Home>Furniture & Design>Interior Design Trends>How To Solder Glass Together

Interior Design Trends

How To Solder Glass Together

Modified: February 18, 2024

Learn how to solder glass together with our expert tips and techniques. Discover the latest interior design trends for creating stunning glass art pieces. Unlock the secrets to mastering glass soldering for your next interior design project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Soldering glass is a captivating and intricate art form that allows for the creation of stunning glass pieces, from delicate stained glass windows to intricate glass jewelry. This technique involves joining pieces of glass together using solder, a metal alloy with a low melting point. The process requires precision, patience, and a keen eye for detail, making it a rewarding endeavor for both beginners and experienced artisans.

Soldering glass is not only a practical skill but also a form of artistic expression. It offers a unique way to bring together various glass elements, creating beautiful and functional objects that can adorn homes, offices, and public spaces. Whether you are a hobbyist looking to explore a new craft or a professional seeking to expand your repertoire, mastering the art of soldering glass opens up a world of creative possibilities.

In this comprehensive guide, we will delve into the intricacies of soldering glass, exploring the fundamental techniques, tools, and materials required to embark on this captivating journey. From understanding the basics of soldering glass to selecting the right tools and preparing glass surfaces for soldering, we will provide you with the knowledge and insights needed to embark on your soldering glass adventure. Whether you aspire to create intricate stained glass panels, decorative glass ornaments, or personalized gifts, this guide will equip you with the essential know-how to bring your creative visions to life.

Embarking on the journey of soldering glass is an opportunity to unleash your creativity and immerse yourself in a timeless craft that has captivated artisans for centuries. As we delve into the nuances of this art form, you will discover the joy of transforming raw materials into exquisite works of art, each bearing the unique imprint of your creativity and skill. So, let's embark on this enchanting journey into the world of soldering glass, where precision meets artistry, and imagination knows no bounds.

Key Takeaways:

- Soldering glass is a captivating art form that requires precision and patience. It involves joining pieces of glass using solder, creating stunning and enduring works of art.

- Choosing the right tools and materials is crucial for successful glass soldering. From temperature-controlled soldering irons to high-quality solder and flux, each component plays a vital role in creating strong and visually appealing soldered joints.

Read more: How To Solder Stained Glass

Understanding the Basics of Soldering Glass

Soldering glass is a meticulous and intricate process that involves joining pieces of glass together using solder, a fusible metal alloy. This technique requires a deep understanding of the properties of glass and the behavior of solder when applied to it. The fundamental principle of soldering glass lies in creating a strong and seamless bond between individual glass pieces, ensuring structural integrity and aesthetic appeal.

One of the key aspects of understanding the basics of soldering glass is comprehending the behavior of different types of glass when subjected to heat. Glass, being a non-metallic and amorphous material, responds uniquely to the application of heat during the soldering process. It is essential to consider the coefficient of expansion of the glass, as different types of glass expand and contract at varying rates when exposed to heat. This knowledge is crucial in preventing thermal stress and potential breakage during the soldering process.

Furthermore, understanding the flow and adhesion properties of solder is paramount in achieving a successful soldered joint. Solder, typically composed of tin and lead, melts at a relatively low temperature and flows into the crevices between glass pieces, creating a secure bond upon cooling. The ability to control the flow of solder and achieve uniform adhesion is a skill that distinguishes proficient glass soldering artisans.

Additionally, comprehending the role of flux in the soldering process is essential. Flux serves multiple purposes, including removing oxides from the metal surface, promoting solder flow, and preventing oxidation of the molten solder. Choosing the appropriate flux and understanding its application is crucial in ensuring clean and durable soldered joints.

Moreover, mastering the art of soldering glass involves familiarity with different soldering techniques, such as copper foil and lead came methods. Each technique has its unique characteristics and applications, and understanding their nuances is essential for executing precise and visually appealing soldered joints.

In essence, understanding the basics of soldering glass encompasses a holistic grasp of the properties of glass, the behavior of solder, the role of flux, and the various soldering techniques. This foundational knowledge forms the bedrock upon which the artistry and craftsmanship of soldering glass are built, paving the way for the creation of exquisite and enduring glass pieces.

Choosing the Right Soldering Tools and Materials

Selecting the appropriate soldering tools and materials is a critical step in the journey of mastering the art of soldering glass. The right equipment not only facilitates precision and efficiency but also contributes to the overall quality and durability of the soldered joints. Here's a comprehensive overview of the essential tools and materials required for successful glass soldering:

Soldering Iron:

The soldering iron is the cornerstone of the soldering process. When soldering glass, it is crucial to use a temperature-controlled soldering iron specifically designed for delicate glasswork. Opt for a soldering iron with adjustable temperature settings to accommodate different types of glass and solder. Additionally, ensure that the soldering iron features a fine, pointed tip to enable precise application of heat to the solder and glass joint.

