Articles

What Electrical Wire To Run Underground

Modified: October 28, 2024

Looking for articles on what electrical wire to run underground? Find the answers and expert advice you need to make the right decision.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to running electrical wire underground, there are several factors to consider. Whether you’re installing a new electrical system for a building or carrying out an outdoor project that requires electricity, it’s important to choose the right type of wire and follow the necessary safety precautions. This article will guide you through the process of selecting the appropriate electrical wire for underground installation and provide you with essential tips for a successful and safe installation.

Before you start any underground electrical wiring project, there are a few factors you need to take into consideration. The first and most important factor is compliance with local building codes and regulations. It’s crucial to familiarize yourself with the specific requirements in your area to ensure that you’re following proper guidelines.

Another important factor is the purpose of the underground wiring. Are you installing outdoor lighting, a new electrical circuit for a shed, or running power to an underground pool? Each of these scenarios may require different types of wire, so it’s essential to determine your specific needs before making a purchase.

The location of the underground wiring is also a significant factor. Will the wire be buried directly in the ground or placed inside a conduit? Different types of wire and wiring methods are suitable for these different scenarios, so it’s vital to assess the situation and choose the appropriate approach.

Lastly, it’s important to consider the environmental conditions that the wire will be exposed to. Is the area prone to moisture, extreme temperatures, or chemical exposure? These factors can impact the durability and lifespan of the wire, so selecting a wire that is specifically designed for those conditions is essential.

In the next sections, we will explore the different types of electrical wire suitable for underground installation, as well as the advantages and disadvantages of running electrical wire underground. We will also provide step-by-step instructions on how to safely install electrical wire underground. By the end of this article, you will have a comprehensive understanding of the best practices and considerations when running electrical wire underground.

Key Takeaways:

- Selecting the right type of wire and conduit, understanding local building codes, and following proper installation techniques are crucial for a successful and safe underground electrical wiring project.

- Underground electrical wiring offers benefits such as enhanced safety, improved aesthetics, and increased durability, but it requires careful planning, adherence to safety guidelines, and compliance with local building codes.

Read more: How To Run Electrical Conduit Underground

Factors to Consider Before Running Electrical Wire Underground

Before embarking on any underground electrical wire installation project, it’s crucial to carefully consider several factors. These factors will impact the type of wire, wiring method, and safety measures needed to ensure a successful installation. Here are the key factors to keep in mind:

- Local Building Codes: Start by familiarizing yourself with the local building codes and regulations regarding underground wiring. These codes provide specific guidelines on wire types, depth of burial, conduit requirements, and other safety measures. Compliance with these codes is essential for a safe and legal installation.

- Purpose of the Wiring: Determine the purpose of the underground wiring. Are you installing outdoor lighting, powering a detached garage, or adding electrical outlets to a patio? The specific purpose will dictate the gauge and type of wire needed. For example, heavier loads may require thicker gauge wire.

- Depth of Burial: Consider the proper depth at which the wire should be buried. The depth may vary depending on the local building codes and the type of wire being used. Typically, a depth of 18-24 inches is common for residential installations, but it’s important to consult the specific guidelines for your area.

- Environmental Factors: Assess the environmental conditions that the underground wiring will be exposed to. If the area is prone to moisture, for example, you may need to use wire rated for wet locations. Similarly, extreme temperatures, soil acidity, and exposure to chemicals can all impact the choice of wire and the necessary safety precautions.

- Load Calculation: Determine the expected electrical load that the wiring will need to support. This involves calculating the total wattage of all the devices and appliances that will be connected to the circuit. Proper load calculation ensures that the wire selected can handle the anticipated electrical demand without overheating or causing a voltage drop.

- Future Expansion: Consider any future expansion plans that may require additional electrical circuits. It’s advisable to install conduits or use wiring methods that allow for easy future additions. This foresight can save time and effort in the long run by avoiding the need for excavation and disruption to existing landscaping.

- Budget: Finally, consider your budget for the project. Different types of wire and wiring methods vary in cost, so it’s essential to strike a balance between quality and affordability. While it’s important not to compromise on safety, it’s also wise to find cost-effective solutions that meet your needs.

By thoroughly considering these factors, you can make informed decisions about the type of wire, wiring method, and safety measures needed for your underground electrical wire installation. Taking the time to plan and prepare will result in a safe, efficient, and long-lasting electrical system.

Types of Electrical Wire Suitable for Underground Installation

When it comes to underground electrical wiring, there are several types of wires available, each with its own characteristics and suitable applications. Let’s explore some of the common types of electrical wire that are suitable for underground installation:

- PVC-Coated Electrical Wire: PVC (Polyvinyl Chloride) coated electrical wire is one of the most commonly used wires for underground installations. It is designed to be highly resistant to moisture, chemicals, and abrasion, making it ideal for outdoor use. The PVC coating provides an extra layer of protection and helps to prolong the lifespan of the wire. PVC-coated wire is available in different gauges to accommodate various electrical loads.

