Articles

How To Protect Electrical Cord Over Roadway

Modified: August 16, 2024

Discover effective ways to protect electrical cords when crossing roadways with these informative articles. Learn about safety measures and best practices to ensure your cords stay secure and prevent accidents.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on how to protect electrical cords over roadways. In today’s modern world, the need for temporary power supply solutions has become increasingly common, especially in industries such as construction, event management, and film production. While utilizing electrical cords may be essential to power equipment and lighting in these situations, it is crucial to prioritize safety by implementing protective measures.

In this article, we will highlight the importance of safeguarding electrical cords when they cross roadways. We’ll also explore the potential hazards of leaving cords unprotected and discuss various types of protective measures that can be employed. Additionally, we’ll guide you on how to choose the right protective cover for your electrical cords, as well as provide insights on proper installation and regular maintenance.

Protecting electrical cords over roadways is of utmost importance to prevent accidents, ensure uninterrupted power supply, and comply with safety regulations. By understanding the risks involved and implementing appropriate protective measures, you can create a safe working environment and minimize potential hazards.

Let’s dive into the details of how you can effectively protect electrical cords over roadways and keep your operations running smoothly and safely.

Key Takeaways:

- Prioritize safety and prevent accidents by protecting electrical cords over roadways. Choose the right protective cover, install it properly, and maintain it regularly to create a safe working environment.

- Protecting electrical cords over roadways is crucial for preventing tripping hazards, damage to cords, and compliance with safety regulations. Choose the right protective measures and prioritize safety for successful project execution.

Read more: How To Tie An Electrical Cord

Importance of Protecting Electrical Cords Over Roadways

Protecting electrical cords over roadways is not just a matter of compliance with safety regulations; it is a crucial step in ensuring the safety of workers, pedestrians, and the overall success of any project involving temporary power supply.

One of the primary reasons for protecting electrical cords over roadways is to prevent tripping hazards. When cords are left exposed, they can pose a significant risk to pedestrians, workers, and even vehicles passing by. A simple trip over an unprotected cord can result in injuries, delays, and legal liabilities.

