Articles

How To Splice Into Existing Electrical Wire

Modified: March 1, 2024

Looking for informative articles on how to properly splice into existing electrical wire? Find step-by-step guidance and expert tips to ensure a safe and successful electrical project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Splicing into existing electrical wire may be necessary in certain situations, such as when adding a new electrical outlet or extending a circuit. This process involves connecting new wires to an already existing electrical system to provide power to additional devices or fixtures. However, it is crucial to approach this task with caution and follow proper safety procedures to avoid the risk of electrical shock or fire hazards.

In this article, we will guide you through the process of safely splicing into existing electrical wire, providing essential tips and step-by-step instructions. Whether you are a DIY enthusiast or a professional electrician, this comprehensive guide will help you execute the task effectively and in compliance with electrical codes.

Before diving into the details of splicing into existing electrical wire, it is essential to understand the concept and purpose of this procedure. Splicing refers to joining two or more wires together to create a continuous electrical connection. When splicing into existing wire, it means adding new wires to an existing circuit without interrupting the flow of electricity.

Safety should always be the top priority when working with electrical systems. Before attempting any electrical tasks, ensure that you have a basic understanding of electrical concepts and always take necessary precautions. Make sure to switch off the power supply to the circuit you will be working on and use appropriate safety equipment such as insulated gloves and goggles.

Now that we have established the importance of safety, let’s move on to the tools and materials you will need for splicing into existing electrical wire. By being properly prepared, you can ensure a smooth and efficient process, reducing the risk of errors or accidents.

Next, we will discuss the step-by-step process of splicing into existing electrical wire. This guide will provide you with clear instructions to follow, starting from the preparation stage to the final testing and verification of the splice.

Remember, it is crucial to adhere to your local electrical codes and regulations when undertaking any electrical work. If you are unsure about any aspect of splicing into existing electrical wire, it is recommended to consult a licensed electrician for guidance.

Now that we have covered the introduction and set the foundation, let’s proceed to the next section, where we will outline the necessary safety precautions to take before starting the project.

Key Takeaways:

- Safety is paramount when splicing into existing electrical wire. Always turn off the power, use proper safety equipment, and adhere to electrical codes to minimize the risk of electrical shock and fire hazards.

- Thorough testing and verification of the splice are essential for ensuring its reliability. From checking connections to performing load tests, these steps help maintain the long-term safety and functionality of the electrical connection.

Read more: How To Splice Electrical Wire

What is Splicing into Existing Electrical Wire?

Splicing into existing electrical wire involves the process of connecting new wires to an already established electrical circuit. This technique is commonly used when additional outlets, fixtures, or devices need to be powered by an existing electrical system.

When you splice into existing electrical wire, you are essentially extending the circuit to accommodate the new electrical load. This allows you to branch off from the existing wiring and provide power to new locations without the need for a separate circuit.

Splicing into existing electrical wire is a skill that can be essential for various scenarios. It can be used to add outlets in a room, install additional lighting fixtures, or connect new appliances. By understanding how to safely and properly splice into existing wire, you can expand and enhance the functionality of your electrical system.

