Home>Articles>How To Install Insulation On Exterior Walls The Right Way

Articles

How To Install Insulation On Exterior Walls The Right Way

Modified: January 23, 2024

Looking for informative articles on how to install insulation on exterior walls? Learn the right way to do it with our helpful tips and guides.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the comprehensive guide on how to install insulation on exterior walls the right way. Proper insulation is crucial for maintaining energy efficiency, controlling indoor temperature, and reducing energy costs. By insulating your exterior walls, you can create a more comfortable living environment and save on your energy bills.

Installing insulation on exterior walls involves more than just stuffing material into the empty spaces. It requires careful assessment, choosing the right insulation material, preparing the wall surface, and proper installation techniques. In this article, we will walk you through a step-by-step process to help you install insulation on your exterior walls effectively.

Before we dive into the installation process, it’s important to note that each home may have unique requirements, depending on factors such as climate, type of construction, and local building codes. It is always recommended to consult with a professional or do thorough research before starting any insulation project.

Now, let’s get started with the first step: assessing the wall structure.

Key Takeaways:

- Properly assessing the wall structure and choosing the right insulation material are crucial steps in ensuring effective and long-lasting insulation on exterior walls.

- Thoroughly preparing the wall surface, installing insulation with care, and sealing gaps and air leaks are essential for maximizing energy efficiency and creating a comfortable living environment.

Step 1: Assessing the Wall Structure

Before you begin the insulation installation process, it’s important to assess the structure of your exterior walls. This step will help you identify any potential issues or areas that require special attention.

Start by examining the type of wall construction in your home. Common types include wood frame, masonry, or concrete block. Each type may have specific considerations when it comes to insulation installation.

Determine if there are any existing insulation materials in the walls. Older homes might have outdated or insufficient insulation, while newer constructions may already have a layer of insulation.

Check for any signs of damage, such as water leaks, rot, or pests. These issues should be addressed and resolved before proceeding with insulation installation.

Measure the thickness of the wall cavities. This measurement will help you determine the appropriate insulation material and its required R-value. The R-value indicates the insulation’s effectiveness in resisting heat flow, with higher values providing better insulation performance.

If your exterior walls have existing insulation, assess its condition. Insulation materials can deteriorate over time, lose their effectiveness, and develop mold or pest infestations. In such cases, it is recommended to remove and replace the old insulation.

Consider the climate and local building codes in your area. Some regions have specific requirements for insulation materials and installation techniques to ensure optimum energy efficiency and building performance.

Lastly, evaluate any obstructions or obstacles in the wall cavities, such as electrical wiring, plumbing, or HVAC components. These elements may affect the installation process and require careful consideration and planning.

By thoroughly assessing the wall structure, you can identify any potential challenges and make informed decisions during the insulation installation process. This will help ensure the effectiveness and longevity of your insulation system.

Step 2: Choosing the Right Insulation Material

Once you have assessed the wall structure, the next step is to choose the right insulation material for your exterior walls. There are several types of insulation materials available, each with its own set of advantages and considerations.

Here are some common insulation materials to consider:

- Fiberglass: This is one of the most widely used insulation materials. It consists of fine glass fibers and is available in batts, rolls, or loose-fill. Fiberglass is affordable, easy to install, and provides good thermal resistance. However, it can irritate the skin and respiratory system, so proper protective gear should be worn during installation.

- Mineral Wool: Also known as rock wool or slag wool, mineral wool is made from minerals such as basalt or slag. It has similar properties to fiberglass insulation but offers better soundproofing and fire resistance. Mineral wool is moisture-resistant and does not support mold growth.

- Spray Foam: Spray foam insulation is applied as a liquid that expands and hardens into a solid foam. It provides excellent insulation, air sealing, and moisture barrier properties. Spray foam is commonly used in hard-to-reach areas or irregularly shaped wall cavities. However, it requires professional installation due to its specific application process.

- Cellulose: Cellulose insulation is made from recycled paper treated with fire-retardant chemicals. It is a cost-effective option, particularly for retrofitting existing walls. Cellulose provides good thermal performance and soundproofing. However, it may settle over time, reducing its effectiveness, and requires proper moisture management.