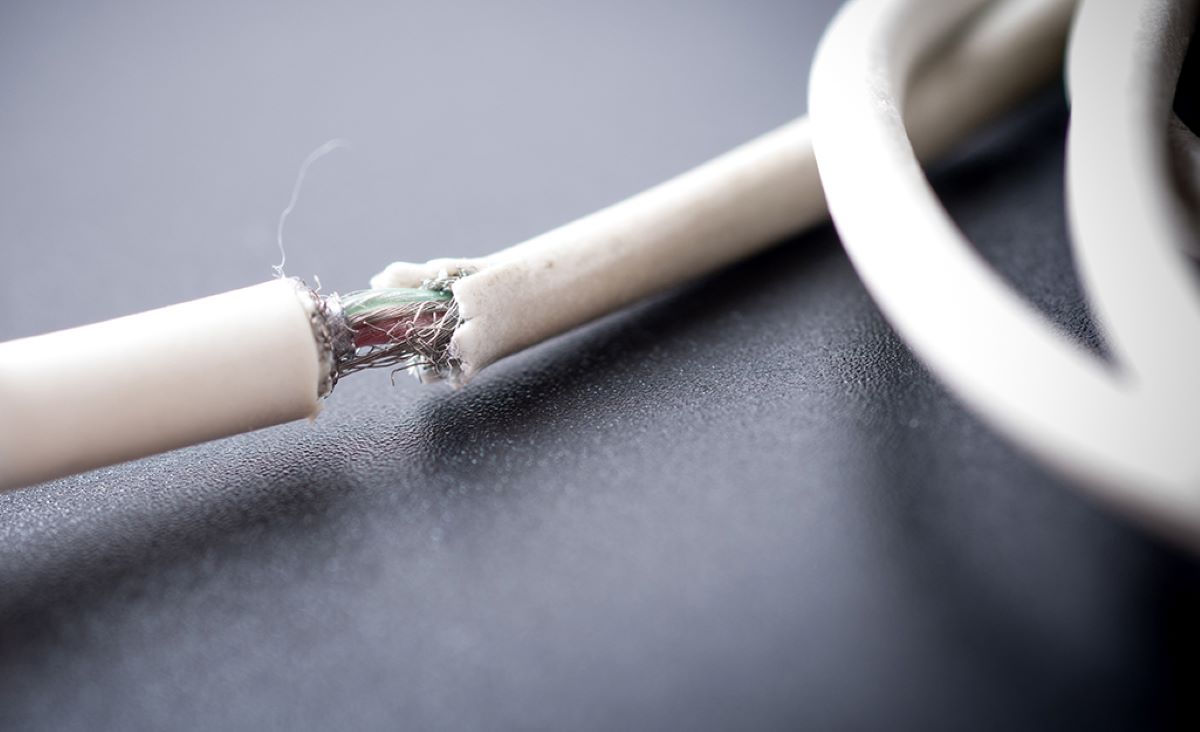

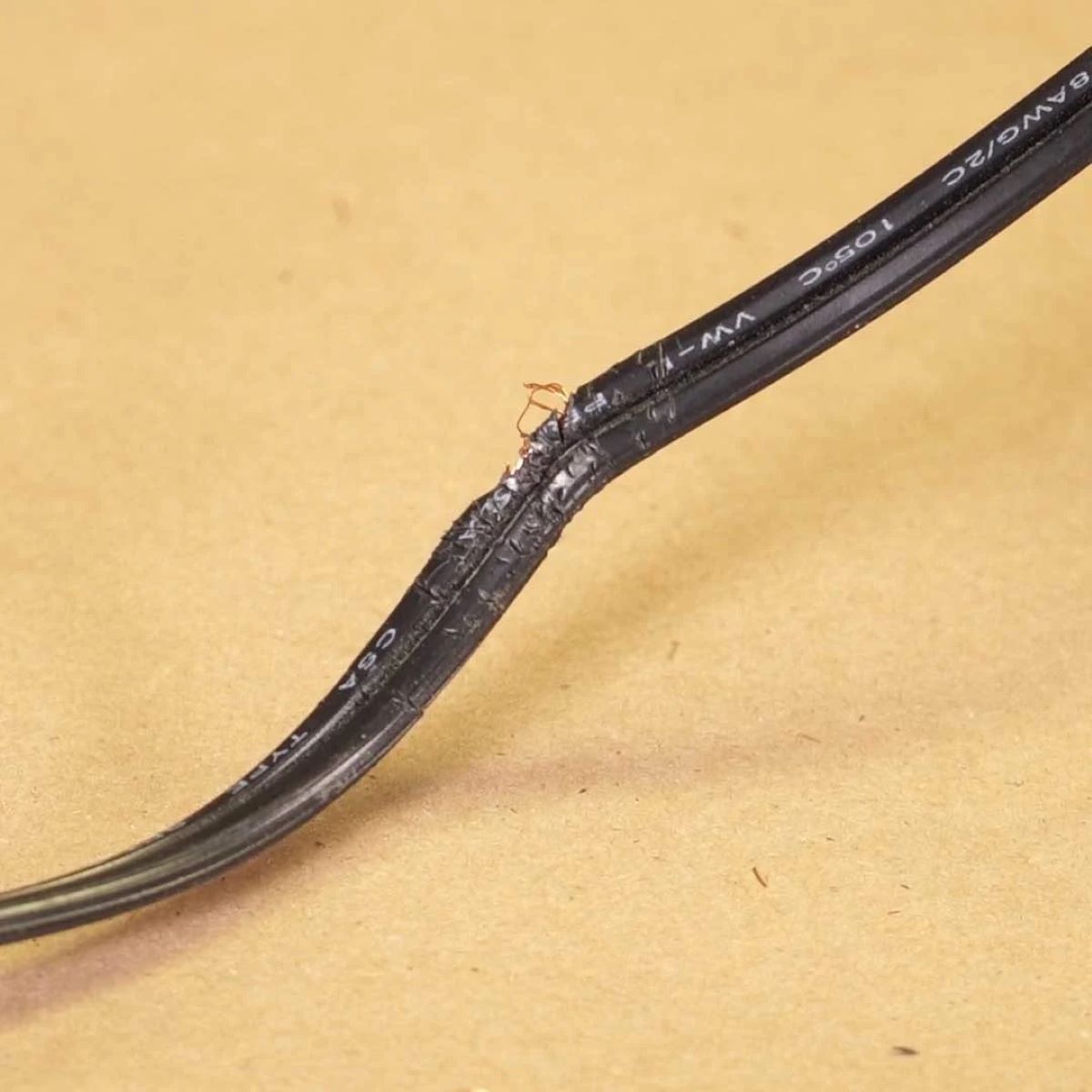

In addition to preventing accidents, protecting electrical cords also helps in preventing damage to the cords themselves. When left exposed to vehicles or heavy equipment, cords can be easily crushed, punctured, or severed, leading to electrical failures and costly downtime.