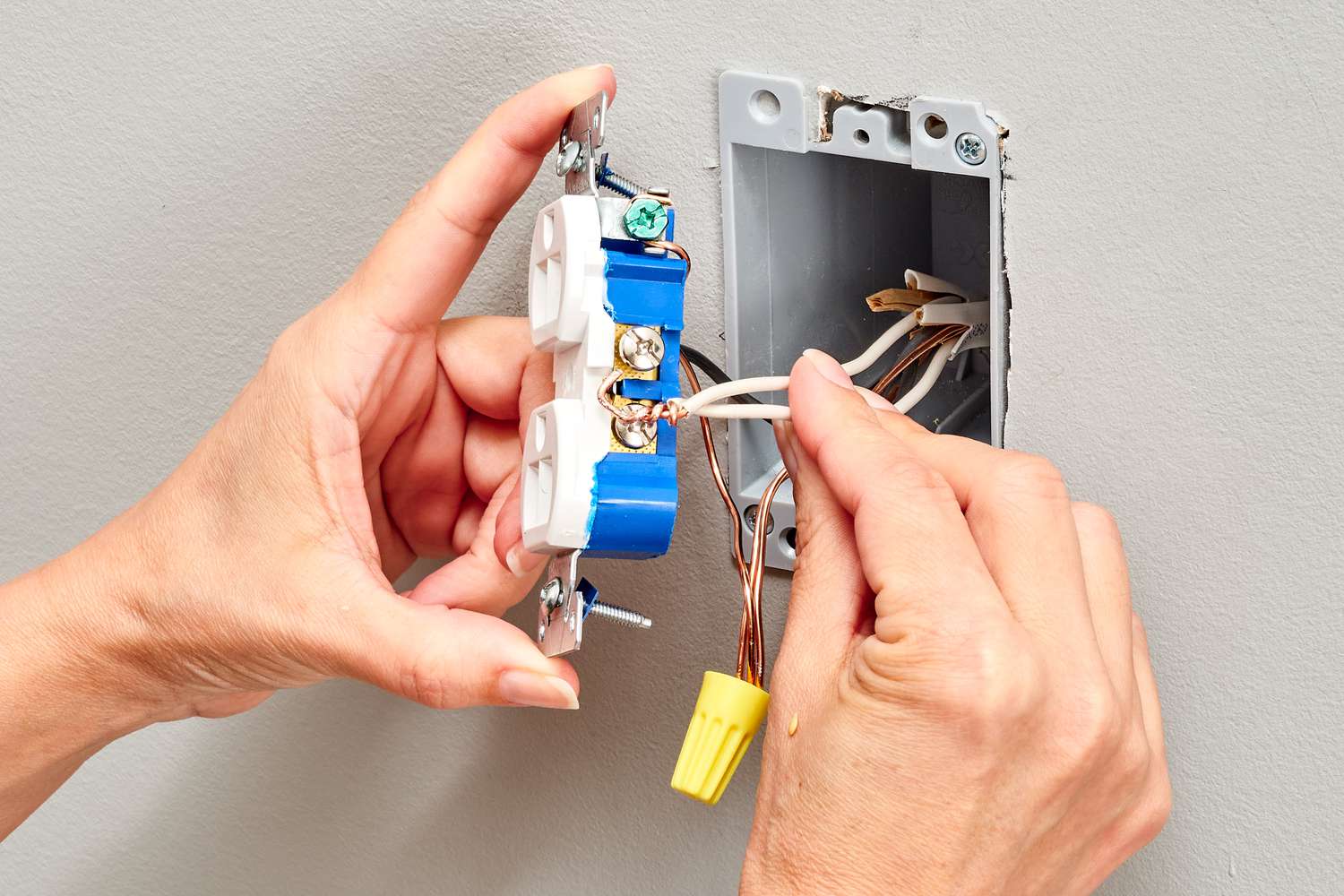

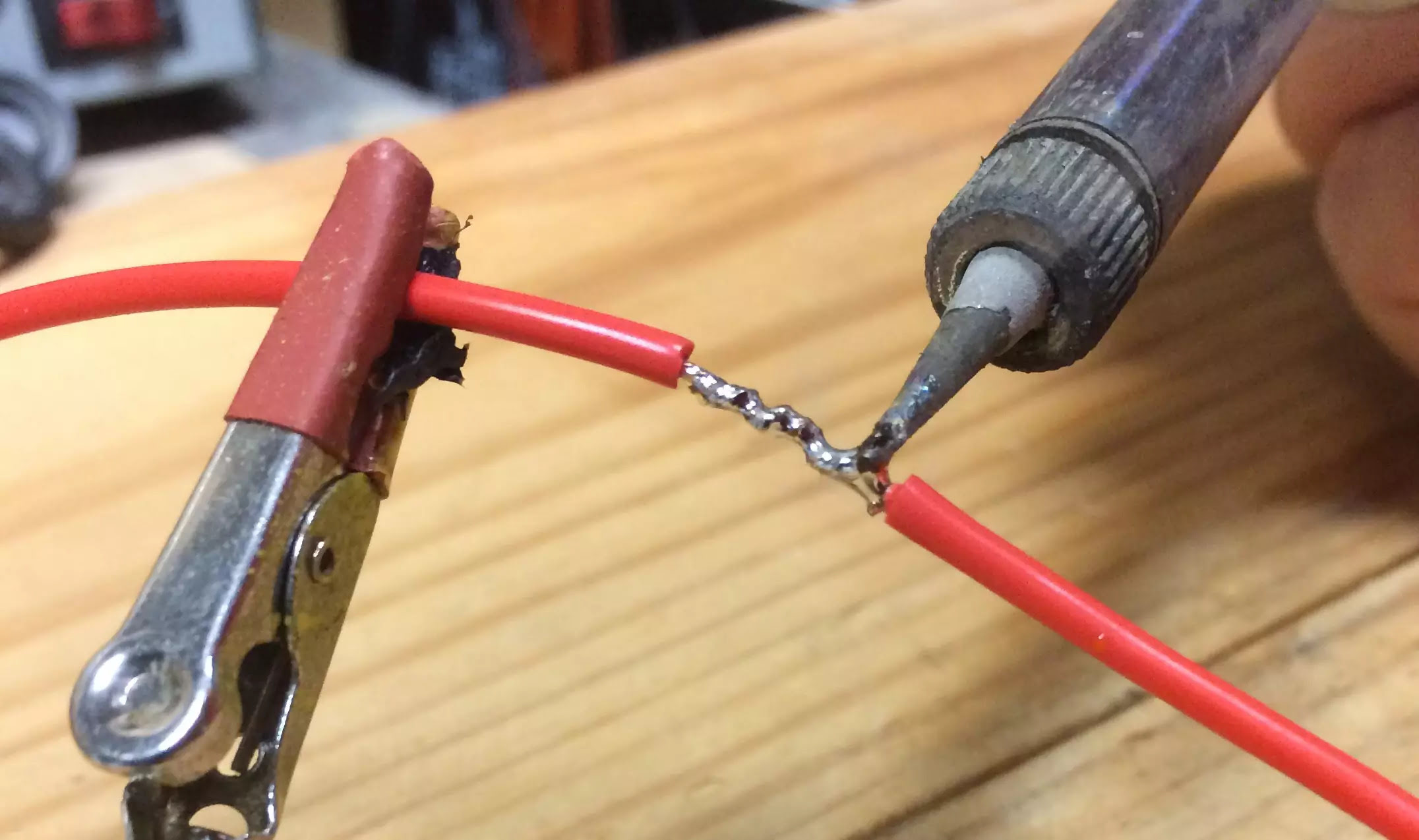

There are two primary methods of splicing into existing electrical wire: using wire connectors or soldering. Wire connectors, also known as wire nuts or twist-on connectors, are the more common and accessible method for homeowners and DIY enthusiasts. Soldering, on the other hand, involves heating and melting solder onto the wires to create a strong and permanent connection. Soldering is typically used in more specialized electrical work and is commonly employed by professional electricians.