- UF-B Electrical Wire: UF-B (Underground Feeder) wire is specifically designed for direct burial applications. It is often used for outdoor lighting, underground circuits, and other outdoor electrical projects. UF-B wire features solid insulation, which provides protection against moisture and can withstand exposure to sunlight. This type of wire is also resistant to temperature fluctuations, making it suitable for various climates.

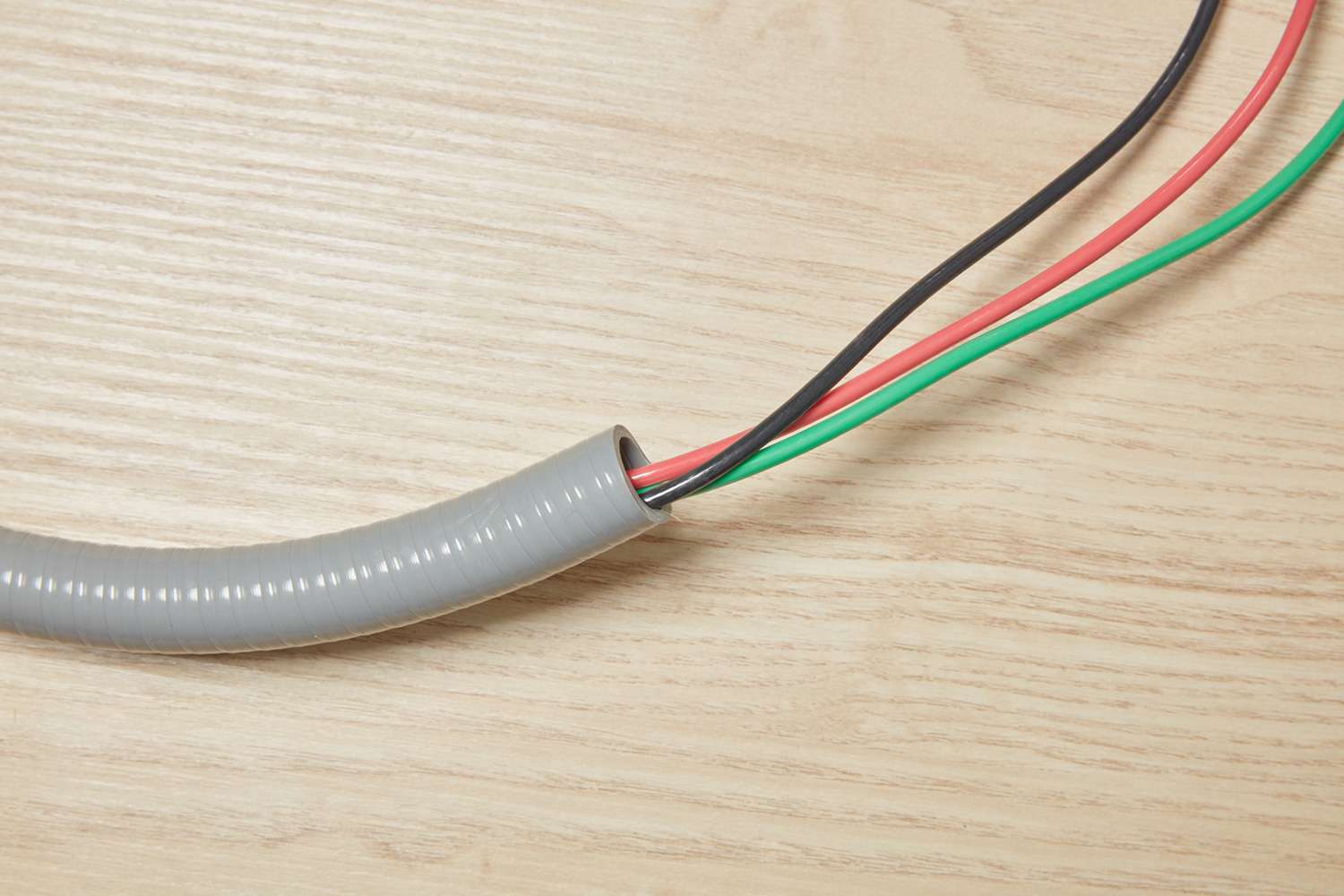

- THWN-2 Electrical Wire: THWN-2 (Thermoplastic Heat and Water-resistant Nylon-coated) wire is another popular choice for underground applications. It is designed to withstand high temperatures and is resistant to both moisture and sunlight. THWN-2 wire is often used in wet locations or areas where exposure to the elements is a concern. It can be installed directly in the ground or inside conduit.

- Direct Burial Electrical Wire: As the name suggests, direct burial electrical wire is specifically designed to be buried directly in the ground without the need for conduit. This type of wire typically has a rugged outer jacket that provides resistance to moisture, chemicals, and physical damage. Direct burial wire is often used for outdoor lighting, sprinkler systems, and landscape installations.