Solder:

Choosing the right solder is pivotal in achieving strong and visually appealing soldered joints. For soldering glass, a lead-based solder with a high tin content is commonly used due to its low melting point and excellent flow characteristics. It is advisable to select a solder with a composition of 60% tin and 40% lead, as this combination offers optimal adhesion and malleability without compromising strength.

Read more: How To Put Glass Back Together

Flux:

Flux is an indispensable component in the soldering process, serving to remove oxides from the metal surface, promote solder flow, and prevent oxidation of the molten solder. When selecting flux for soldering glass, opt for a non-corrosive, low-temperature flux specifically formulated for use with delicate glass surfaces. It is essential to choose a flux that is compatible with the solder alloy being used to ensure clean and durable soldered joints.

Glass Cutter and Grinder:

Preparing glass pieces for soldering necessitates precise cutting and shaping. A high-quality glass cutter equipped with a sharp cutting wheel is essential for cleanly scoring and breaking glass sheets into desired shapes and sizes. Additionally, a glass grinder with diamond-coated bits is indispensable for refining the edges of glass pieces, ensuring a snug fit and seamless soldered joints.

Safety Equipment:

Prioritizing safety during the soldering process is paramount. Essential safety equipment includes protective eyewear, heat-resistant gloves, and a well-ventilated workspace to mitigate exposure to fumes. Additionally, a fume extractor or respirator may be employed when working with solder and flux to minimize inhalation of potentially harmful vapors.

Additional Materials:

Other essential materials include copper foil or lead came, depending on the chosen soldering technique, as well as glass cleaner and soft cloths for preparing glass surfaces before soldering and for post-soldering cleanup.

By carefully selecting the right soldering tools and materials, artisans can lay a solid foundation for executing precise, durable, and visually stunning soldered glass pieces. Investing in high-quality equipment and materials not only enhances the soldering experience but also contributes to the creation of enduring works of art that showcase the beauty and versatility of soldered glass.

Preparing the Glass Surfaces for Soldering

Preparing the glass surfaces for soldering is a crucial step that sets the stage for achieving strong, seamless, and visually appealing soldered joints. This process involves meticulous attention to detail and precision to ensure that the glass pieces are clean, properly fitted, and conducive to the soldering process.

The first step in preparing glass surfaces for soldering is to thoroughly clean the glass pieces. Any dust, debris, or residues on the glass surfaces can hinder the adhesion of solder and compromise the integrity of the soldered joint. Using a gentle glass cleaner and soft, lint-free cloths, artisans meticulously clean the glass pieces, ensuring that the surfaces are free from contaminants that could impede the soldering process.

Once the glass pieces are clean, the next crucial aspect of preparation involves fitting the pieces together with precision. Whether utilizing the copper foil or lead came method, ensuring that the glass pieces fit snugly and seamlessly is essential for creating strong and visually appealing soldered joints. Artisans carefully assess the fit of the glass pieces, making any necessary adjustments using a glass grinder to refine the edges and achieve a precise fit.

In the copper foil method, the edges of the glass pieces are wrapped with copper foil, which serves as the foundation for the soldered joint. The foil not only facilitates the adhesion of solder but also provides structural support to the glass pieces. Artisans meticulously apply the copper foil to the edges of the glass, ensuring that it adheres smoothly and uniformly to create a seamless surface for soldering.

In the lead came method, artisans use H-shaped lead came strips to hold the glass pieces together. Prior to soldering, the lead came is carefully fitted around the edges of the glass pieces, ensuring a secure and uniform hold. This meticulous fitting process is essential for creating strong and durable soldered joints, as it establishes a stable framework for the application of solder.

Furthermore, artisans may opt to apply flux to the prepared glass surfaces before soldering. Flux serves to facilitate the flow of solder and prevent oxidation, ensuring clean and durable soldered joints. By applying flux to the prepared glass surfaces, artisans prime the glass pieces for the soldering process, setting the stage for precise and uniform adhesion of solder.

In essence, preparing the glass surfaces for soldering demands meticulous attention to cleanliness, precise fitting, and, if applicable, the application of flux. This preparatory phase lays the groundwork for executing seamless and enduring soldered joints, ensuring that the resulting glass pieces exhibit both structural integrity and aesthetic appeal.