Regardless of the method you choose, it is crucial to ensure that the splice is secure, insulated, and meets electrical code requirements. This ensures the safety and reliability of the electrical connection, preventing any potential hazards such as short circuits, overheating, or electrical shocks.

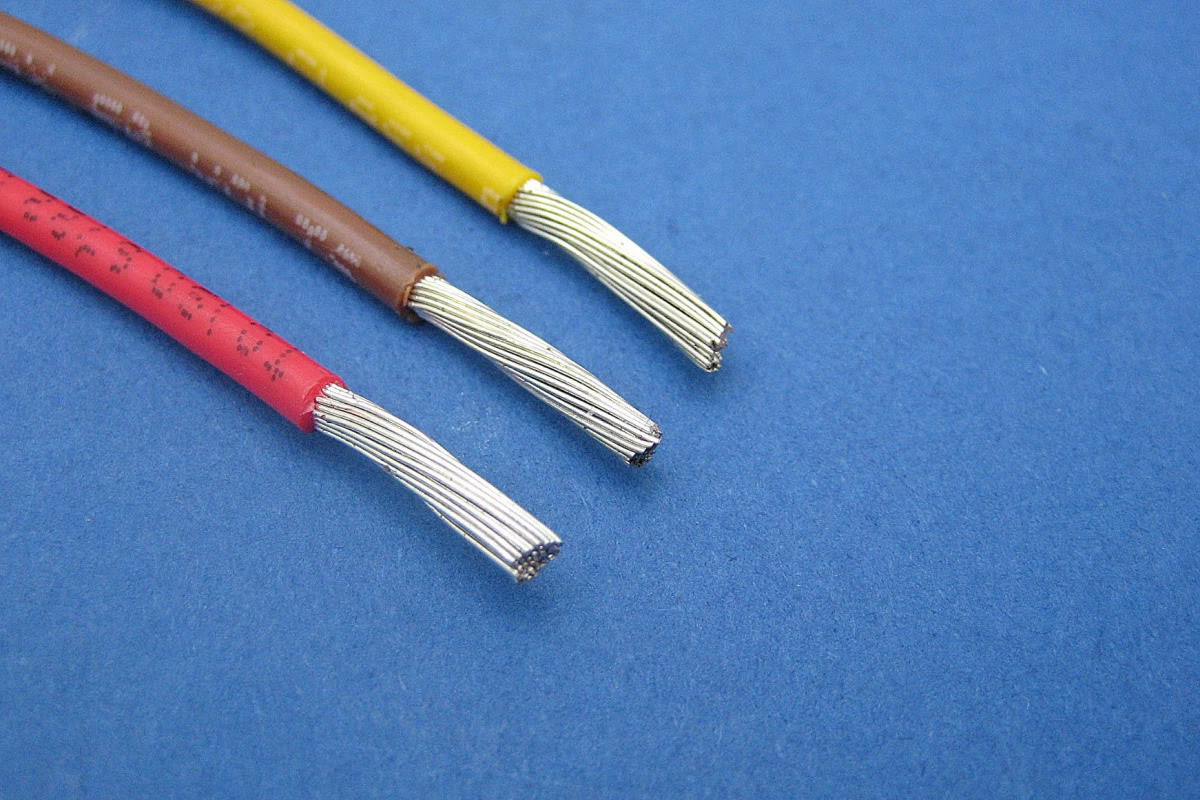

Splicing into existing electrical wire requires a thorough understanding of electrical systems and wiring principles. It is important to identify the type of wire being used, such as copper or aluminum, and determine the appropriate wire size and gauge. Additionally, you need to consider factors such as the maximum load of the circuit, the length of wire required, and the specific electrical codes and regulations in your area.