It is important to note that the type of wire you choose will depend on the specific requirements of your project, including the expected electrical load, environmental conditions, and local building codes. Consulting with a licensed electrician or knowledgeable professional can help you determine the most appropriate type of wire for your underground installation needs.

Regardless of the type of wire you select, it is essential to follow proper installation techniques and safety guidelines to ensure a successful and long-lasting underground electrical system. Proper wire sizing, correct burial depth, and adequate grounding are all crucial aspects to consider during the installation process.

By choosing the right type of wire and following the recommended installation practices, you can ensure a reliable and safe electrical system for your underground applications.

PVC-Coated Electrical Wire

PVC (Polyvinyl Chloride)-coated electrical wire is a commonly used and highly versatile option for underground installations. It is designed to withstand the harsh conditions of outdoor environments and provides excellent protection against moisture, chemicals, and physical damage. Let’s take a closer look at the features and benefits of PVC-coated electrical wire:

Resistance to Moisture: One of the key advantages of PVC-coated electrical wire is its resistance to moisture. The PVC coating acts as a barrier, preventing water from penetrating the wire and causing damage to the electrical system. This makes PVC-coated wire an ideal choice for underground installations where exposure to moisture is a concern, such as in garden lighting, underground sprinkler systems, or outdoor electrical circuits.

Chemical Resistance: PVC-coated wire is also resistant to a wide range of chemicals, making it suitable for installations where exposure to corrosive substances may occur. This resistance ensures that the wire remains protected and maintains its integrity, even in challenging environments.

Abrasion Resistance: The PVC coating provides an additional layer of protection, making the wire highly resistant to abrasion. This is particularly important during installation, as the wire may come into contact with rocks, sharp objects, or rough surfaces. The abrasion resistance of PVC-coated wire helps to prevent damage to the wire insulation, preserving the safety and functionality of the electrical system.

Durability: PVC-coated electrical wire is known for its durability and longevity. The PVC coating helps to extend the lifespan of the wire, even when exposed to external elements over an extended period. This durability ensures a reliable and long-lasting electrical system, reducing the need for frequent repairs or replacements.

Flexibility: PVC-coated wire is flexible and easy to work with, allowing for straightforward installation. Its flexibility enables the wire to navigate bends and corners without compromising its performance. This flexibility is especially beneficial when installing underground wiring, where maneuverability is often required to navigate through tight spaces or around landscaping features.

Wide Range of Gauges and Sizes: PVC-coated wire is available in a variety of gauges and sizes, allowing for customization based on the specific electrical load requirements of the installation. From low-voltage applications to high-powered systems, there is a PVC-coated wire suitable for various projects.

It’s important to note that PVC-coated wire should be installed in accordance with local building codes and regulations, ensuring proper burial depth and the use of appropriate connectors and junction boxes. Consulting with a licensed electrician or professional experienced in underground electrical installations is advisable to ensure compliance with electrical standards and safety protocols.

Overall, PVC-coated electrical wire is a reliable and versatile option for underground installations. Its resistance to moisture, chemicals, and abrasion, coupled with its durability and flexibility, makes it a popular choice for a wide range of applications. By selecting quality PVC-coated wire and following proper installation practices, you can create a robust and safe electrical system for your underground projects.

UF-B Electrical Wire

UF-B (Underground Feeder) electrical wire is a specially designed type of wire that is suitable for direct burial applications. It is commonly used for outdoor electrical installations and is built to withstand the challenges of underground environments. Let’s explore the features and benefits of UF-B electrical wire:

Durable Insulation: UF-B wire is constructed with a durable and moisture-resistant insulation material. This insulation protects the wire from water, soil, and other underground elements, ensuring the safe and reliable operation of your electrical system. The insulation also provides resistance against sunlight and can withstand exposure to harsh outdoor conditions without deteriorating over time.

Direct Burial Capability: UF-B wire is specifically designed to be buried directly underground without the need for conduit. This makes installation easier and more cost-effective compared to using conduit systems. The ability to directly bury the wire simplifies the process and reduces the possibility of moisture seeping into the wire, ensuring long-term performance and safety.

Versatility in Outdoor Applications: UF-B wire is widely used for various outdoor electrical applications. It can be used for lighting circuits, outdoor outlets, irrigation systems, and other outdoor electrical needs. Its versatility makes it an excellent choice for projects where direct burial is required.

Temperature and UV Resistance: UF-B wire is specifically engineered to withstand temperature fluctuations and prolonged exposure to sunlight. This allows it to maintain its integrity and electrical conductivity even in extreme weather conditions, ensuring the safety and longevity of your electrical system.

Multiple Conductor Sizes: UF-B wire is available in a range of conductor sizes to accommodate different electrical loads. This allows you to choose the appropriate gauge to handle the specific power requirements of your underground installation. It is essential to select the correct wire size to prevent overheating and ensure efficient power distribution.