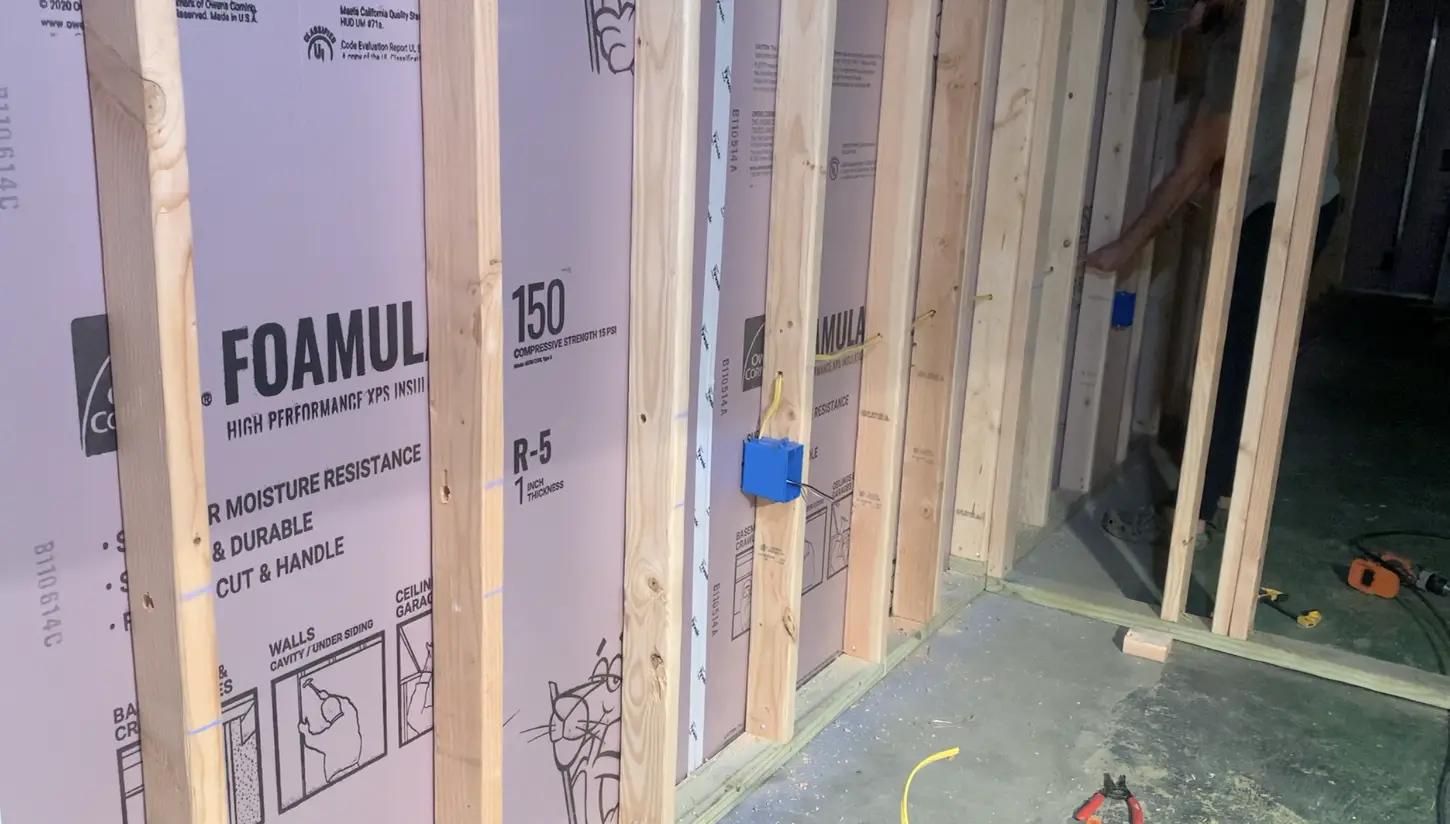

- Rigid Foam: Rigid foam insulation boards are made from polystyrene or polyisocyanurate. They offer high thermal resistance and can be easily cut to fit the wall cavities. Rigid foam is commonly used for exterior insulation systems (EIFS) or insulation under siding. However, it is more expensive compared to other insulation materials.

Consider factors such as the desired level of insulation, cost, installation method, fire resistance, moisture management, and local building codes when choosing the right insulation material for your exterior walls.

It is also recommended to consult with insulation professionals or contractors who can provide expert advice based on your specific needs and the characteristics of your home.

By selecting the appropriate insulation material, you can ensure long-lasting insulation performance and energy efficiency for your exterior walls.

Step 3: Preparing the Wall Surface

Before you begin the actual installation of insulation, it is essential to prepare the wall surface to ensure proper adhesion and a smooth installation process.