When splicing into existing wire, it is crucial to plan the project carefully and adhere to safety guidelines. This includes switching off the power to the circuit you will be working on, using appropriate safety equipment, and following proper procedures to prevent any accidents or damage to the electrical system.

Now that we have provided an overview of what splicing into existing electrical wire entails, let’s move on to the next section, where we will discuss the essential safety precautions that need to be followed before starting the splicing process.

Safety Precautions

Splicing into existing electrical wire requires working with live electrical circuits, which can be dangerous if proper safety precautions are not followed. To ensure a safe working environment and minimize the risk of electrical shock or fire hazards, it is essential to adhere to the following safety precautions:

1. Turn off the Power: Before attempting any splicing into existing electrical wire, always switch off the power supply to the circuit you will be working on. This can be done by turning off the corresponding circuit breaker in the electrical panel. Double-check with a voltage tester to confirm that there is no electricity flowing through the wires.

2. Use Proper Safety Equipment: Wear appropriate safety gear, including insulated gloves, safety goggles, and protective clothing. Insulated gloves provide protection against electrical shock, while safety goggles shield the eyes from any debris or sparks that may occur during the process.

3. Properly Insulate the Work Area: Clear the work area of any flammable materials, and ensure it is well-lit and ventilated. Keep a fire extinguisher nearby in case of emergency. Avoid working near water sources, as water and electricity can be a lethal combination.

4. Identify and Label Wires: Before making any connections, ensure that all wires are properly identified and labeled. This will help prevent confusion and ensure accurate matching during the splicing process.

5. Select the Correct Wire Connectors: Choose the appropriate wire connectors for your specific application. Ensure that the connectors are rated for the wire size and gauge you are using. Using the wrong connectors can lead to loose connections, which can cause overheating and potential fire hazards.

6. Strip and Trim Wires Properly: Use wire strippers to remove the insulation from the ends of the wires. Be careful not to damage or nick the wire strands while stripping. Trim any excess wire length to ensure a neat and secure connection.

7. Avoid Overloading the Circuit: Determine the load capacity of the circuit you are splicing into and ensure that you do not exceed it. Overloading a circuit can cause power fluctuations, overheating, and potential electrical hazards. If in doubt, consult a licensed electrician for assistance.

8. Follow Electrical Codes and Regulations: Familiarize yourself with the electrical codes and regulations specific to your location. These codes outline the proper methods and guidelines for electrical work to ensure safety and compliance. Adhere to these regulations to prevent any violations and potential hazards.

9. Test and Verify the Splice: Once the splicing is complete, carefully test and verify the connection using a voltage tester or a multimeter. This will ensure that the splice is secure and does not pose any safety risks.

10. Consult a Professional if Needed: If you are uncertain about any aspect of splicing into existing electrical wire, it is always advisable to consult a licensed electrician. They have the expertise and experience to address any concerns and ensure the job is done safely and correctly.

By following these safety precautions, you can mitigate the risks associated with splicing into existing electrical wire and create a safe working environment. Remember, ensuring safety should always be your top priority when working with electricity.

Now that we have covered the essential safety precautions, let’s proceed to the next section where we will outline the tools and materials required for splicing into existing electrical wire.

Tools and Materials Required

Before attempting to splice into existing electrical wire, it is important to gather all the necessary tools and materials. Having the right equipment on hand will ensure a smooth and efficient splicing process. Here is a list of the tools and materials you will need:

1. Wire Strippers: These specialized pliers are used to remove the insulation from the ends of the wires. Look for a wire stripper with multiple notches to accommodate different wire sizes.

2. Wire Connectors (Wire Nuts): Wire connectors, also known as wire nuts, are essential for creating secure and insulated connections. Choose wire nuts that are appropriate for the wire size and gauge you are working with. It is recommended to have a variety of sizes on hand for different wire combinations.

3. Voltage Tester: A voltage tester is used to verify if there is electricity flowing through the wires. This tool ensures that the power has been switched off before working on the circuit. Choose a quality voltage tester that can accurately detect the presence or absence of electrical current.

4. Insulated Gloves: Insulated gloves provide protection against electric shock. They act as a barrier between your hands and any live wires. Ensure that the gloves have proper insulation ratings and fit well for maximum safety.

5. Safety Goggles: Safety goggles protect your eyes from any debris or sparks that may occur during the splicing process. Choose goggles that provide a comfortable fit and have the appropriate safety ratings.

6. Screwdrivers: A set of screwdrivers, including both flathead and Phillips head, will come in handy for removing and securing electrical outlet covers, as well as connecting wires to terminals.