Soldering the Glass Together

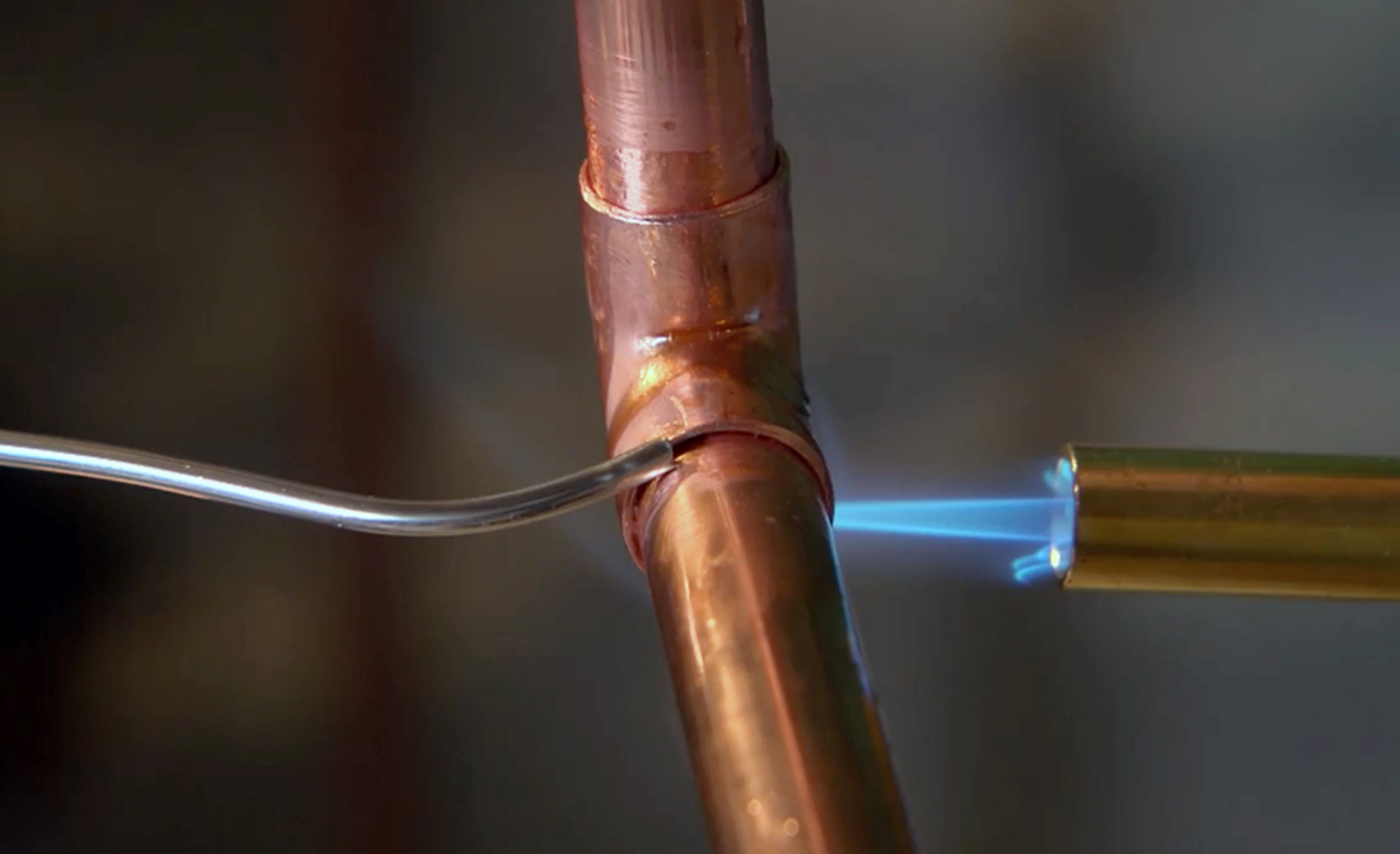

Soldering the glass together is the pivotal stage where the meticulous preparation and precise craftsmanship culminate in the creation of seamless and enduring bonds between glass pieces. This intricate process demands a delicate balance of heat control, solder application, and attention to detail to achieve strong, visually appealing, and structurally sound soldered joints.

The first step in soldering the glass together involves heating the soldering iron to the appropriate temperature, taking into account the type of glass and solder being used. It is essential to exercise caution and precision during the heating process, as overheating can lead to thermal stress and potential damage to the glass. With the soldering iron at the optimal temperature, artisans carefully apply heat to the solder and glass joint, allowing the solder to melt and flow evenly between the prepared glass surfaces.

As the solder liquefies, artisans skillfully maneuver the soldering iron along the seams, ensuring that the molten solder uniformly adheres to the copper foil or lead came and fuses with the glass surfaces. This delicate maneuvering requires a steady hand and a keen eye for detail, as artisans work to create smooth and uniform soldered joints that seamlessly unite the glass pieces.

In the copper foil method, artisans meticulously guide the soldering iron along the wrapped edges of the glass pieces, allowing the molten solder to bond with the copper foil and form a secure and visually appealing soldered joint. The controlled application of heat and solder is essential in achieving a strong and durable bond that complements the inherent beauty of the glass.

