegerator. Make sure all connections are secure and tighten them if necessary. Replace any faulty components or damaged seals.

4. Clean Regularly: Regularly clean the kegerator to prevent the buildup of residue or spills that could contribute to excess moisture. Remove any empty kegs and clean the interior with a mild detergent or specialized keg cleaner. Wipe down the tap tower, drip tray, and all other components to ensure cleanliness and prevent mold or bacterial growth.

5. Empty and Dry the Drip Tray: Empty the drip tray regularly to prevent standing water or liquid buildup. Wipe it down and allow it to air dry completely before placing it back in the kegerator. Consider using an absorbent mat or liner in the drip tray to help collect any spills or drips.

6. Monitor Temperature and Humidity: Keep an eye on the temperature and humidity levels inside the kegerator using the temperature controller and a hygrometer. Ensure that the temperature remains steady in the desired range and that the humidity level is within an acceptable range to prevent excessive moisture.

7. Inspect CO2 Tank: Regularly check the CO2 tank for any signs of excess moisture or condensation. If you notice any moisture on the tank or regulator, address the issue promptly to prevent damage to the equipment. Wipe down any moisture and ensure that the tank is properly sealed.

8. Maintain Proper Airflow: Ensure that there is proper airflow within the kegerator to help prevent the buildup of moisture. Avoid placing items directly in front of any vents or obstructing the circulation of air. Check for any debris blocking air intake or exhaust areas and clear them as necessary.

By following these steps and maintaining proper moisture control, you can ensure the freshness and quality of your beer while prolonging the lifespan of your kegerator. Regular maintenance and attention to detail will help you enjoy your favorite brews for years to come.

With the completion of Step 8, you have successfully built your own kegerator from a chest freezer and learned how to maintain its dryness. Cheers to your new kegerator and the joy of pouring fresh draft beer at home!

If you have any questions or require further assistance, feel free to reach out. Happy brewing!

Read more: How To Keep Hanging Baskets From Drying Out

Conclusion

Congratulations! You have successfully built your very own kegerator from a chest freezer. By following the step-by-step process outlined in this article, you have transformed a simple freezer into a fully functional tap system that allows you to pour refreshing draft beer right at home.

Building a kegerator not only provides the convenience of having cold beer on tap, but it also offers the opportunity to save money and enjoy a true pub-like experience in the comfort of your own space. Plus, the satisfaction of completing this DIY project is second to none.

Throughout the article, we discussed the importance of choosing the right chest freezer, gathering the necessary materials and tools, preparing the chest freezer, installing the tap system, securing the CO2 tank, wiring the temperature controller, testing the kegerator, and maintaining dryness. Each step is crucial in creating a functional and efficient kegerator system.

Remember to always test the kegerator and make any necessary adjustments to achieve optimal performance. Regular maintenance, such as cleaning and monitoring temperature and humidity levels, will help ensure the longevity of your kegerator and the quality of your beer.

Now, it’s time to sit back, relax, and enjoy the fruits of your labor. Invite friends over, host parties, and savor the experience of pouring your favorite beers on tap. Make memories and create moments that will become the envy of your beer-loving friends.

If you have any questions or need further assistance, don’t hesitate to refer back to this article or consult additional resources. Building a kegerator is a fun and rewarding endeavor that opens up a world of possibilities for your beer enjoyment.

So, raise a glass to your newfound kegerator, and here’s to many memorable moments shared over cold, refreshing beers!

Frequently Asked Questions about Build Kegerator From Chest Freezer + How To Keep Dry

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Build Kegerator From Chest Freezer + How To Keep Dry”