Another crucial aspect is protecting cords from exposure to moisture, dirt, and other environmental factors. Exposure to these elements can lead to electrical shorts, corrosion, and even electrical shocks, jeopardizing the safety of everyone involved. Protective covers provide a barrier against external elements, ensuring the longevity and safety of the cords.

Furthermore, protecting electrical cords over roadways helps in maintaining a professional and organized appearance. It showcases that your project prioritizes safety and adheres to industry standards. This can boost the confidence of workers, clients, and stakeholders, and can also positively impact the reputation of your business.

Lastly, protecting electrical cords over roadways can help in complying with safety regulations and standards set by regulatory bodies. Failure to comply with these regulations can not only result in fines and penalties but can also lead to work stoppages and potential legal actions.

Considering the numerous benefits and the potential risks involved, it is evident that protecting electrical cords over roadways should be a top priority for any project involving temporary power supply. By investing in appropriate protective measures, you can maintain a safe working environment, prevent accidents and damage to equipment, and ensure the successful completion of your project.

Potential Hazards of Leaving Electrical Cords Unprotected

Leaving electrical cords unprotected over roadways can have severe consequences and expose workers, pedestrians, and properties to various hazards. Understanding these potential risks is essential for recognizing the importance of implementing proper protective measures.

One of the primary hazards of leaving electrical cords unprotected is the risk of trips and falls. Unseen or poorly marked cords can become a serious tripping hazard, leading to injuries for workers, pedestrians, and even drivers. Trips and falls can result in broken bones, sprains, head injuries, and other serious consequences.

Furthermore, exposed cords are susceptible to damage from vehicles, machinery, or heavy equipment passing over them. These cords can be crushed, severed, or even pulled loose, resulting in electrical failures, power outages, and potentially catastrophic accidents. Not only can this disrupt operations and cause costly downtime, but it can also put workers at risk of electric shock or other electrical hazards.

Leaving electrical cords unprotected also increases the risk of electrical shorts, especially in wet or damp conditions. Moisture, dirt, and debris can easily enter the cord’s exposed ends, causing electrical failures, sparks, and potential fires. Such incidents can lead to property damage, injuries, and even loss of life.

Another significant hazard is the potential for unauthorized access or tampering with the exposed cords. Vandals or individuals with malicious intent may tamper with the cords, leading to power disruptions, equipment damage, or even deliberate electrocution. Protecting the cords helps deter such unauthorized access, ensuring the safety of the electrical supply and preventing intentional harm.

Exposure to environmental elements such as dust, sunlight, extreme temperatures, and chemicals can also adversely affect the integrity and performance of electrical cords. Over time, this exposure can cause degradation, insulation breakdown, and increased fire risks. Proper protection helps to mitigate these risks and extend the lifespan of the cords.

In summary, leaving electrical cords unprotected over roadways poses a range of hazards, including tripping accidents, damage to cords and equipment, electrical shorts and shocks, tampering risks, and environmental deterioration. By recognizing these potential risks, we can better appreciate the need for proactive measures to protect electrical cords and ensure the safety and efficiency of operations.

Types of Protective Measures for Electrical Cords

When it comes to protecting electrical cords over roadways, there are several effective measures that can be implemented to increase safety and minimize potential hazards. Let’s explore some of the commonly used protective measures:

- Cord Covers: Cord covers are a popular choice for protecting electrical cords. These covers are typically made of durable materials, such as rubber or polyurethane, which provide a protective barrier and help prevent trips and falls. Cord covers are available in various sizes and configurations to accommodate different cord diameters and lengths. They are also designed to withstand heavy foot traffic and vehicular loads.

- Cable Ramps: Cable ramps are specifically designed to protect cords and cables from vehicle traffic. These ramps feature channels or grooves that allow cords to pass through while providing a safe pathway for vehicles to drive over. Cable ramps are often made of heavy-duty rubber or polyurethane and are available in different load-bearing capacities to suit various applications.

- Cable Protectors: Cable protectors are similar to cord covers but are typically used in high-traffic areas or where cords need to be protected from heavy machinery or equipment. These protectors are made of sturdy materials and have a greater load-bearing capacity. They often feature multiple channels to separate and organize different cords, ensuring efficient cable management.