Similarly, in the lead came method, artisans navigate the soldering iron along the lead came seams, ensuring that the molten solder adheres uniformly to the lead came and the glass surfaces. This meticulous process results in robust and visually striking soldered joints that accentuate the structural integrity of the glass assembly.

Throughout the soldering process, artisans maintain a delicate balance of heat application and solder control, working methodically to create seamless and enduring bonds between the glass pieces. The artistry and precision displayed during this stage are instrumental in shaping the final outcome, where individual glass elements coalesce into a unified and captivating work of art.

In essence, soldering the glass together is a testament to the fusion of technical skill and artistic vision, where the transformative power of heat and solder converges to elevate raw materials into exquisite and enduring creations. This stage marks the culmination of meticulous preparation and precise execution, giving rise to soldered glass pieces that embody both strength and beauty, showcasing the timeless allure of this captivating art form.

Finishing and Cleaning the Soldered Glass Piece

After the meticulous process of soldering the glass pieces together, the final steps involve finishing and cleaning the soldered glass piece to enhance its visual appeal and ensure its longevity. This phase is essential for refining the soldered joints, removing any residual flux, and imparting a polished finish to the completed glass assembly.

The finishing touches begin with inspecting the soldered joints to ensure uniformity, strength, and aesthetic appeal. Artisans meticulously examine each soldered seam, addressing any irregularities or excess solder to achieve a smooth and visually pleasing surface. This attention to detail is crucial in refining the overall appearance of the soldered glass piece, elevating it from a collection of individual elements to a cohesive and harmonious work of art.

Following the inspection, the next step involves cleaning the soldered glass piece to remove any flux residue and impart a pristine finish. Flux, while essential during the soldering process, can leave behind a thin film that detracts from the visual clarity and luster of the glass. To address this, artisans employ a gentle glass cleaner and soft, lint-free cloths to delicately remove any flux residue, ensuring that the soldered joints and glass surfaces gleam with clarity and brilliance.

Once the flux residue is thoroughly removed, artisans may opt to apply a glass polish or wax to the soldered glass piece, further enhancing its luster and providing a protective coating. This final touch not only accentuates the inherent beauty of the glass but also safeguards the soldered joints and surfaces, contributing to the longevity and resilience of the completed piece.

In addition to visual refinement, finishing and cleaning the soldered glass piece also encompasses the structural integrity of the assembly. Artisans carefully examine the soldered joints to confirm their strength and durability, making any necessary adjustments to reinforce the bonds between the glass pieces. This meticulous assessment ensures that the completed glass assembly not only exudes visual allure but also embodies resilience and longevity, standing the test of time as a testament to the artistry and craftsmanship of soldering glass.

In essence, the process of finishing and cleaning the soldered glass piece is a transformative phase that elevates the completed assembly to a state of refined elegance and enduring beauty. Through meticulous inspection, cleaning, and structural assessment, artisans impart a sense of artistry and permanence to the soldered glass piece, culminating in a creation that captivates the eye and stands as a testament to the timeless allure of this intricate and captivating art form.

Conclusion

In conclusion, the art of soldering glass is a captivating and intricate craft that marries technical precision with artistic expression. Throughout this comprehensive guide, we have delved into the fundamental principles, techniques, and materials essential for mastering the art of soldering glass. From understanding the behavior of glass under heat to selecting the right tools and preparing glass surfaces for soldering, each aspect of this craft embodies a harmonious blend of skill, creativity, and attention to detail.

Embarking on the journey of soldering glass is an opportunity to unleash creativity and immerse oneself in a timeless art form that has captivated artisans for centuries. The process of soldering glass transcends mere technical proficiency; it is an act of transformation, where individual glass elements coalesce into unified and enduring works of art. The fusion of heat, solder, and glass gives rise to pieces that not only exhibit structural integrity but also exude visual allure, captivating the eye and evoking a sense of wonder.

As artisans navigate the intricacies of soldering glass, they embark on a journey of discovery, where each soldered joint becomes a testament to their skill, patience, and artistic vision. The completed glass pieces, whether intricate stained glass panels, decorative ornaments, or functional art pieces, bear the indelible imprint of the artisan's craftsmanship, each telling a unique story through the interplay of light, color, and form.

Furthermore, the art of soldering glass transcends the confines of mere technique; it fosters a deep appreciation for the inherent beauty and versatility of glass as a medium for artistic expression. Through the meticulous process of soldering, artisans breathe life into raw materials, transforming them into enduring creations that adorn homes, enrich public spaces, and serve as cherished gifts that transcend time.

In essence, the art of soldering glass is a celebration of craftsmanship, creativity, and the timeless allure of glass as a medium for artistic expression. As artisans continue to explore and refine their skills in this captivating craft, they contribute to a legacy of enduring beauty, where the transformative power of soldering glass continues to captivate and inspire generations to come.

Frequently Asked Questions about How To Solder Glass Together

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Solder Glass Together”