7. Wire Cutters: Wire cutters are used to trim excess wire length and ensure clean and precise cuts. Look for wire cutters with sharp blades and comfortable handles for ease of use.

8. Electrical Tape: Electrical tape is used to insulate and secure the wire connections. It provides an added layer of protection against exposed wires and aids in preventing accidental contact.

9. Wire Labels: Labeling the wires is essential for identifying and organizing the connections. Use adhesive-backed labels or marker tags to clearly mark each wire for ease of identification during the splicing process.

10. Wire Fish Tape or Electrical Snake: A wire fish tape or electrical snake is useful for guiding and pulling the new wires through walls, conduits, or hard-to-reach areas. This tool helps facilitate the routing of wires to their desired location.

11. Wire Strain Relief: Wire strain relief helps prevent unnecessary stress or tension on the wires. It is particularly important when splicing into existing wire in areas where there may be frequent movement or vibration.

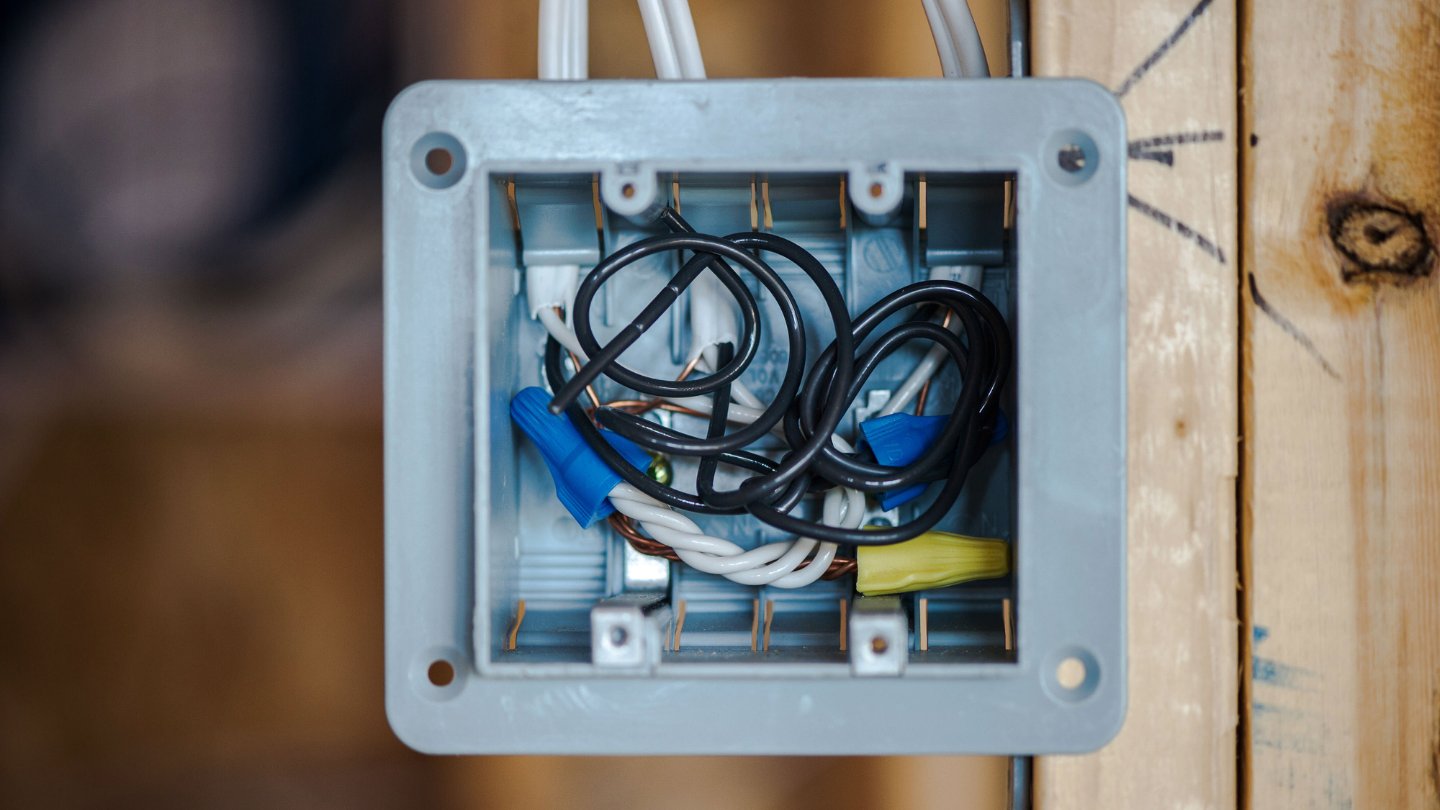

12. Electrical Box: An electrical box is required when adding new outlets or connecting wires to fixtures. The electrical box ensures that the connections are enclosed and protected.