Compliance with Building Codes: UF-B wire is designed to comply with the specific requirements outlined by local building codes and regulations for underground installations. Following these codes ensures that your installation is safe, legal, and meets the necessary standards for electrical wiring.

When working with UF-B wire, it is important to take proper safety precautions. Before installation, always ensure that the power is turned off to the area where the wire will be installed. Following proper electrical wiring techniques, such as securing connections with appropriate wire connectors and using junction boxes, is crucial for a safe and reliable installation. It is also recommended to seek the guidance of a licensed electrician to ensure compliance with local regulations.

Overall, UF-B electrical wire is a durable and dependable option for direct burial applications. Its ability to withstand moisture, temperature fluctuations, and UV exposure makes it an ideal choice for outdoor electrical installations. By selecting UF-B wire and following recommended installation practices, you can create a safe and efficient underground electrical system for a variety of outdoor projects.

Read more: How To Repair Underground Electrical Wire

THWN-2 Electrical Wire

THWN-2 (Thermoplastic Heat and Water-resistant Nylon-coated) electrical wire is a versatile and widely used option for underground electrical installations. It is specifically designed to withstand high temperatures and provide resistance against moisture and other environmental factors. Let’s explore the features and benefits of THWN-2 electrical wire:

Heat and Temperature Resistance: THWN-2 wire is engineered to withstand high temperatures, making it suitable for underground installations where the wire may come into contact with heat sources. It has the ability to handle higher current loads without overheating or degrading, ensuring the safe and reliable operation of your electrical system.

Water and Moisture Resistance: One of the key advantages of THWN-2 wire is its excellent resistance to moisture. The nylon coating on the wire provides an additional layer of protection, preventing water penetration and corrosion. This makes THWN-2 wire a reliable choice for underground installations where exposure to moisture is a concern, such as in wet locations or areas prone to heavy rainfall.

UV Resistance: THWN-2 wire is also designed to resist the damaging effects of prolonged exposure to sunlight. The nylon coating helps to protect the wire from UV rays, preventing degradation and ensuring long-term performance in outdoor environments. This UV resistance is particularly important for installations where the wire will be exposed to direct sunlight, such as outdoor lighting projects.

Chemical Resistance: THWN-2 wire is resistant to a wide range of chemicals. This makes it suitable for installations in areas where exposure to corrosive substances, such as fertilizers or cleaning agents, is a possibility. The chemical resistance helps to ensure the longevity of the wire and maintain its electrical conductivity over time.

Flexibility and Ease of Installation: THWN-2 wire is known for its flexibility, making it easy to work with during installation. Its pliability allows for straightforward routing and maneuvering, even in tight spaces or around obstacles. This flexibility saves time and effort during the installation process, resulting in a smoother and more efficient project.

Compliance with Building Codes: THWN-2 wire is designed to meet the requirements outlined by local building codes and regulations for underground electrical installations. By choosing THWN-2 wire, you can ensure that your installation meets the necessary standards for electrical wiring and maintains a high level of safety and reliability.

When working with THWN-2 wire, it is essential to follow proper installation techniques and safety guidelines. This includes selecting the appropriate wire size based on the electrical load, using proper connectors for secure connections, and ensuring that all wiring is protected by conduit when required by local codes. Consulting a licensed electrician is recommended to ensure compliance and safety during the installation process.

In summary, THWN-2 electrical wire is a reliable and versatile option for underground installations. Its heat and water resistance, UV resistance, flexibility, and compliance with building codes make it well-suited for a variety of outdoor electrical projects. By choosing THWN-2 wire and following proper installation practices, you can create a robust and long-lasting underground electrical system.

When running electrical wire underground, use a type of wire specifically designed for direct burial, such as UF (underground feeder) cable. This type of wire is moisture and corrosion resistant, and suitable for burial without the need for conduit.

Direct Burial Electrical Wire

Direct burial electrical wire is a type of wire that is specifically designed to be buried directly in the ground without the need for conduit. It offers a convenient and efficient solution for underground electrical installations. Let’s delve into the features and benefits of direct burial electrical wire:

Durable and Protective Jacket: Direct burial wire comes with a rugged outer jacket that provides protection against moisture, chemicals, and physical damage. This jacket is designed to withstand the rigors of being buried underground, ensuring the longevity and reliability of the wire. The durable jacket shields the wire from the elements, preventing water intrusion and potential corrosion.

Simplicity of Installation: Direct burial wire eliminates the need for conduit, making the installation process simpler and more cost-effective. The absence of conduit eliminates the extra steps of connecting wires to conduit, reducing installation time and labor. This streamlined installation process is especially advantageous for large projects or areas where trenching and burying conduit may be challenging.