Here are some steps to follow when preparing the wall surface:

- Clean the wall: Remove any dirt, dust, or debris from the wall surface. This can be done by using a broom, vacuum, or a damp cloth. A clean surface will allow the insulation material to properly adhere to the walls.

- Repair any damage: Take the time to inspect the wall surface for any cracks, holes, or damage. Patch up these areas using the appropriate repair materials. Properly sealing these openings will prevent air leaks and ensure the effectiveness of the insulation.

- Address moisture issues: Moisture can affect the performance and durability of insulation. Identify and fix any water leaks or moisture problems on the wall surface. Install proper moisture barriers or waterproofing materials if necessary.

- Seal gaps and joints: Use caulk or weatherstripping to seal any gaps, joints, or penetrations in the wall. These areas can be a significant source of air leakage, impacting the insulation’s effectiveness. Pay attention to areas around windows, doors, electrical outlets, and plumbing penetrations.

- Remove obstacles: Clear the wall surface of any obstructions or obstacles that may hinder the installation process. This includes removing outlet covers, light switch plates, and any other fixtures attached to the wall.

- Ensure a level surface: Insulation materials need a flat and even surface for proper installation. Use a level to ensure that the wall surface is straight and level. If necessary, make any adjustments to achieve a smooth and uniform surface.

Preparing the wall surface is a crucial step in the insulation installation process. It sets the foundation for a successful and long-lasting insulation system. Taking the time to address any issues and create a clean and stable surface will maximize the effectiveness and energy efficiency of the insulation on your exterior walls.

Step 4: Installing the Insulation

With the wall surface prepared, it’s time to install the insulation on your exterior walls. The installation process may vary depending on the type of insulation material you’ve chosen. Here, we provide a general overview of the installation steps:

- Measure and cut: Measure the length and width of the wall cavity where the insulation will be installed. Use those measurements to cut the insulation material to the appropriate size. Ensure a snug fit to maximize insulation performance.

- Insert the insulation: Carefully place the insulation material into the wall cavity. In the case of batt or roll insulation, press it firmly between the studs or joists, ensuring it fills the entire cavity without compressing it. For loose-fill insulation, use a blower machine to blow the insulation into the cavity, achieving an even distribution.

- Secure the insulation: If necessary, use insulation supports or hangers to secure the insulation in place and prevent it from sagging. This is particularly important for vertical installations or areas with gravity resistance.

- Continue the installation: Repeat the process of measuring, cutting, and inserting the insulation material until the entire wall cavity is filled. Take care not to leave any gaps or spaces, as they can compromise the insulation’s effectiveness.

- Handle obstacles: When encountering obstacles like wiring or plumbing, carefully work the insulation around them, ensuring they are covered and insulated properly. Use insulation baffles or chutes to maintain proper ventilation in attics or crawlspaces.

- Avoid compression: Be cautious not to compress the insulation material. Compressing the insulation reduces its effectiveness and lowers its insulation R-value. Allow for sufficient air circulation within the wall system.

Throughout the installation process, it’s crucial to follow the manufacturer’s instructions and any applicable building codes. Pay attention to safety precautions, especially when working with insulation materials that may cause skin irritation or respiratory issues.

If you’re unsure about the installation process or if you have a complex wall structure, it’s advisable to seek professional assistance. Insulation professionals can ensure proper installation, minimize potential issues, and maximize the overall efficiency of your insulation system.

Remember, properly installed insulation plays a vital role in creating a more energy-efficient home, reducing heat loss or gain, and improving thermal comfort.

When installing insulation on exterior walls, make sure to properly seal any gaps or cracks to prevent air leakage and maximize the insulation’s effectiveness. Use a combination of insulation materials to achieve the desired R-value for your climate.

Read more: How To Add Insulation To Exterior Walls

Step 5: Properly Sealing Gaps and Air Leaks

After installing the insulation on your exterior walls, it is essential to properly seal any gaps and air leaks. These gaps and leaks can significantly reduce the effectiveness of your insulation and compromise energy efficiency.

Here are some key steps to follow when sealing gaps and air leaks:

- Identify potential areas: Inspect the walls carefully to identify any gaps, cracks, or openings where air leakage may occur. Common areas to check include window and door frames, wall penetrations, electrical outlets, and baseboards.

- Caulk and weatherstrip: Use caulk or weatherstripping to seal gaps around windows and doors. Apply caulk to any cracks or openings in the wall surface. Weatherstripping can be installed around windows and doors to create a tight seal when closed.