13. Wire Nuts or Connectors Box: It is advisable to have a variety of wire nuts and connectors on hand to accommodate different wire combinations and sizes.

By ensuring that you have all the necessary tools and materials listed above, you will be well-prepared to complete the splicing into existing electrical wire. Always prioritize safety and proper equipment when working with electricity.

Now that we have covered the tools and materials required, let’s move on to the step-by-step guide of splicing into existing electrical wire.

When splicing into existing electrical wire, always turn off the power at the breaker before starting. Use wire strippers to carefully expose a small section of the existing wire, and then connect the new wire using wire connectors. Always double-check your work and test the connection before restoring power.

Step-by-Step Guide to Splicing into Existing Electrical Wire

Splicing into existing electrical wire requires careful attention to detail and adherence to safety protocols. Follow this step-by-step guide to ensure a smooth and successful splicing process:

1. Turn off the Power: Begin by switching off the power supply to the circuit you will be working on. Locate the circuit breaker in the electrical panel and flip it to the off position. Use a voltage tester to confirm that there is no electricity flowing through the wires.

2. Prepare the Work Area: Clear the area where you will be working and ensure it is well-lit and ventilated. Remove any debris or obstacles that could interfere with your task.

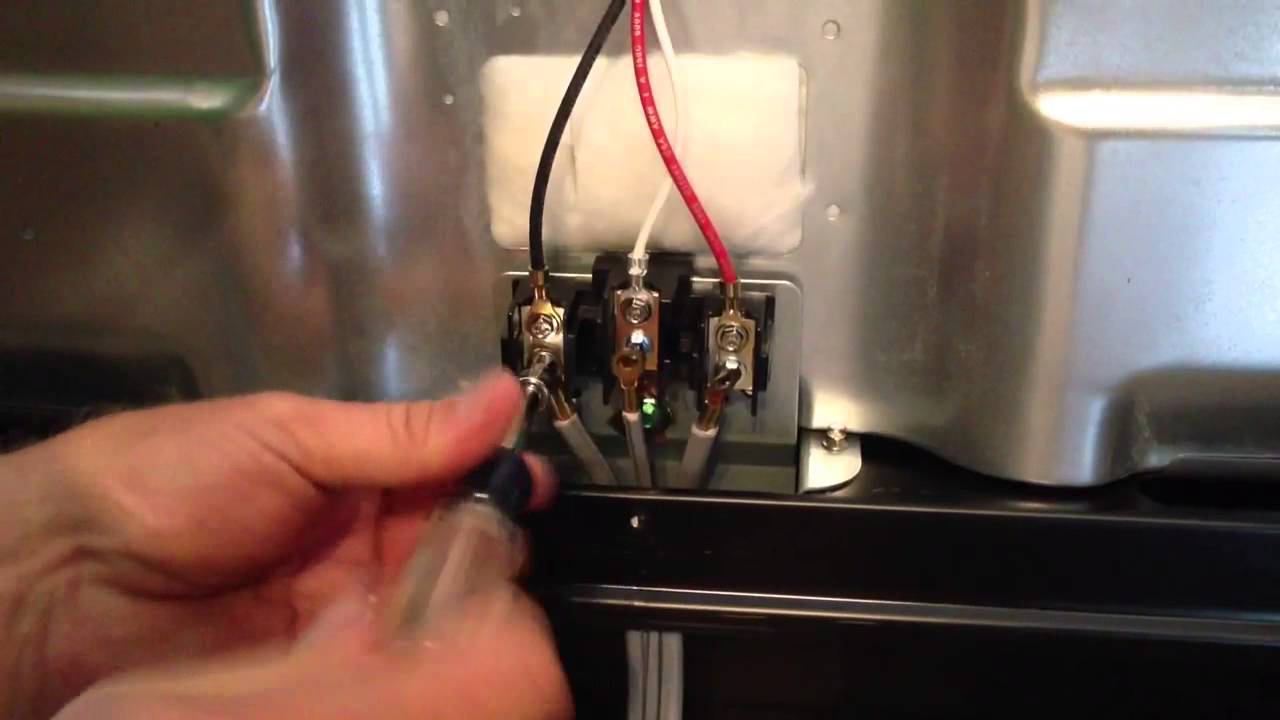

3. Identify the Wires: Carefully identify the wires you will be splicing into. It is essential to understand which wires are live, neutral, and ground. Typically, live wires are black or red, neutral wires are white, and ground wires are green or bare copper.