Customizable Wire Sizes: Direct burial wire is available in various gauges or wire sizes to accommodate different electrical loads. It is crucial to select the appropriate wire size based on the anticipated electrical demand to ensure optimal performance and prevent overheating. Consulting with an electrician or following local building codes can help determine the correct wire size for your specific project.

Flexibility and Ease of Handling: Direct burial wire is typically flexible, allowing for easy maneuverability during installation. This flexibility enables the wire to navigate bends, twists, and other obstacles without compromising its integrity. The ease of handling ensures a smooth installation process, minimizing the risk of damage to the wire or disruptions to the surrounding landscape.

Versatile Applications: Direct burial wire is used in a wide range of applications. It can be used for outdoor lighting systems, irrigation systems, underground circuits, and other outdoor electrical projects. Its versatility makes it an excellent choice for various residential, commercial, and industrial applications.

Compliance with Building Codes: It is crucial to ensure that the direct burial wire you choose complies with local building codes and regulations. Local codes often dictate the minimum burial depth, wire sizing, and other specifications for underground electrical installations. Adhering to these codes ensures the safety and legality of your project.

When using direct burial wire, it is essential to handle it with care and take proper safety precautions. Before installation, always make sure to de-energize the area and follow standard electrical safety practices. Additionally, using proper wire connectors and burying the wire at the appropriate depth are critical for maintaining the integrity of the electrical system.

In summary, direct burial electrical wire offers a practical and efficient solution for underground installations. Its durable jacket, simplified installation process, customizable wire sizes, and versatility make it an excellent choice for various outdoor electrical projects. By selecting the appropriate direct burial wire and following proper installation techniques, you can create a reliable and long-lasting underground electrical system.

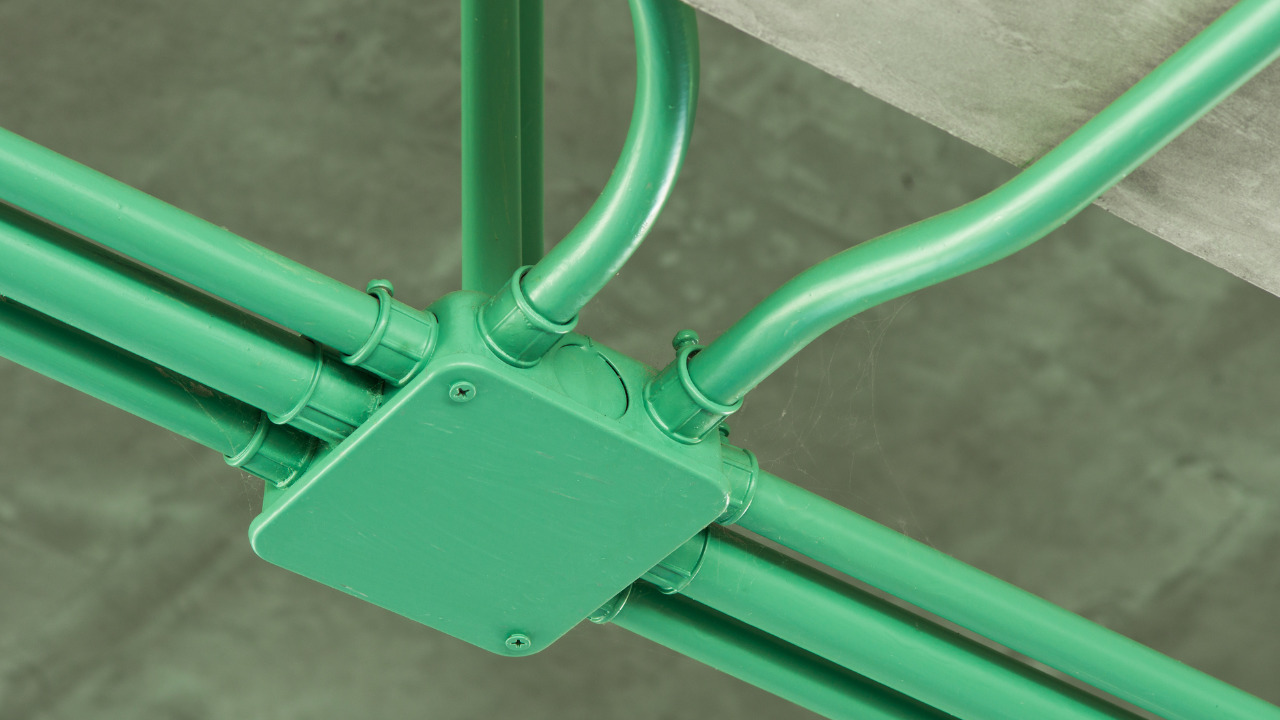

Conduit Options for Underground Electrical Wiring

When it comes to underground electrical wiring, conduits play a vital role in protecting and housing the wires. Conduits are pipes or tubes that provide a safe enclosure for electrical cables, offering protection against moisture, physical damage, and other potential hazards. Let’s explore some of the common conduit options for underground electrical wiring:

- PVC Conduit: PVC (Polyvinyl Chloride) conduit is one of the most widely used options for underground electrical wiring. It is affordable, lightweight, and resistant to moisture, chemicals, and corrosion. PVC conduit is available in various sizes, making it suitable for different wire capacities. It is easy to cut, install, and connect, making it a popular choice for residential and light commercial installations.