- Bridges and Trenches: In situations where cords need to be protected over long distances, such as construction sites or outdoor events, bridges and trenches are effective options. Bridges consist of elevated platforms that allow cords to pass over uneven surfaces or obstacles, while trenches provide a protected pathway by burying the cords underground.

- Warning Signs and Markings: Using clear signage and markings is an essential and cost-effective measure to alert individuals of the presence of electrical cords. These signs should be placed at appropriate intervals to indicate the cord’s location and potential hazards, ensuring that people are aware and can exercise caution when navigating the area.

It’s important to note that each protective measure has its own advantages and limitations. The choice of the appropriate measure depends on factors such as the level of foot and vehicle traffic, the durability required, the length of the cord, and the specific application. Consulting with safety professionals or industry experts can help in determining the most suitable protective measure for your specific needs.

When running electrical cords over a roadway, use cable protectors or ramps to prevent damage and tripping hazards. Make sure the cords are secured and clearly marked for visibility.

Choosing the Right Protective Cover for Electrical Cords

Choosing the right protective cover for electrical cords is crucial to ensure optimal safety and effectiveness in any project involving temporary power supply over roadways. Here are some key factors to consider when selecting a protective cover:

- Durability: The protective cover should be durable enough to withstand the specific environment and conditions it will be exposed to. It should be able to resist heavy foot traffic, vehicular loads, extreme weather, and potential damage from machinery or equipment.

- Load Capacity: Consider the weight-bearing capacity required for the protective cover. It should be able to support the weight of vehicles and equipment that may pass over it without causing damage to the cords or compromising safety.

- Size and Configuration: Ensure that the protective cover is appropriately sized and configured for the cords being used. It should accommodate the cord diameter and length adequately, allowing for a secure fit and protection along the entire length of the cord.

- Ease of Installation: Look for a protective cover that is easy to install and remove. Ideally, it should have a simple design that allows for quick setup, minimizing downtime and interruptions in operations.

- Visibility: The protective cover should be highly visible to ensure that individuals can easily identify the presence of cords and take precautionary measures. Bright colors or reflective strips can enhance visibility, especially in low-light conditions.

- Flexibility: Depending on the specific project requirements, consider if the protective cover needs to accommodate bends, corners, or uneven surfaces. Flexible covers can easily adapt to various terrains, ensuring a secure and effective protection solution.

- Maintenance: Evaluate the maintenance requirements of the protective cover. It should be easy to clean, resistant to chemicals and environmental elements, and capable of withstanding regular use without deteriorating or compromising its protective capabilities.

Additionally, it is recommended to consult with safety professionals or industry experts who can provide guidance based on your specific project requirements. They can help assess the risks involved and recommend the most suitable protective cover that meets safety standards and regulations.

Remember, investing in the right protective cover ensures the longevity of electrical cords, minimizes the risk of accidents or damage, and contributes to a safe and efficient working environment.

Read more: How To Cut An Electrical Cord

Proper Installation of Protective Covers for Electrical Cords

Proper installation of protective covers for electrical cords is essential to ensure effective protection and maintain a safe working environment. Follow these guidelines to ensure the correct installation process:

- Clean the Area: Before installing the protective cover, ensure the area is clean and free of debris. Remove any obstacles or objects that may interfere with the installation or pose a tripping hazard.

- Prepare the Cords: Straighten out the electrical cords and ensure they are free from knots or tangles. This will facilitate the smooth installation of the protective cover and prevent any damage to the cords.

- Position the Cover: Place the protective cover over the electrical cords, making sure that it fully encloses and aligns with the length of the cord. Ensure that the cover is centered and evenly distributed along the entire length of the cords.

- Secure the Cover: Depending on the type of protective cover, secure it in place using the provided fastening mechanisms. This may include hook-and-loop closures, interlocking tabs, or integrated connectors. Follow the manufacturer’s instructions to ensure a secure and tight fit.

- Smooth out Any Wrinkles or Bumps: After securing the cover, ensure that it lies flat and smooth, without any wrinkles or bumps. This will prevent tripping hazards and ensure a uniform surface for vehicles or equipment to pass over.

- Test the Installation: Once the protective cover is in place, conduct a comprehensive test to ensure its effectiveness. Walk over the cover to ensure it remains securely in position and does not shift or dislodge. If vehicles or heavy equipment will be passing over the cords, ensure that the cover can withstand the load without causing damage to the cords or compromising safety.