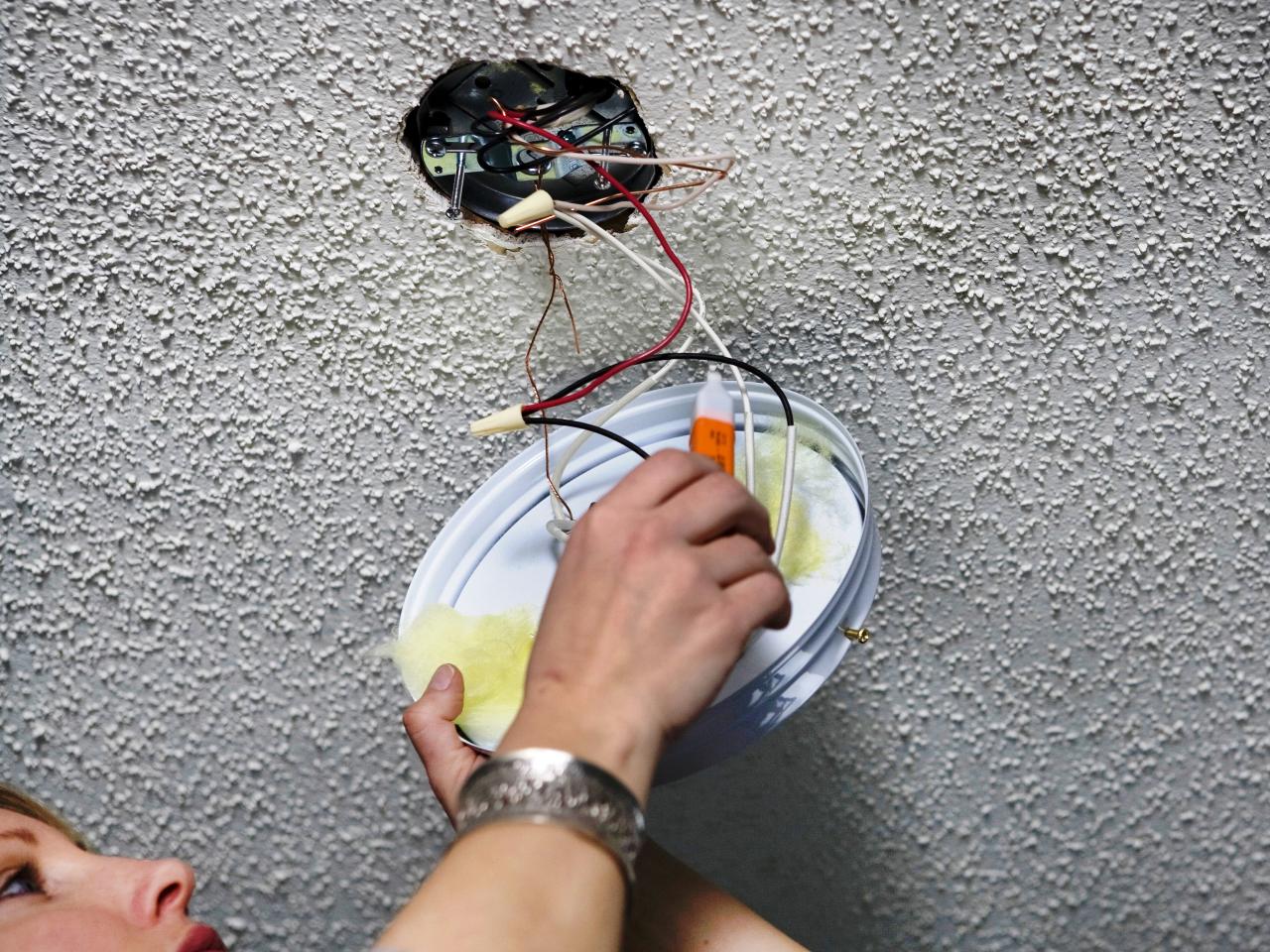

4. Strip the Wire Insulation: Use wire strippers to remove approximately 3/4 inch of insulation from the ends of the wires that will be spliced. Twist the exposed wire strands together to create a secure connection.

5. Select the Correct Wire Connector: Choose a wire nut or connector that is appropriate for the wire size and gauge you are working with. Place the wire connector over the twisted wire ends and twist it clockwise until it is tightly secured.

6. Insulate the Wire Connection: Wrap electrical tape around the wire nut or connector to provide an additional layer of insulation and secure the connection. Ensure that the electrical tape covers the wire nut completely.

7. Extend the Circuit: If you are extending the circuit to a new location, use wire fish tape or electrical snake to guide and pull the new wires through walls, conduits, or other pathways. Ensure that the new wires are properly secured and protected along the entire route.

8. Make the Connection: Once the new wires reach their destination, strip the insulation from the ends of the new wires and the existing wires. Connect them together using the same techniques as earlier, utilizing appropriate wire connectors and insulation methods.

9. Secure the Connections: After making all the necessary connections, ensure that they are secure and tightly fastened. Check for any loose wires or connectors and make any adjustments as needed.

10. Test the Splice: Before restoring power, double-check all the wire connections and ensure they are properly insulated and secure. Use a voltage tester to verify that there is no electricity flowing through the wires.