- HDPE Conduit: High-Density Polyethylene (HDPE) conduit is a flexible and durable option for underground electrical wiring. It is resistant to impact, UV rays, and a wide range of chemicals. HDPE conduit is often used in areas where flexibility is needed, as it can be bent and molded around obstacles without the need for additional fittings or connectors. It is commonly used in industrial, agricultural, and utility applications.

- Rigid Metal Conduit: Rigid Metal Conduit (RMC) is a robust and sturdy option for underground electrical wiring. Made of steel, RMC provides excellent protection against mechanical damage, fire, and impact. It is typically used in commercial and industrial applications where extra protection is required. RMC requires threaded fittings and connectors for installation and offers high tensile strength and reliability.

- EMT Conduit: Electrical Metallic Tubing (EMT) is a lightweight and economical option for underground electrical wiring. It is made of thin-walled steel and is commonly used in residential and light commercial installations. EMT conduit is easy to bend and install and requires standard fittings and connectors for connections. It provides good protection against physical damage and can be used in both indoor and outdoor applications.

- Flexible Metal Conduit: Flexible Metal Conduit (FMC) is a flexible option that provides ease of installation in underground electrical wiring. It is made of interlocking metal strips with a plastic or rubber coating, allowing it to be bent and maneuvered through tight spaces. FMC provides good protection against physical damage and can be a suitable choice for areas with limited access or where flexibility is essential.

When selecting a conduit for your underground electrical wiring, it is essential to consider factors such as the type of installation, environmental conditions, local building codes, and the specific needs of your project. Consulting with a licensed electrician or knowledgeable professional can help you determine the most appropriate conduit option.

It is also important to note that conduits alone may not provide adequate protection against water ingress. Choosing cables specifically designed for direct burial or using conduit with proper seals and fittings can enhance the water resistance of the electrical system.

Proper installation techniques, such as ensuring proper burial depth and utilizing appropriate connectors, are crucial for a successful and safe underground electrical wiring project. By selecting the right conduit and employing professional installation practices, you can ensure a reliable and long-lasting underground electrical system.

Advantages and Disadvantages of Running Electrical Wire Underground

Running electrical wire underground offers several advantages and disadvantages compared to installing overhead or exposed wiring. Understanding these pros and cons can help you make an informed decision regarding the most appropriate wiring method for your specific needs. Let’s explore the advantages and disadvantages of running electrical wire underground:

Advantages:

- Aesthetics: Underground electrical wiring is hidden from view, providing a cleaner and more aesthetically pleasing appearance. It eliminates the need for exposed wires and overhead cables, contributing to a neater and more professional look, especially in outdoor spaces.

- Safety: Underground wiring reduces the risk of accidental contact with electrical wires, minimizing the potential for injury and electrical hazards. By burying the wires, they are protected from physical damage, tampering, and environmental elements, enhancing overall safety for you and your surroundings.

- Weather Resistance: Underground wiring is more resistant to weather conditions, such as high winds, ice, and heavy rain. It is less likely to be affected by external factors, leading to a more reliable electrical system, even during inclement weather.

- Durability: Properly installed underground electrical wiring can offer enhanced durability and longevity. It is protected from harsh environmental elements, such as UV rays, extreme temperatures, and moisture, which can lead to deterioration and premature wear on exposed wiring.

- Flexible Placement: Underground wiring allows for more flexibility in the placement of electrical outlets, lighting, and other components. It can be installed in various locations without the restrictions imposed by overhead wiring, providing more freedom to design and configure your electrical system according to your specific needs and preferences.

- No Landscape Obstructions: With underground wiring, there are no unsightly poles or overhead lines obstructing your view or interfering with landscaping. This allows for greater freedom in designing and maintaining outdoor spaces, without the need to work around exposed electrical infrastructure.

Disadvantages:

- Installation Complexity: Underground electrical wiring typically requires more preparation, planning, and labor compared to overhead installations. It involves digging trenches or using conduit systems, which adds to the complexity and time required for installation.

- Higher Cost: Underground electrical wiring can be more expensive upfront due to the additional materials needed, such as conduit, and the labor-intensive process of burying the wires. The cost may also increase if excavation or landscaping work is needed for installation in existing areas or properties.

- Limited Accessibility for Repairs: In the event of electrical system repairs or modifications, underground wiring may be more challenging to access compared to overhead wiring. This can result in increased repair costs and potential disruptions to the surrounding area, especially if additional excavation or digging is required.