- Inspect Regularly: Regularly inspect the protective covers and the condition of the electrical cords. Look for any signs of wear, damage, or degradation. Replace or repair any protective covers that show signs of deterioration to ensure continued protection.

It is crucial to follow the manufacturer’s guidelines for installation and refer to any specific instructions or recommendations provided. Improper installation or failure to properly secure the protective cover can compromise its effectiveness and lead to potential hazards.

Remember, proper installation of protective covers is key in ensuring the safety and longevity of electrical cords and preventing accidents or damage to equipment.

Maintenance and Inspection of Protective Covers for Electrical Cords

Maintenance and regular inspection of protective covers for electrical cords are crucial to ensure their continued effectiveness and the safety of your work environment. Here are some key guidelines to follow:

- Regular Cleaning: Clean the protective covers regularly to remove any dirt, debris, or other contaminants that may accumulate on the surface. Using a mild detergent or cleaning solution, scrub the covers gently with a soft brush or cloth. Rinse with water and allow them to air dry before reinstalling.

- Inspect for Wear and Tear: Routinely inspect the protective covers for any signs of wear, tear, or damage. Look for cracks, frayed edges, or punctures that may compromise the integrity of the covers. If you notice any signs of damage, replace the covers immediately to maintain optimal protection.

- Check for Proper Fit: Ensure that the protective covers fit securely and snugly around the electrical cords. Over time, covers may shift or become loose, which can create tripping hazards or expose cords to potential damage. Adjust or re-secure the covers as necessary to maintain a tight and secure fit.

- Inspect Fastening Mechanisms: If the protective covers use fastening mechanisms such as hook-and-loop closures or interlocking tabs, inspect them regularly to ensure they are functioning properly. If the fasteners show signs of wear or no longer secure the covers tightly, consider replacing them or reinforcing them with suitable alternatives.

- Testing Load Capacity: If the protective covers are designed to withstand vehicle traffic or heavy equipment, periodically test their load capacity to ensure they can still bear the weight without causing damage to the cords or compromising safety. If any signs of deformation or failure are observed, replace the covers with ones that can handle the intended load.

- Consider Environmental Factors: Take into account the specific environment in which the protective covers are used. Elements such as exposure to sunlight, extreme temperatures, chemicals, or moisture can impact their durability and performance. Choose covers that are resistant to these factors or consider additional protective measures if necessary.

- Training and Education: Provide proper training and education to those who will be responsible for the maintenance and inspection of the protective covers. Teach them how to identify signs of wear, damage, or inadequate installation. Encourage reporting of any issues to address them promptly and maintain a safe working environment.

Regular maintenance and inspection of protective covers for electrical cords are essential to ensure their longevity and the continued protection they provide. By following these guidelines, you can detect and address any potential issues early on, minimizing risks and ensuring the safety and effectiveness of your temporary power supply over roadways.

Conclusion

Protecting electrical cords over roadways is vital for ensuring the safety of workers, pedestrians, and the successful execution of projects involving temporary power supply. By implementing proper protective measures, potential hazards such as trips, damage to cords, electrical shorts, tampering risks, and environmental degradation can be minimized or avoided.

Choosing the right protective cover for electrical cords is crucial. Consider factors such as durability, load capacity, size, ease of installation, visibility, flexibility, and maintenance requirements when selecting a suitable protective cover.

Proper installation of protective covers is essential to ensure their effectiveness. This involves cleaning the area, preparing the cords, correctly positioning and securing the cover, and conducting thorough testing to ensure stability and functionality.

Maintaining and inspecting protective covers on a regular basis is critical for their ongoing effectiveness. Cleaning the covers, checking for wear and tear, ensuring a proper fit, inspecting fastening mechanisms, testing load capacity, considering environmental factors, and providing training and education are all important aspects of maintaining the protective covers.

By prioritizing safety and implementing appropriate protective measures, you can create a secure working environment, prevent accidents and damage to equipment, and comply with safety regulations and standards.

Remember, protecting electrical cords over roadways is not just about compliance – it is about safeguarding the well-being of individuals and ensuring the smooth and successful completion of projects. By understanding the importance of protection, choosing the right protective cover, installing it correctly, and maintaining it regularly, you can create a safe and productive work environment for everyone involved.

Frequently Asked Questions about How To Protect Electrical Cord Over Roadway

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Protect Electrical Cord Over Roadway”