11. Restore Power: Once you are confident that the splice is successful and the connections are safe, you can restore power to the circuit by flipping the circuit breaker back to the on position.

12. Testing and Verifying the Splice: After restoring power, test the newly spliced wires to ensure they are working correctly. Connect a light fixture or outlet to the circuit and check that it is operating as expected.

Remember, it is crucial to consult the electrical codes and regulations specific to your area throughout the entire splicing process. If you are unsure about any aspect of the procedure or encounter any difficulties, it is advisable to seek the assistance of a licensed electrician.

Congratulations! You have successfully spliced into existing electrical wire. By following this step-by-step guide and exercising caution, you have expanded the capabilities of your electrical system and added new functionality.

In the next section, we will discuss testing and verifying the splice to ensure its reliability and safety.

Testing and Verifying the Splice

Testing and verifying the splice is a crucial step to ensure the safety and reliability of your electrical connection. By performing thorough checks and testing procedures, you can identify any potential issues or faults and address them before fully relying on the spliced wires. Follow these steps to test and verify the splice:

1. Double-Check the Connections: Before conducting any tests, visually inspect all connections to ensure they are securely tightened and properly insulated. Check that all wire nuts or connectors are firmly in place and that there are no loose or exposed wires.

2. Test for Continuity: Using a multimeter set to the continuity or resistance mode, test the continuity between the wires that have been spliced together. Touch one probe of the multimeter to one end of the splice and the other probe to the opposite end. A continuous reading indicates a properly functioning splice.

3. Inspect for Voltage: If you are connecting new devices or fixtures to the splice, use a voltage tester to confirm the presence of voltage at the newly added locations. Ensure that the voltages match the expected readings for the circuit you are working on.

4. Perform a Load Test: If possible, connect the devices or fixtures that will be powered by the splice and test that they are functioning correctly. This allows you to verify that the splice can handle the expected electrical load without any issues. Monitor for any unusual behavior, such as flickering lights or malfunctioning equipment.

5. Monitor for Heat: After the splice has been in operation for a period of time, check for any signs of excessive heat. Feel the wires near the splice and electrical connections to ensure they are not becoming abnormally hot. Excessive heat may indicate a loose connection or overloaded circuit.

6. Regular Maintenance: It is important to periodically inspect and maintain the spliced wires to ensure their ongoing reliability. Check for any signs of wear or damage, such as frayed insulation or loose connections. Make any necessary repairs or replacements promptly to prevent further issues.

By thoroughly testing and verifying the splice, you can identify and address any potential problems before they escalate into more significant electrical issues. This step helps ensure the long-term safety and functionality of your electrical system.

If at any point during the testing and verification process you find any abnormalities or are unsure about the results, it is advisable to consult a licensed electrician for further guidance and assistance. They have the expertise and knowledge to diagnose and resolve any electrical concerns effectively.

Now that you have successfully tested and verified the splice, you can have confidence in the reliability of your electrical connection. In the final section of this article, we will conclude with a summary and some key takeaways.

Conclusion

Splicing into existing electrical wire can be a necessary task when expanding or modifying an electrical system. By following the proper procedures and safety precautions outlined in this article, you can successfully and safely accomplish this task.

Throughout the process, it is crucial to prioritize safety. Always remember to switch off the power before working on the circuit, use the appropriate safety equipment, and adhere to electrical codes and regulations. Taking these precautions minimizes the risks of electrical shock and potential fire hazards.

Having the right tools and materials is essential for a smooth splicing process. Make sure you have wire strippers, wire nuts or connectors, voltage testers, insulated gloves, safety goggles, and other necessary equipment before starting the task. By being well-prepared, you can ensure a seamless splicing experience.

Following the step-by-step guide provided in this article, you can confidently splice into existing electrical wire. From turning off the power to testing and verifying the splice, each step contributes to a safe and reliable electrical connection.

Lastly, testing and verifying the splice are crucial steps to ensure its functionality and safety. By checking the connections, testing for continuity and voltage, and performing load tests, you can ensure the reliability of the splice. Regular maintenance and monitoring for any signs of issues will help maintain the long-term integrity of the spliced wires.

Remember, if you are uncertain about any aspect of splicing into existing electrical wire or encounter any difficulties during the process, it is always wise to consult with a licensed electrician. They have the expertise and knowledge to address any concerns and ensure the job is done correctly.

By mastering the art of splicing into existing electrical wire, you can expand the capabilities of your electrical system, add new devices or fixtures, and enhance the functionality of your space. Just remember to prioritize safety, adhere to electrical codes, and follow the step-by-step guide provided in this article.

Congratulations on acquiring the skills to safely and effectively splice into existing electrical wire. With this knowledge, you can confidently tackle electrical projects and make improvements to your electrical system.

Frequently Asked Questions about How To Splice Into Existing Electrical Wire

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Splice Into Existing Electrical Wire”