- Code Requirements: Underground electrical wiring must comply with specific local building codes and regulations. These codes outline requirements for burial depth, conduit usage, wire types, and other safety considerations that must be met. Failure to adhere to these codes can result in potential safety hazards and legal issues.

It is crucial to weigh the advantages and disadvantages of running electrical wire underground based on your individual circumstances. Consider factors such as aesthetics, safety, weather resistance, durability, and the associated costs and complexities. Consulting with a licensed electrician or professional can help you make an informed decision and ensure compliance with local regulations.

Overall, running electrical wire underground offers numerous benefits, including improved safety, aesthetics, durability, and flexibility. However, it is important to carefully consider the disadvantages and assess how they may impact your specific project before choosing the underground wiring option.

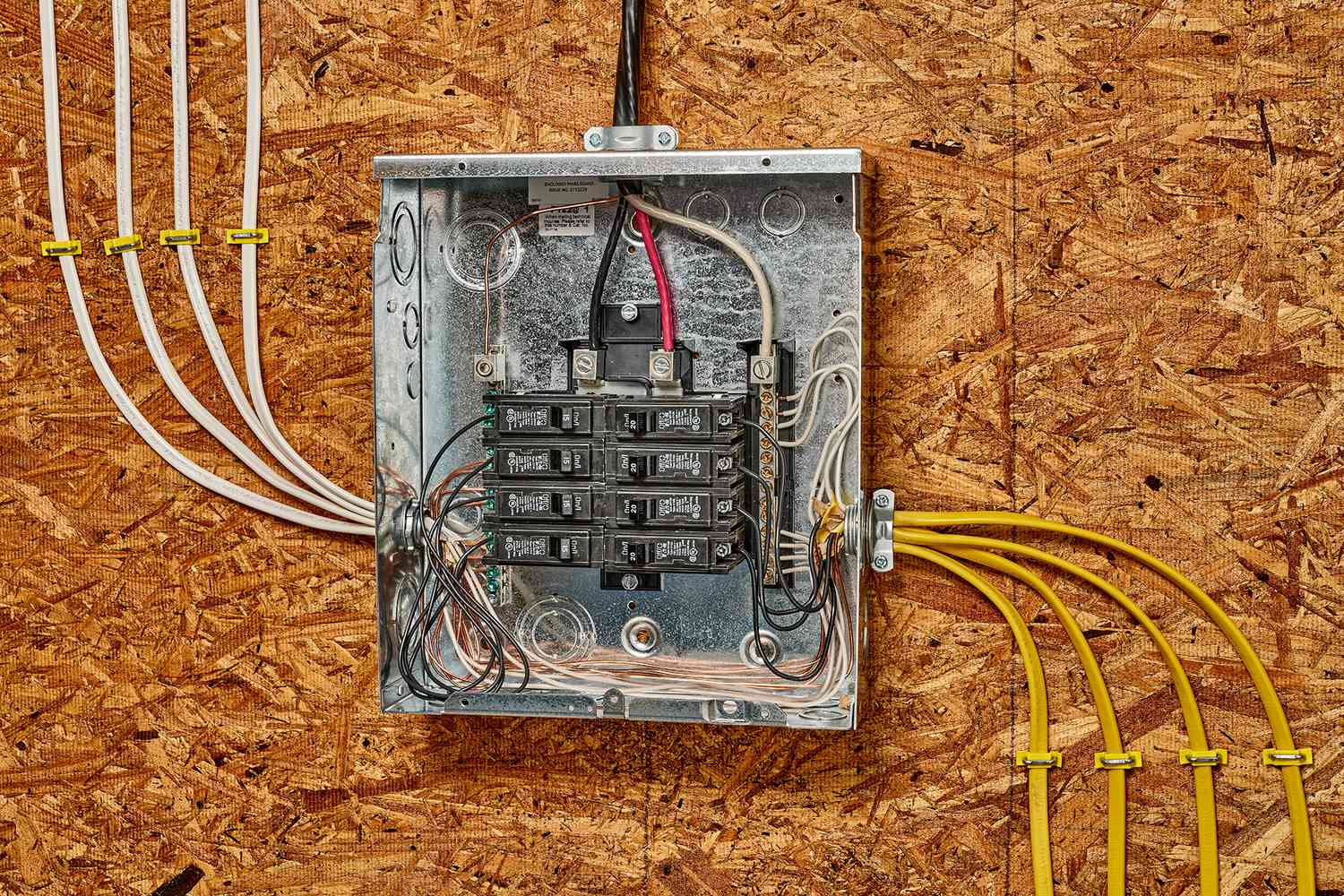

Steps to Safely Install Electrical Wire Underground

Installing electrical wire underground requires careful planning, adherence to safety guidelines, and compliance with local building codes. Follow these essential steps to ensure a safe and successful underground electrical wire installation:

- Research Local Building Codes: Familiarize yourself with the specific requirements and regulations regarding underground electrical wiring in your area. Local building codes will dictate guidelines for wire types, burial depths, conduit usage, grounding, and other safety considerations. Ensure that your installation plan aligns with these codes.