- Seal electrical outlets: Install foam gaskets behind electrical outlet and switch plates. These gaskets help provide insulation and prevent air leakage through outlets and switches.

- Seal wall penetrations: Pay attention to any pipes, wiring, or other penetrations in the wall. Use appropriate sealants or fireproof caulking to seal around these penetrations. This prevents air leakage and helps maintain the integrity of the insulation.

- Insulate attic hatches and access panels: Attic hatches and access panels can be major sources of air leakage. Ensure they are properly insulated and sealed with weatherstripping or foam tape.

- Test for air leakage: After sealing the gaps, conduct a blower door test to identify any remaining air leaks. A blower door test measures the amount of air leakage in your home and helps pinpoint specific areas that may require additional sealing.

- Regular maintenance: Regularly inspect your exterior walls for any signs of new gaps or air leaks. Address them promptly to maintain the effectiveness of your insulation and optimize energy efficiency.

Properly sealing gaps and air leaks ensures that your insulation performs at its best, minimizes heat transfer, and enhances energy efficiency. This step helps create a more comfortable indoor environment and reduces energy costs.

If you are unsure about the sealing process or if you have a complex wall structure, consider consulting with a professional insulation contractor. They can provide expert advice, perform a thorough air leakage assessment, and recommend appropriate sealing techniques specific to your home.

Step 6: Installing Vapor Barriers (If Required)

Installing a vapor barrier is an important step in some climates and building conditions to prevent moisture from reaching and damaging the insulation on your exterior walls. Vapor barriers are specifically designed to control the movement of moisture vapor, protecting the integrity of the insulation system.

Here are the key considerations and steps for installing vapor barriers:

- Determine if a vapor barrier is necessary: In some climates, vapor barriers are not required, while in others they are essential. Consult local building codes, climate conditions, and insulation professionals to determine if a vapor barrier is recommended for your area.

- Choose the appropriate vapor barrier: Vapor barriers are available in different materials, such as polyethylene sheeting or plastic film. Select a barrier that meets the required specifications for your specific insulation system.

- Install the vapor barrier: The vapor barrier should be installed on the warm side of the insulation. In cold climates, the warm side is typically facing the interior of the building. Ensure that the barrier is spread out evenly, covering the entire insulated wall surface.

- Seal the seams: To create an effective barrier, seal the seams of the vapor barrier using tape or adhesive. This will prevent moisture from penetrating through the gaps and compromising the insulation’s performance.

- Avoid punctures or rips: Take care to avoid puncturing or ripping the vapor barrier during the installation process. Any damage to the barrier can compromise its effectiveness in preventing moisture vapor transmission.

- Integrate with other components: Ensure that the vapor barrier is integrated with other building components such as windows, doors, and electrical penetrations. Properly seal around these areas to maintain a continuous barrier.

- Follow manufacturer’s instructions: Always refer to the manufacturer’s instructions and any applicable building codes when installing a vapor barrier. Adhere to recommended installation techniques to achieve the best results.

It’s worth noting that vapor barriers may not be necessary in all climates or with all insulation materials. In some cases, alternative moisture control strategies such as breathable insulation or proper ventilation may be more appropriate. Consulting with insulation professionals or building experts will help determine the best approach for your specific circumstances.

Installing a vapor barrier, if required, helps protect the insulation from moisture-related damage, ensuring its long-term performance and energy efficiency.

Step 7: Applying a Protective Exterior Finish

After insulating and sealing your exterior walls, it’s important to apply a protective exterior finish to enhance the durability and appearance of the insulation. The right finish can provide an extra layer of protection against weather elements and help prolong the life of your insulation system.

Here are the key steps for applying a protective exterior finish:

- Select an appropriate finish: Choose a finish that is compatible with the insulation material, weather conditions in your area, and the aesthetic you desire. Common options include exterior paint, siding, stucco, or brick veneer. Consult with professionals or refer to manufacturer recommendations for the best choice.

- Prepare the wall surface: Ensure the wall surface is clean, dry, and free from any debris. Remove any loose or peeling paint, repair damaged areas, and sand rough spots to create a smooth and even surface for the finish.

- Apply a moisture barrier (if necessary): In specific climates or building conditions, it may be necessary to apply a moisture barrier between the insulation and the exterior finish. This barrier helps prevent moisture from infiltrating the insulation and causing damage. Follow manufacturer instructions and building codes for proper installation.

- Apply the finish: Depending on the chosen finish, follow the recommended application techniques. This could involve painting, installing siding, applying stucco, or laying brick veneer. Take care to apply the finish evenly and cover the entire exterior wall surface.

- Allow for proper curing and drying: Give the applied finish time to properly cure and dry according to manufacturer recommendations. This will ensure its effectiveness and longevity in protecting the insulation and enhancing the overall appearance of your exterior walls.

- Maintain the finish: Regularly inspect the exterior finish for any signs of damage or deterioration. Perform necessary touch-ups or repairs as needed to maintain the protective properties of the finish and the overall integrity of the insulation system.

Applying a protective exterior finish not only adds aesthetic value to your home but also helps shield the insulation from weather elements, UV radiation, and potential damage. A well-maintained and properly applied exterior finish contributes to the long-term performance and energy efficiency of your insulation system.

For specific guidance on applying a protective exterior finish, consult professionals or refer to detailed manufacturer instructions to ensure a successful installation.

Step 8: Final Check and Inspection

The final step in the insulation installation process is conducting a thorough check and inspection to ensure everything is in place and functioning as intended. This step allows you to address any potential issues and make necessary adjustments before considering the project complete.

Here are the key tasks to perform during the final check and inspection:

- Visually inspect the insulation: Carefully examine the installed insulation to ensure it covers the entire wall cavity without any gaps or compression. Look for any areas that may require additional insulation or adjustments.

- Check for proper sealing: Verify that all gaps, cracks, and air leaks have been properly sealed throughout the installation process. Make sure the insulation system is airtight to prevent heat loss or gain.

- Test for air leakage: Conduct a blower door test or use a smoke pencil to identify any remaining air leaks that may have been missed during the sealing process. Address these leaks promptly to optimize energy efficiency.

- Inspect vapor barriers (if installed): If a vapor barrier was installed, check for any damage, tears, or gaps in its coverage. Ensure it is properly sealed and functioning as an effective moisture barrier.

- Verify compliance with building codes and regulations: Double-check that the insulation installation meets all applicable building codes and regulations specific to your area. This ensures compliance and ensures the safety and efficiency of your insulation system.

- Perform a thermal evaluation: Use thermal imaging or other tools to evaluate the effectiveness of the insulation. Look for any thermal bridging or areas of heat transfer that may require additional insulation or attention.

- Document and record the installation: Keep a detailed record of the insulation installation process, including the materials used, techniques employed, and maintenance recommendations. This documentation can be useful for future reference and potential audits.

By performing a final check and inspection, you can have confidence that your insulation system is properly installed and functioning as intended. This step helps ensure the maximum energy efficiency, thermal comfort, and longevity of your exterior wall insulation.

If you discover any issues during the inspection, consult with insulation professionals or contractors who can provide further guidance and assistance in resolving the problems.

Congratulations! With the final check and inspection complete, you have successfully installed insulation on your exterior walls, creating a more energy-efficient and comfortable living space.

Read more: What Insulation To Use For Exterior Walls

Conclusion

Installing insulation on exterior walls is a crucial step in creating a more energy-efficient and comfortable home. By following the right steps and techniques, you can enhance insulation performance, reduce energy costs, and improve indoor comfort levels.

In this comprehensive guide, we have walked you through the process of installing insulation on exterior walls the right way. We started by assessing the wall structure, choosing the appropriate insulation material, and preparing the wall surface. We then covered the installation of insulation, sealing gaps and air leaks, installing vapor barriers if required, applying a protective exterior finish, and performing a final check and inspection.

Throughout the installation process, it is important to consult local building codes, follow manufacturer instructions, and consider professional expertise. Every home has unique requirements, and it’s crucial to tailor the insulation approach accordingly.

Properly insulating exterior walls can reduce heat loss or gain, improve indoor temperature control, and lower energy consumption. It also contributes to environmental sustainability by reducing greenhouse gas emissions and reliance on fossil fuels.

Remember to maintain and monitor your insulation system regularly. Check for any signs of damage, moisture issues, or air leaks, and address them promptly to ensure the long-term performance of the insulation and optimize energy efficiency.

Whether you’re a homeowner embarking on a DIY project or working with professionals, the installation of insulation on exterior walls is a worthwhile investment. It not only provides immediate benefits in terms of energy savings but also enhances the overall comfort and value of your home.

By following the steps outlined in this guide and considering the unique needs of your home, you’ll be well on your way to achieving a well-insulated, energy-efficient, and comfortable living space for years to come.

Frequently Asked Questions about How To Install Insulation On Exterior Walls The Right Way

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Install Insulation On Exterior Walls The Right Way”