- Create a Plan: Determine the route for your underground wiring and mark the trench or pathway where the wire will be installed. Consider the location of existing utilities and any potential obstructions or landscaping features that may need to be taken into account. Proper planning minimizes the risk of accidental damage to existing infrastructure and helps ensure an efficient installation process.

- Gather Materials and Tools: Collect all the necessary materials and tools for the project, including the appropriate gauges and types of electrical wire, conduit (if required), connectors, junction boxes, and grounding materials. Safety equipment, such as gloves, safety glasses, and ear protection, should also be on hand.

- Call Utility Companies: Before digging, contact your local utility companies to arrange for utility markings. They will identify the locations of underground utilities to avoid accidental damage during excavation. This step is crucial for safety and can save you from costly repairs or disruptions to essential services.

- Excavate the Trench: Dig a trench along the planned pathway for the wire installation. The depth of the trench will depend on local codes and the type of wire being used. Typically, a depth of 18-24 inches is common for residential installations. Ensure that the trench is wide enough to accommodate the wire and any necessary conduits or protective measures.

- Install Conduit (if necessary): If required by local codes or to provide additional protection for the electrical wire, install the appropriate conduit in the trench. Secure the conduit using proper connectors, making sure it is level and positioned correctly. Attach conduit bodies at appropriate intervals for bends and turns in the trench route.

- Route and Connect the Electrical Wire: Carefully feed the electrical wire through the conduit or directly into the trench if no conduit is needed. Make sure the wire is properly sized for the electrical load and follows the recommended wire-routing practices. Use appropriate connectors to join wire segments and ensure secure connections. Place the wire in junction boxes where necessary and make all required electrical connections.

- Bury the Wire: Once the wire is installed and connections are made, carefully backfill the trench, ensuring that the wire and any conduit are adequately protected. Follow local codes regarding the minimum burial depth and any requirements for warning tape or markers. Take care to avoid any damage to the wire during the backfilling process.

- Test and Inspect: Before completing the project, conduct a thorough test and inspection of the installed electrical system. Ensure that all connections are secure and properly grounded. Test the voltage, continuity, and functionality of the system using appropriate testing equipment. Verify that the system operates as intended and meets safety standards.

- Secure the Area: Once the installation is complete and the system has passed the necessary tests, secure the area and restore any landscaping or surface features that were disrupted during the installation process. Clean up any debris and ensure that the area is safe and accessible.

It is essential to consult with a licensed electrician or professional to ensure compliance with local regulations, safety protocols, and proper installation techniques. Their expertise will help ensure a safe and reliable underground electrical wiring installation.

By following these steps and taking the necessary precautions, you can install electrical wire underground in a safe and efficient manner, providing reliable power to your outdoor projects while maintaining compliance with electrical standards.

Conclusion

Running electrical wire underground offers numerous benefits, including enhanced safety, improved aesthetics, and increased durability. However, it is essential to carefully consider the factors involved and follow proper installation techniques to ensure a successful project. By understanding local building codes, selecting the appropriate type of wire, and employing the right conduit options (if necessary), you can create a reliable and long-lasting underground electrical system.

Before embarking on an underground wiring project, be sure to research and familiarize yourself with the specific requirements and regulations in your area. Compliance with these codes ensures that your installation meets safety standards and avoids any legal complications.

Choosing the right type of wire for your underground installation is crucial. PVC-coated electrical wire provides excellent moisture and chemical resistance, UF-B wire is designed for direct burial applications, THWN-2 wire offers high-temperature and water resistance, and direct burial wire eliminates the need for conduit. Assess the environmental conditions, electrical load requirements, and the specific needs of your project to determine the most suitable wire type.

Conduit options also play a significant role in protecting the underground electrical wiring. PVC conduit offers affordability and resistance to moisture and corrosion, HDPE conduit is flexible and durable, RMC provides robust protection, EMT offers a lightweight and cost-effective option, and FMC provides flexibility in installation. Choose the appropriate conduit based on the specific requirements of your project.

During installation, carefully follow the necessary steps and safety guidelines. This includes proper excavation, conduit placement, wire routing, grounding, and testing. Adhering to these steps ensures the safety and reliability of your underground electrical system.

It is crucial to consult with a licensed electrician or professional experienced in underground electrical wiring to ensure compliance with local regulations and to receive expert guidance throughout the installation process. Their expertise will help you navigate the complexities and ensure a successful project.

In conclusion, running electrical wire underground provides a range of benefits in terms of safety, aesthetics, and durability. By understanding local codes, selecting the appropriate wire and conduit options, following proper installation techniques, and seeking professional guidance, you can create a reliable and efficient underground electrical system that meets your specific needs while ensuring the safety and compliance of your installation.

Frequently Asked Questions about What Electrical Wire To Run Underground

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Electrical Wire To Run Underground”